Pool cleaner filter bag with zipper closure

a filter bag and zipper closure technology, applied in the field of filter bags, can solve the problems of difficult manipulation for some people, wear and tear of fastener strips, undesirable frayed or fuzzy appearance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

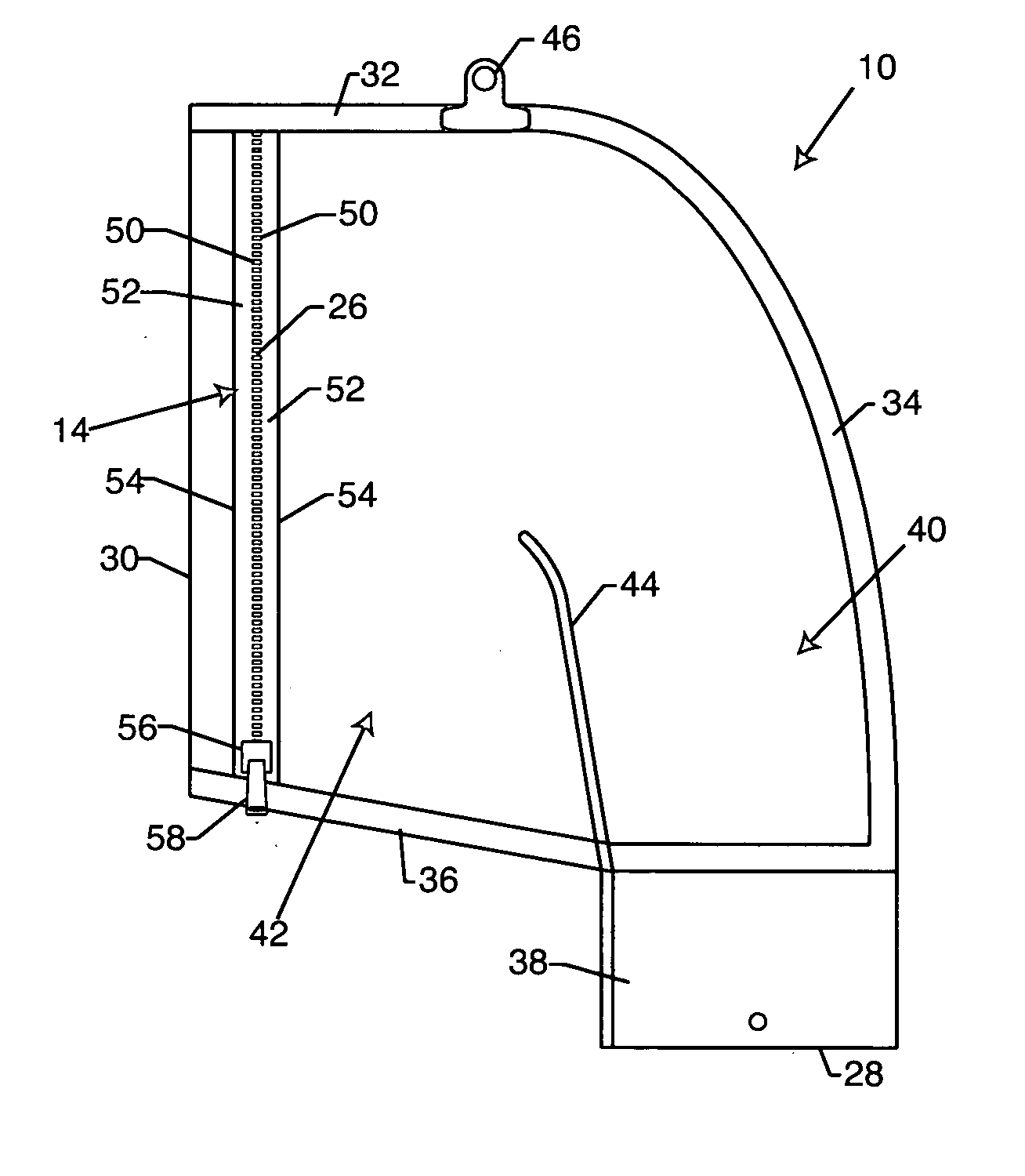

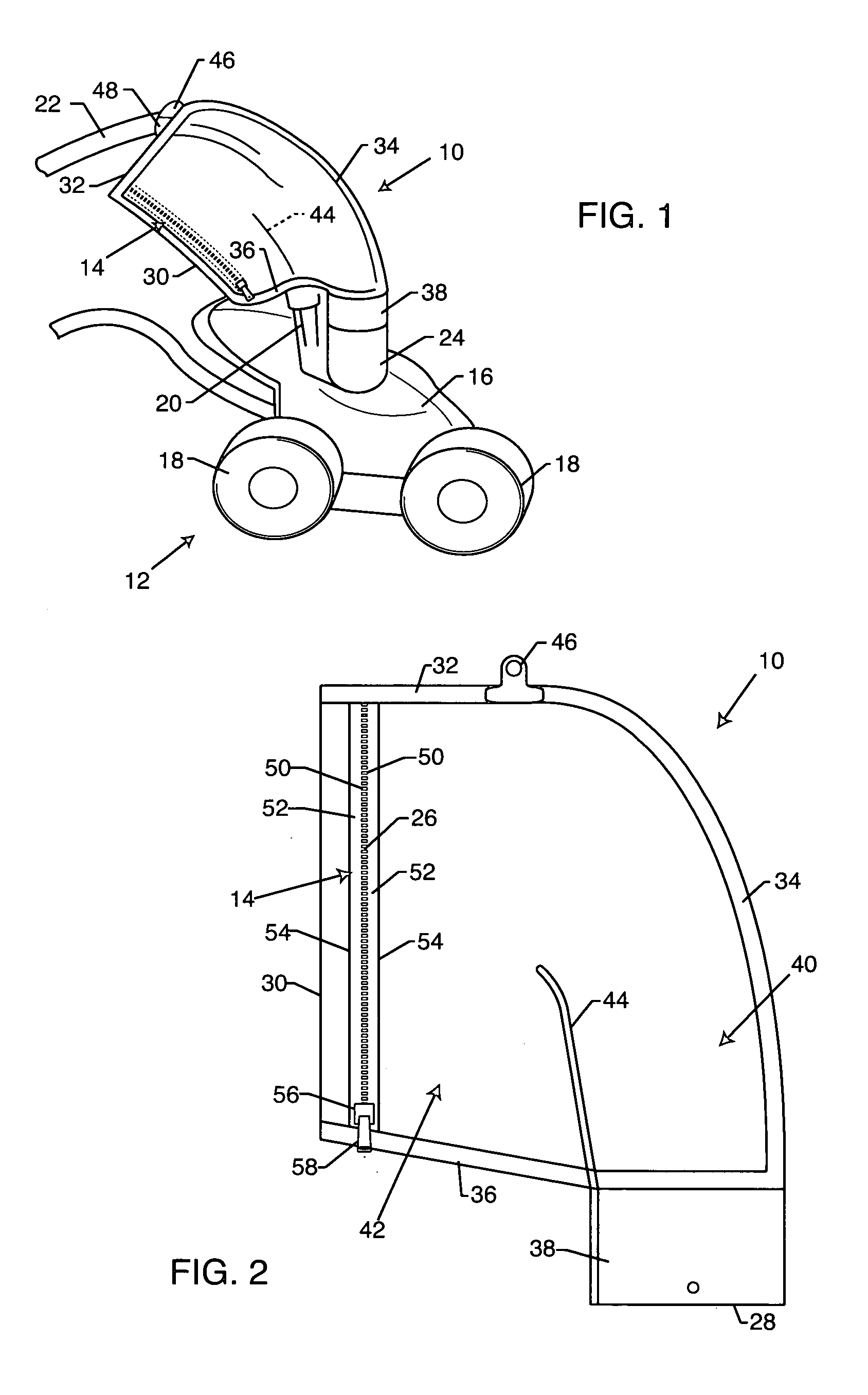

[0016] As shown in the exemplary drawings, a filter bag referred to generally in FIGS. 1 and 2 by the reference numeral 10 is provided for use with a pool cleaner 12 (FIG. 1) for collecting particulate debris such as sand and grit particles, leaves, twigs, and the like. The filter bag 10 is removably mounted onto the pool cleaner 12, and includes a zipper closure 14 for quick and easy emptying collected debris from the bag for appropriate disposal.

[0017] The improved filter bag 10 of the present invention is designed for use with a conventional automatic swimming pool cleaner of the type adapted for substantially random travel throughout the volume of a swimming pool or the like to pick up and collect particulate debris, and / or to assist in suspending or re-suspending such particulate matter so that it can filtered from the pool water by a main filtration system (not shown). FIG. 1 depicts an exemplary pool cleaner 12 generally in accordance with the pool cleaner shown and describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com