Support structure with foldable end cap

a support structure and end cap technology, applied in the direction of girders, instruments, boards, etc., can solve the problems of insufficient applicability, inability to provide significant locking force, and complex assembly and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following description of the illustrated embodiments, reference is made to the accompanying drawings which form a part hereof, and in which is shown by way of illustration, various embodiments in which the invention may be practiced. It is to be understood that other embodiments may be utilized, and structural and functional changes may be made without departing from the scope of the present invention.

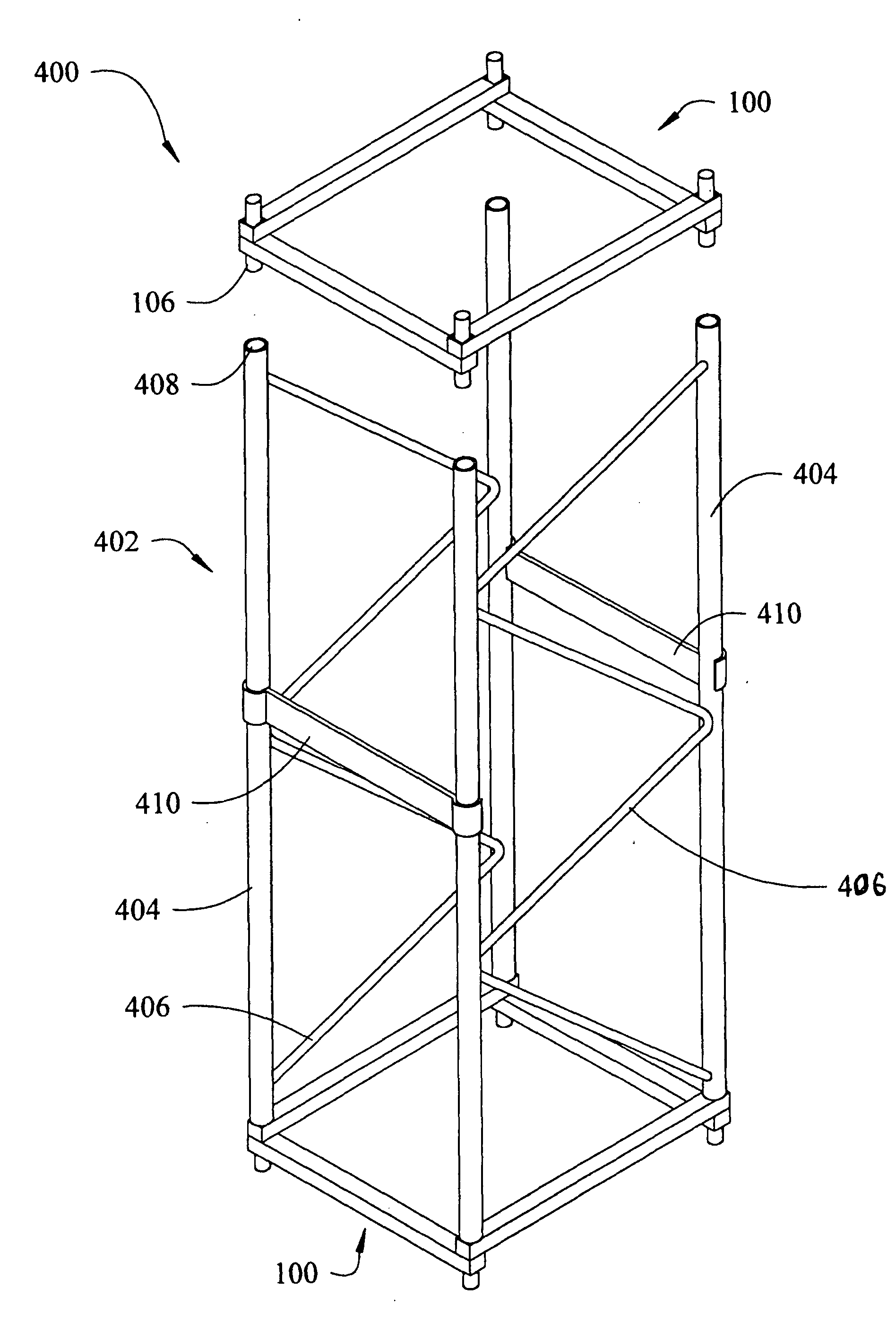

[0044] The present invention provides a portable support structure adapted for use in temporary or permanent stands or displays. The portable truss assembly is provided with a foldable end cap that connects planar wall elements.

