Shaped container carrier

a container carrier and container holder technology, applied in the direction of containers, flexible covers, tray containers, etc., can solve the problems of fixed shape of the container carrier, inconvenience of not being more modifiable, and not easily usabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

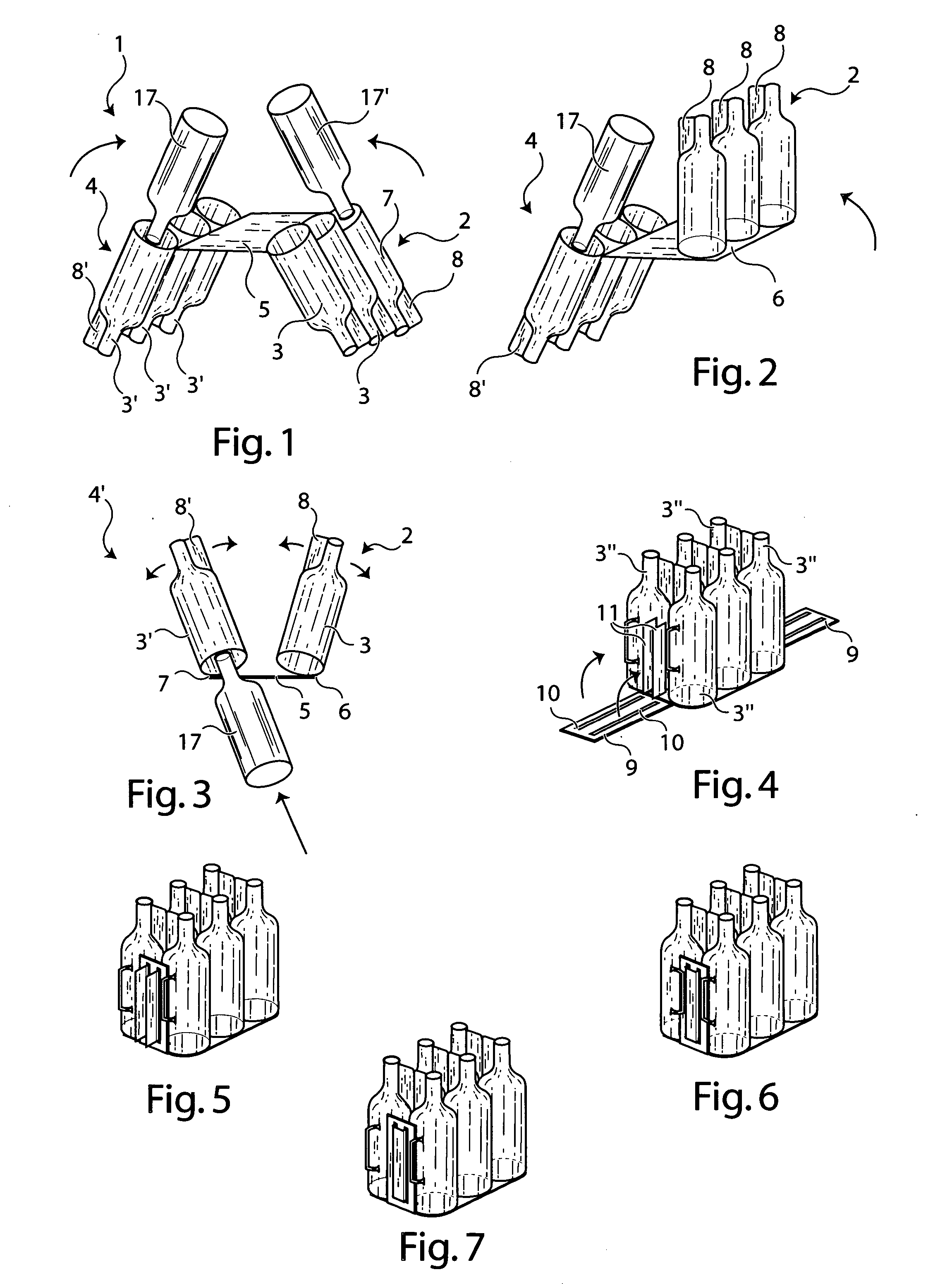

[0084]FIGS. 1-3 show the container carrier according to the invention.

[0085] With reference to FIG. 1, the container carrier 1 in a first loading configuration may be observed. The container carrier comprises a right element 2, provided with three shaped housings 3 for containers, preferably bottles 17, and a similar left element 4, provided with three shaped housings 3′ for containers as well. Each shaped housing 3 and 3′ is open in correspondence with the base of a container from which it takes the shape, and it is preferably (but not necessarily) close in correspondence with the top of the container from which it takes the shape.

