Multi-component golf club head

a golf club head and multi-component technology, applied in the field of multi-material, multi-component metal wood golf club head, can solve the problems of increasing the weight of the club head, increasing the thickness of the shell, and enlarging the club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment c

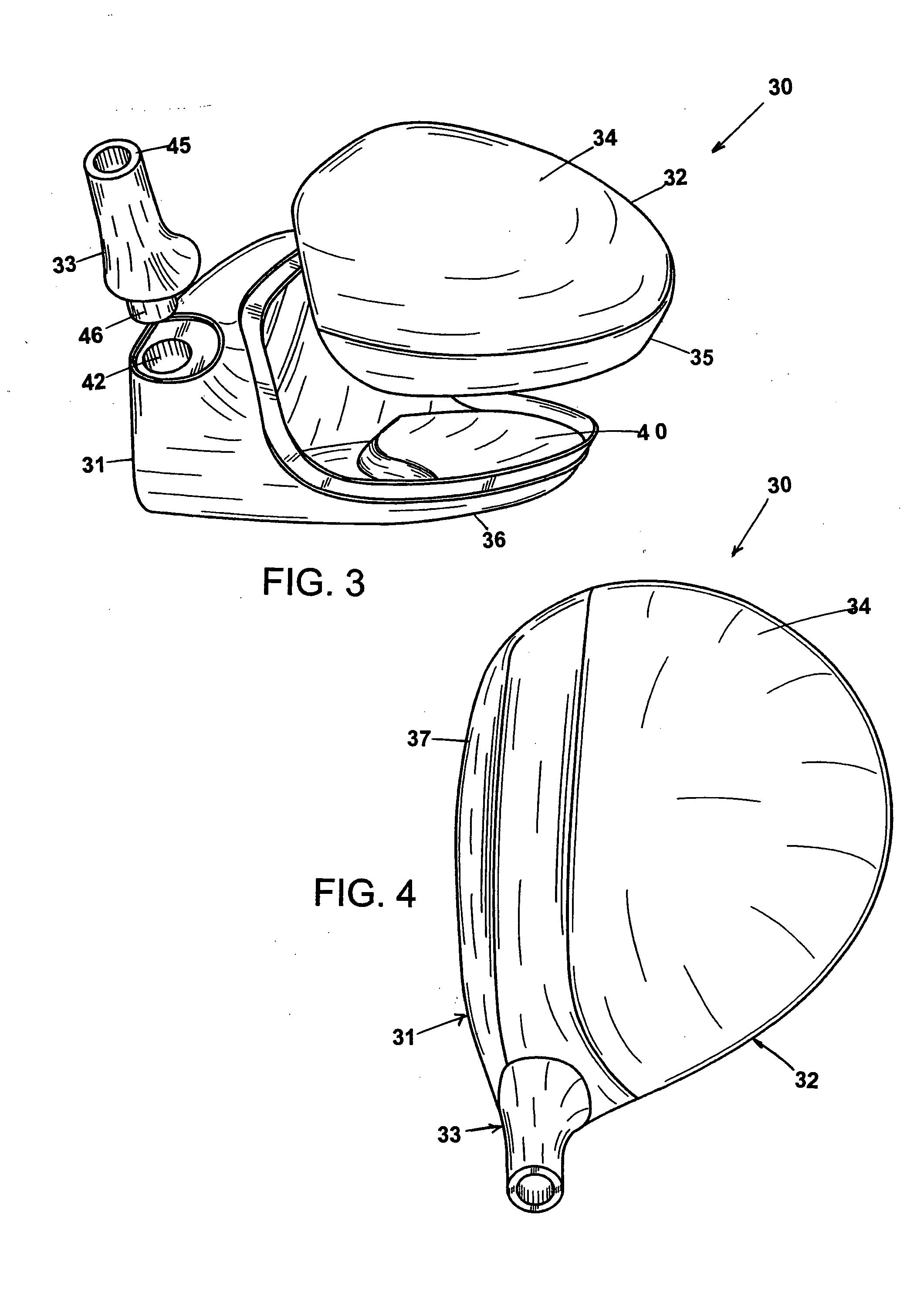

(c) Embodiment C comprises a composite second body portion 32 and a nylon hosel member 33.

