Method of manufacturing an optical lens

a manufacturing method and lens technology, applied in the field of customized optical lens manufacturing, can solve the problems of limited correction of blurred vision by fitting patients with lenses, affecting the optical performance of the eye, and affecting the patient's vision, etc., and achieve the effect of convenient and economical manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

” one will understand how the features of this invention provide advantages that include convenient and economical methods of manufacturing optical lens and lens blanks.

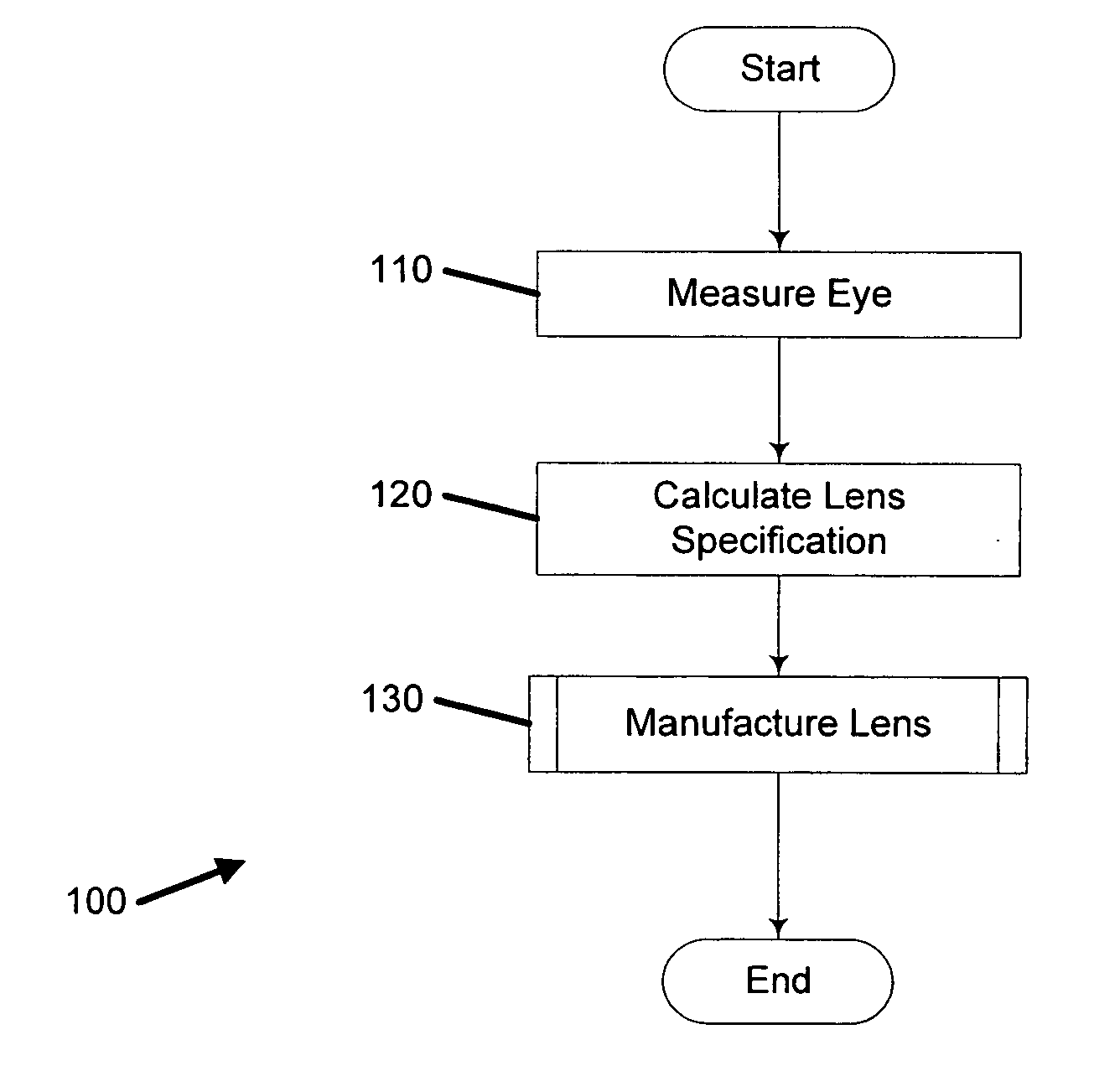

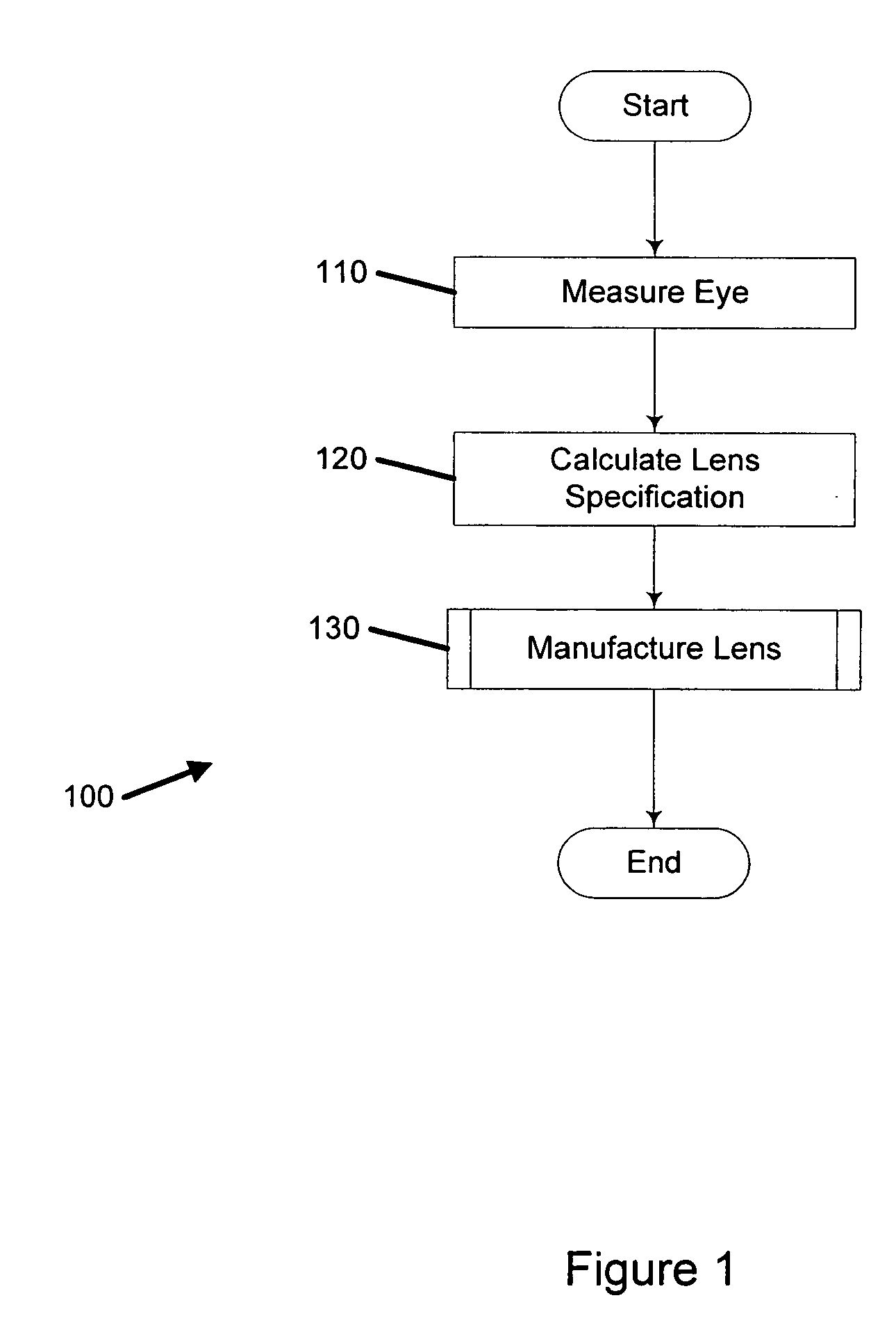

[0007] One embodiment is a method of customizing optical correction in an optical system. The method includes measuring optical aberration data of the optical system. The method further includes determining, based on the optical aberration data, a lens definition including a correction of at least one high order optical aberration. The method further includes fabricating a correcting lens based on the lens definition.