[0086] The right element 2 and the left element 4 are hinged on a corresponding side, respectively 6 and 7, of a plane support 5, so as to be capable to rotate each round a corresponding side, as shown in FIGS. 2 and 3, between a first position of loading of containers and a second position of carriage. In the first loading position the base opening of e...

third embodiment

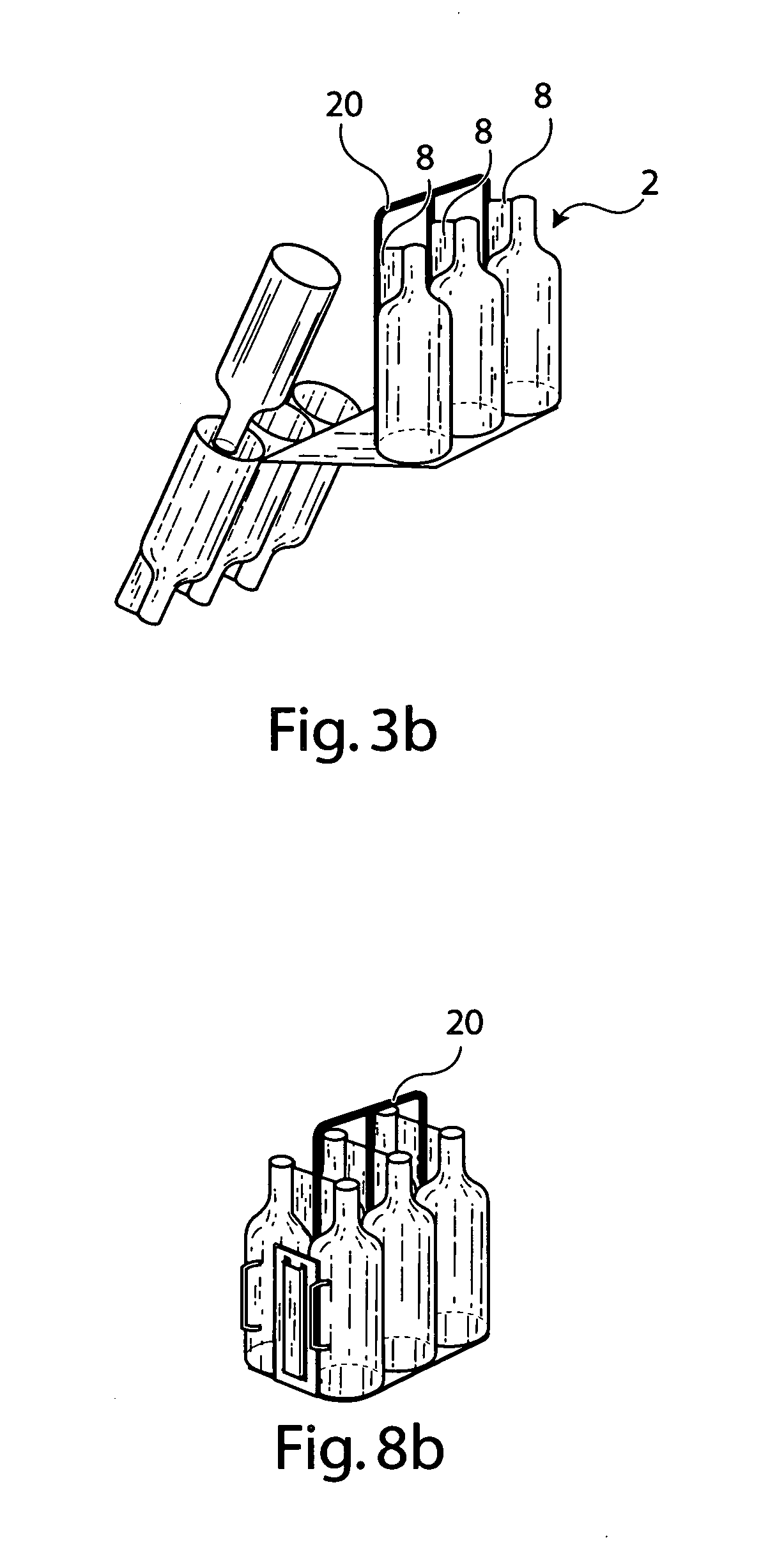

[0093]FIGS. 4-8 show the container carrier according to the invention, wherein the plane support 5 is provided along the short side with two side hinged planes 9, each having two slots 10, apt to interact in a tonguing with two pairs of flaps 11 with which the four corner housings 3″ of the container carrier 1 are provided.

[0094] In order to laterally close the container carrier 1, starting from the configuration of FIG. 4, with the right and left elements 2 and 4 coupled by means of the tongues 8 and 8′, the side hinged planes 9 are raised up till the flaps 11 are inserted into the corresponding slots 10, as shown in FIG. 5. Afterwards, as shown in FIG. 6, one of the two flaps 11 of each pair, emerging from the corresponding slots 10, is bent, preferably towards the other flap 11 of the pair, which is in turn bent on the previously bent flap 11, as shown in FIG. 7. Finally, the so closed container carrier 1 may be carried by means of two handles 12 laterally coupled to two faced co...

fifth embodiment

[0095]FIGS. 9-13 show the container carrier according to the invention.