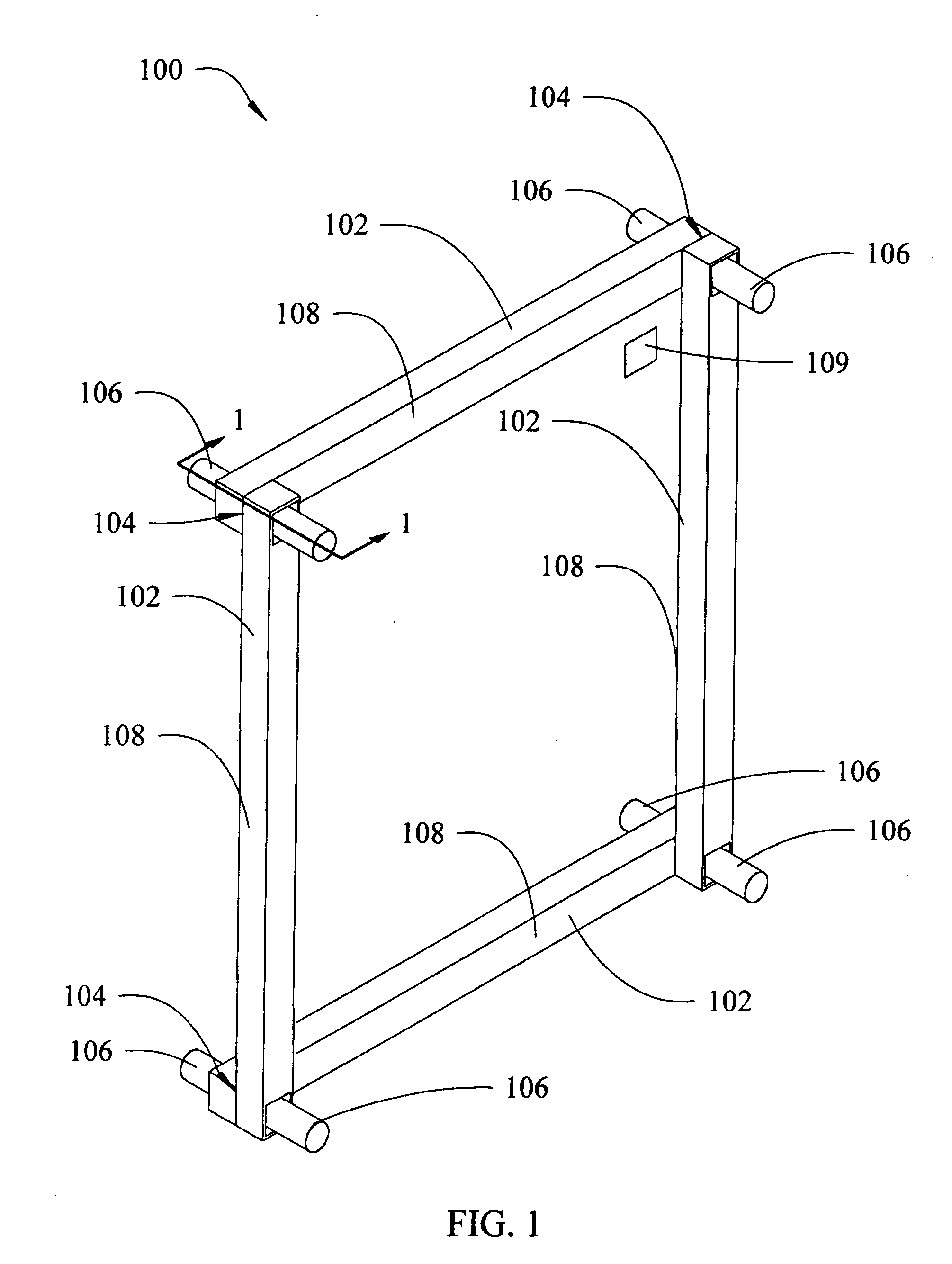

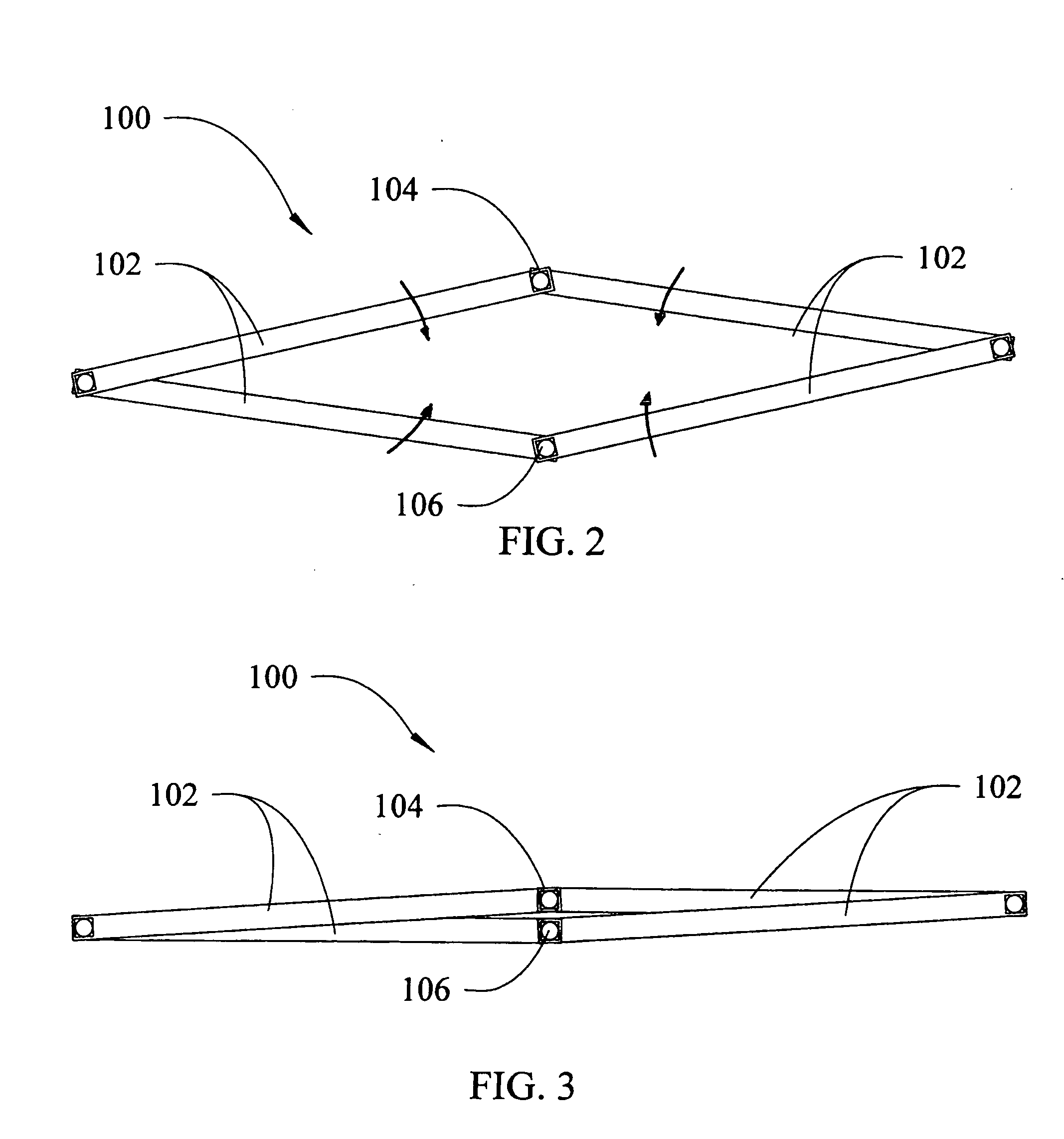

[0045]FIG. 1 illustrates a perspective view of a foldable end cap according to an embodiment of the present invention. In FIG. 1, a foldable end cap 100 includes a plurality of elongated arm members 102. The arm members 102 are adjacently connected such that a first end of a first arm member 102 is pivotally connected to a second end of a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com