Cleaning Tool for Floor Surfaces Having an Illumination Element for a Working Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

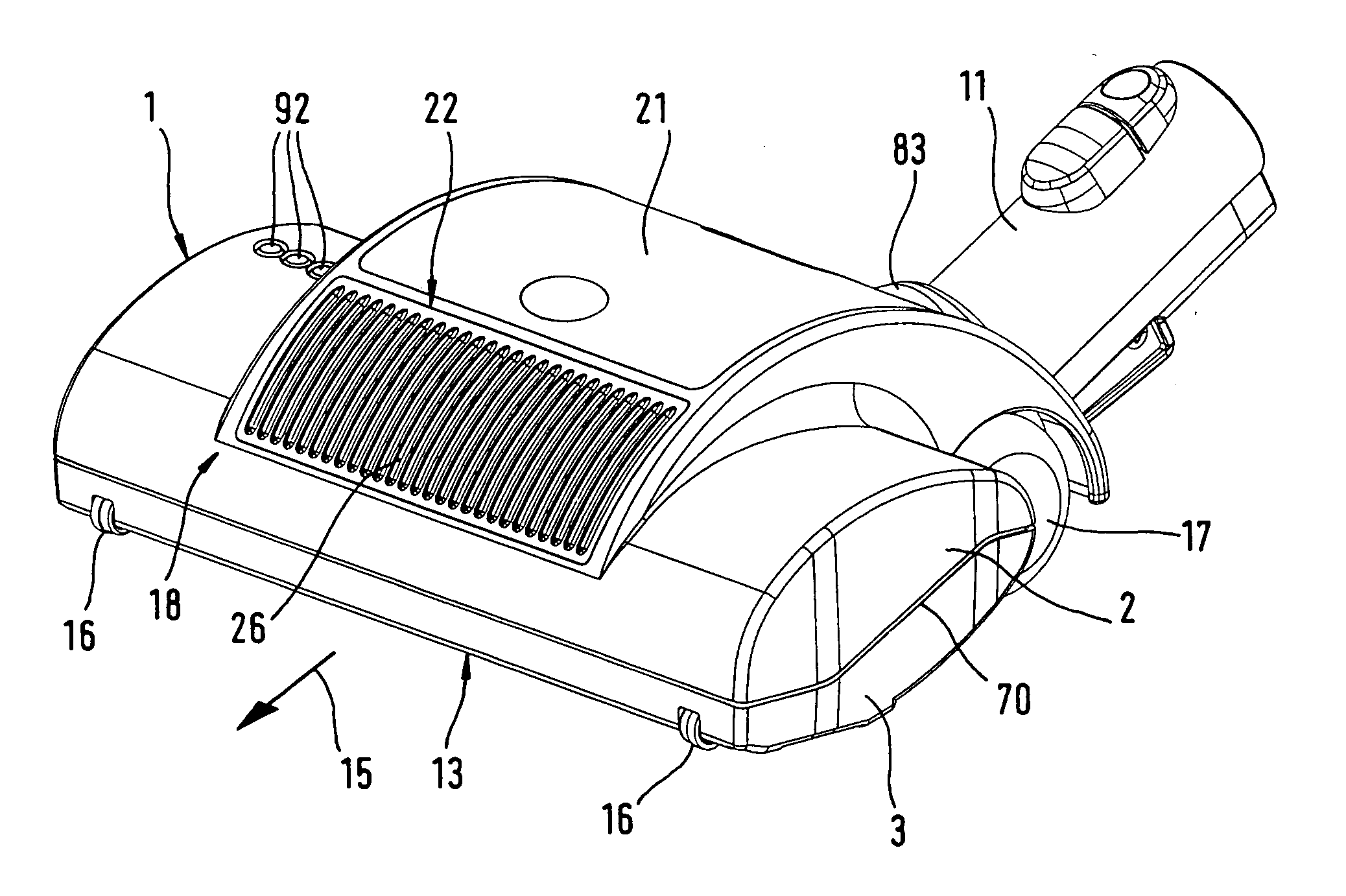

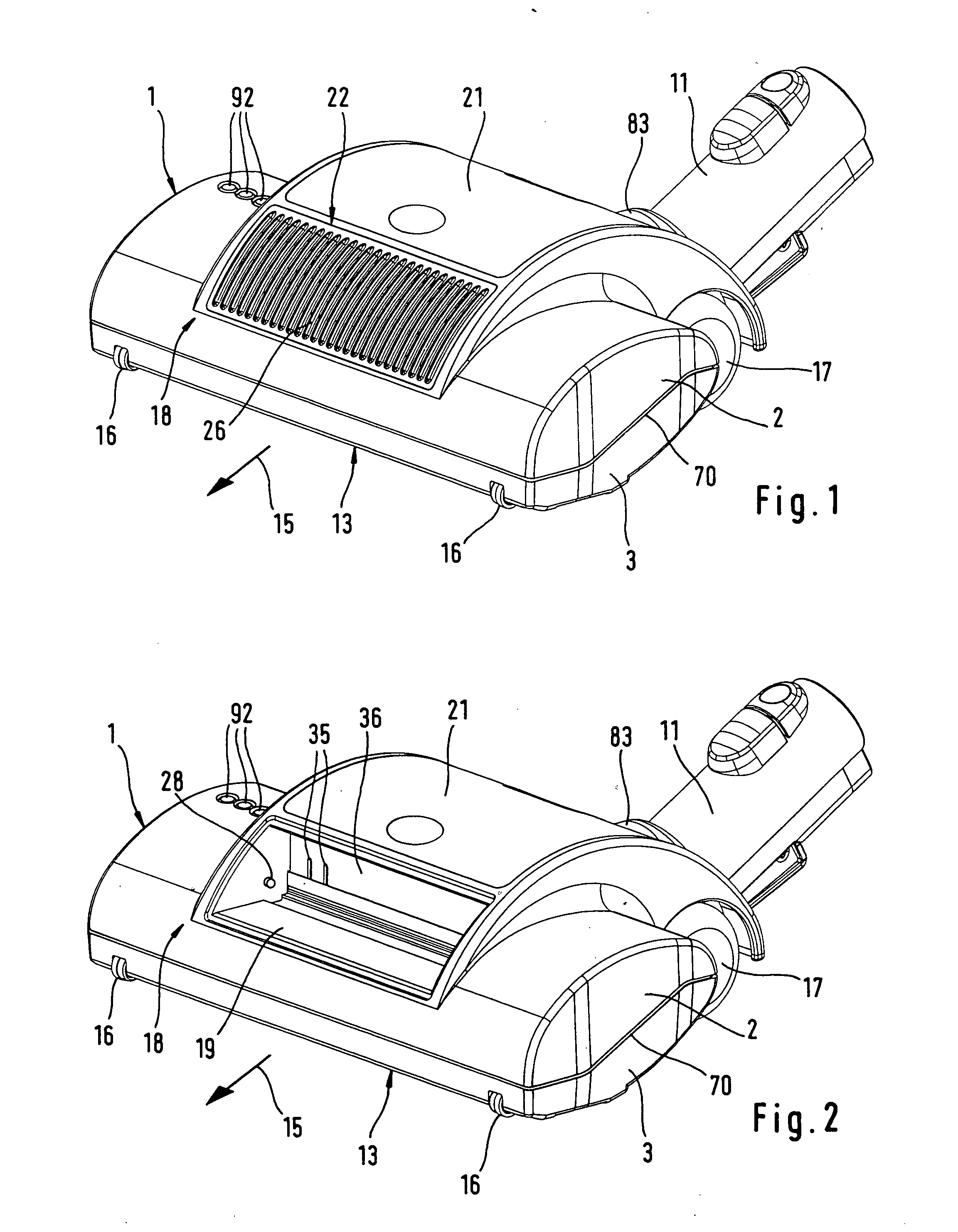

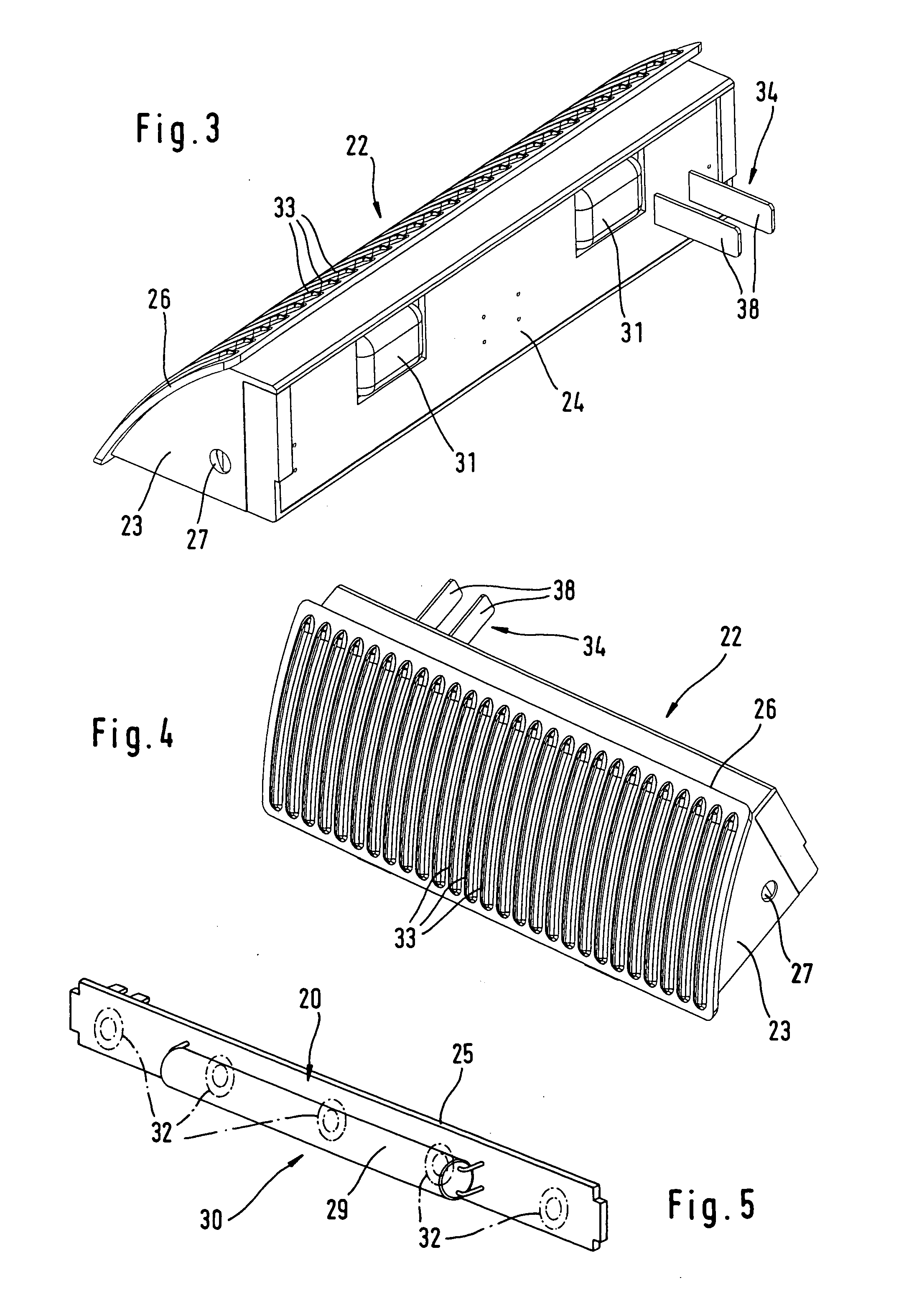

[0026] The cleaning tool for floor surfaces, upholstery surfaces or the like, as illustrated in the drawings, is configured as a vacuum cleaning tool for a vacuum cleaning device such as a vacuum cleaner. It is comprised of, as shown in FIGS. 1 and 2, of a two-part housing 1 with a top cover 2 and a bottom part 3. FIGS. 6 through 8 show that a working chamber 4 is provided in the housing 1 and a brush roller 5 is arranged in the working chamber 4 and driven so as to rotate about an axis of rotation 6. The drive action is realized by a belt drive 7 that, in the illustrated embodiment, is driven by a drive motor 8. The drive motor 8 is part of a drive unit 9 that can be inserted as a module into the motor chamber 10 of the housing 1. The motor chamber 10 is separated from the working chamber 4 wherein the working chamber 4 in the illustrated embodiment is connected by a vacuum connector 11 to a vacuum cleaning device. The connection between the working chamber 4 and the vacuum connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com