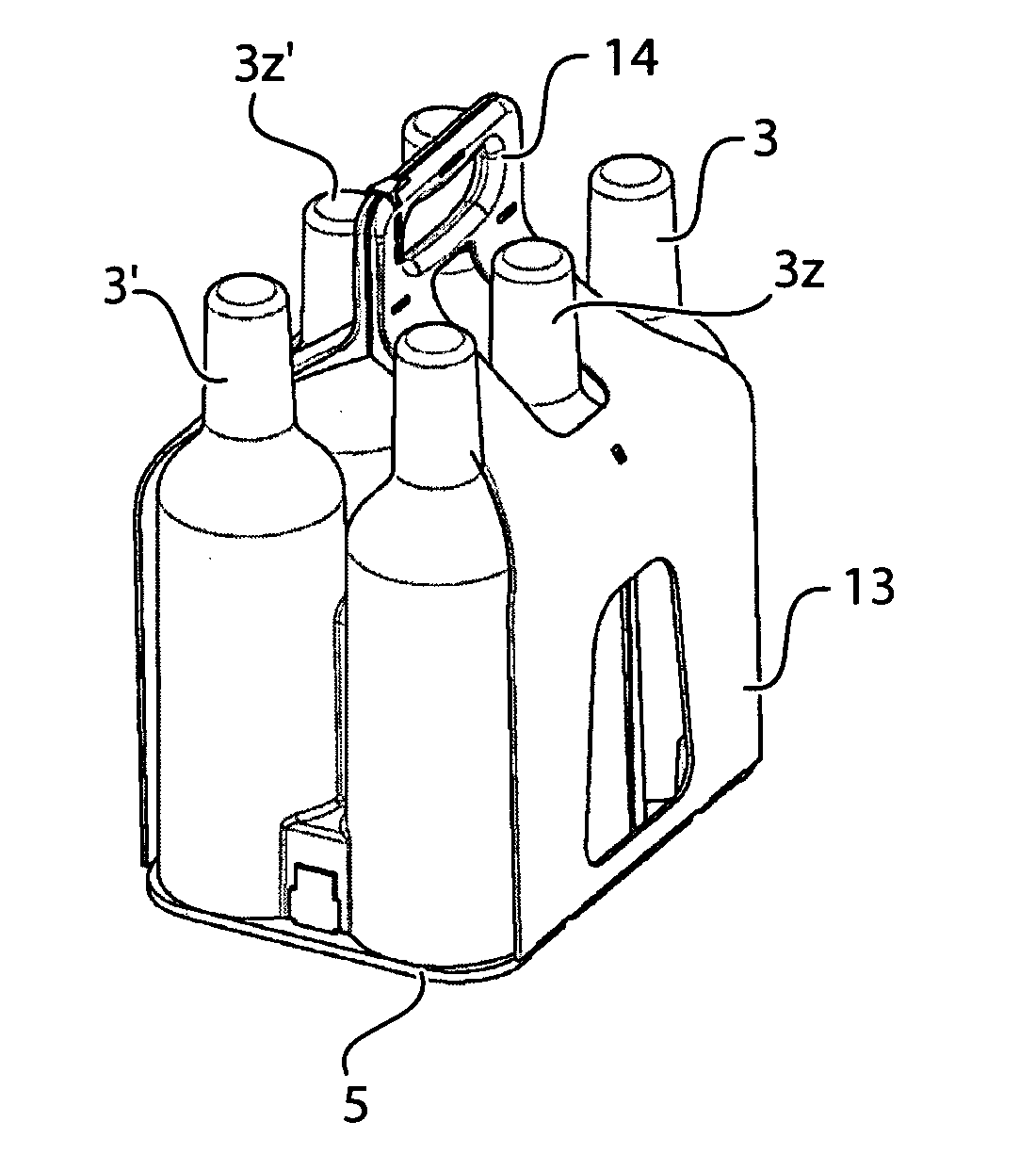

[0096] With reference to FIG. 9, showing the container carrier 1 overturned, it may be observed that the plane support is shaped so as to have a curvilinear perimeter according to the geometric envelope of the base circumferences of the housings 3 and 3′. In particular, the plane support is divided in two right and left portions 5′ and 5″, corresponding to the bases, respectively, of the housings 3 of the right element 2 and of the housings 3′ of the left element 4, wich are hinged one on the other in correspondence with a central axis of symmetry of the plane support. A couple of frames 13 and 13′, provided with corresponding handles 14 and 14′ integral to them, are hinged on the support 5 laterally with respect to the housings 3 and 3′.

[0097] With reference to FIG. 10, it is possible to observe the left element 4 in the second carriage position and the right element 2 in a position intermediate between the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com