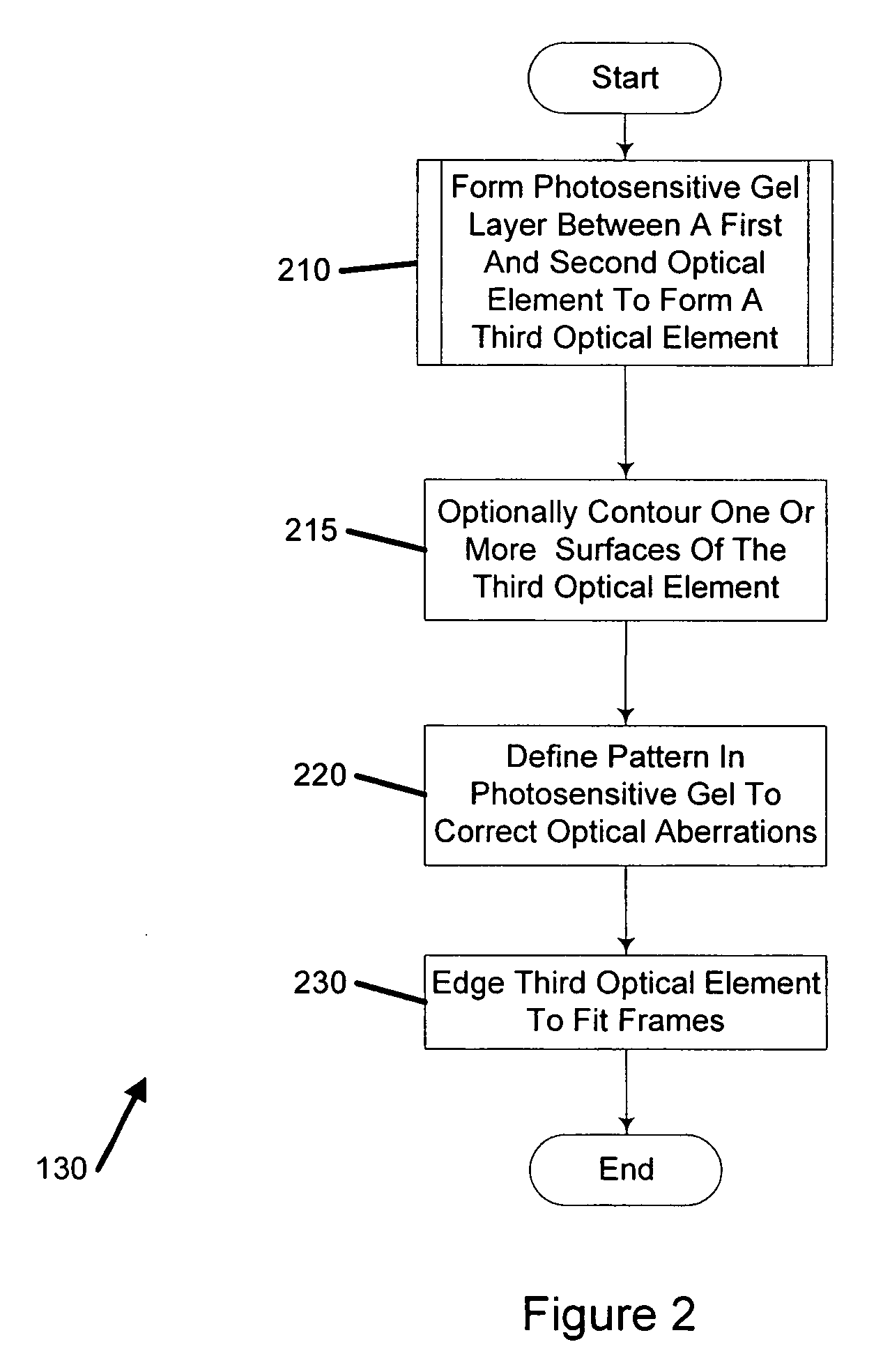

[0008] Another embodiment is a method of manufacturing a customized lens. The method includes measuring optical parameters of an optical system. The optical parameters may include measured optical aberrations. The method further includes forming a lens having at least one optical element. Forming the lens may include correcting a portion of the measured optical aberrations in the at least one optical el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com