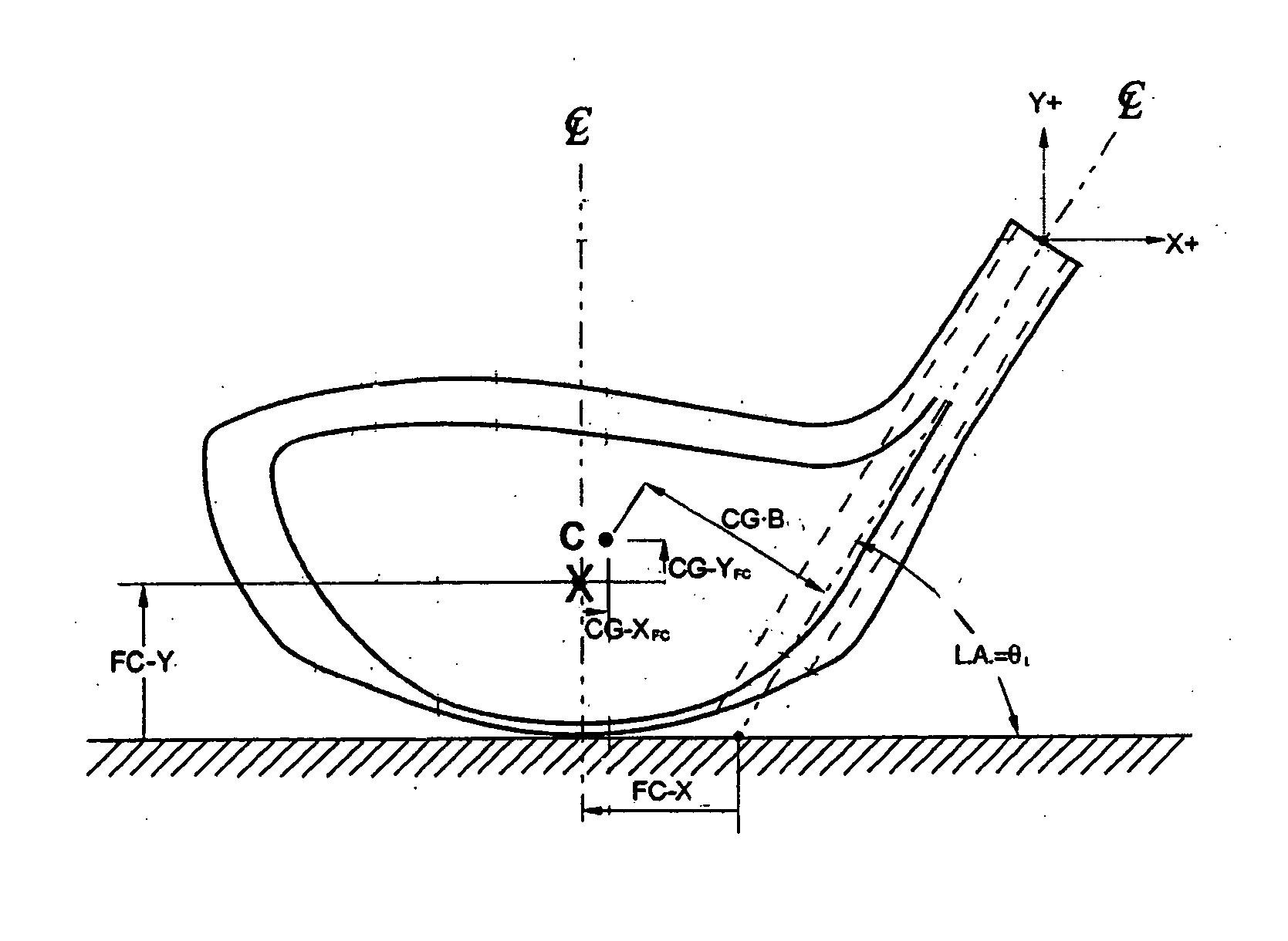

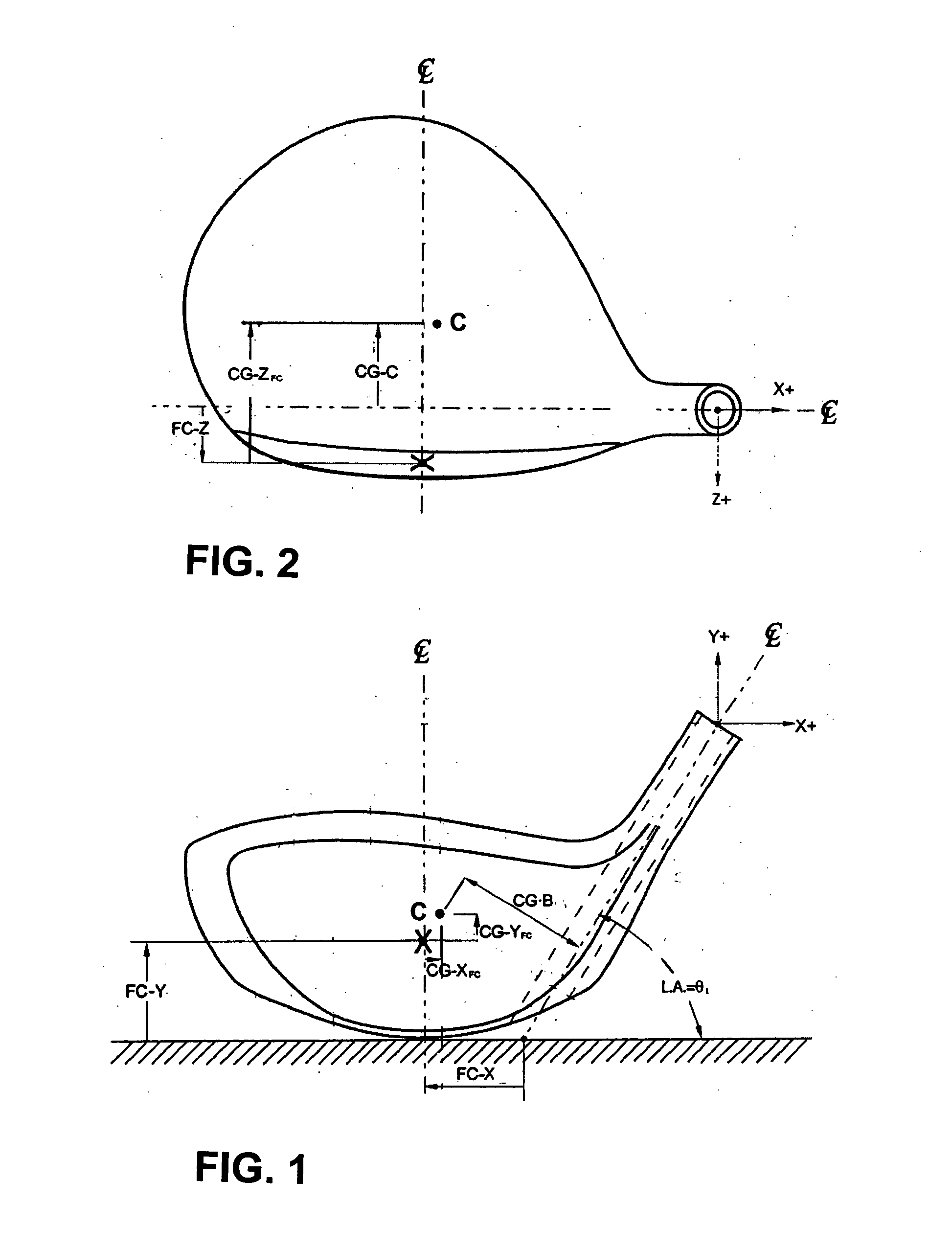

Embodiment A of the present invention provides for a shift in the center of gravity C to a position at least 6 mm below the geometric face center X. The actual test results show the center of gravity C to be 7.88 mm below its geometric face center X, while tests for the Titleist®983K (having a titanium crown and skirt) provided data indicating that the 983K's center of gravity was 2.29 mm above its geometric face center. Comparable shifts in the center of gravity C are seen in the test data for embodiments B and C.

The Titleist® 983K has a volume of 363 cubic centimeters, and a titanium SP700 stamped hitting face with a thickness of about 0.122 inch. Unlike the present invention, the 983K does not have a thickness gradient in the hitting face 48 (discussed below). And, while the second body portion 32 of the present invention is formed from magnesium, and the hosel member 33 is formed of nylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com