Non-resiliency body-contact protective helmet interface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

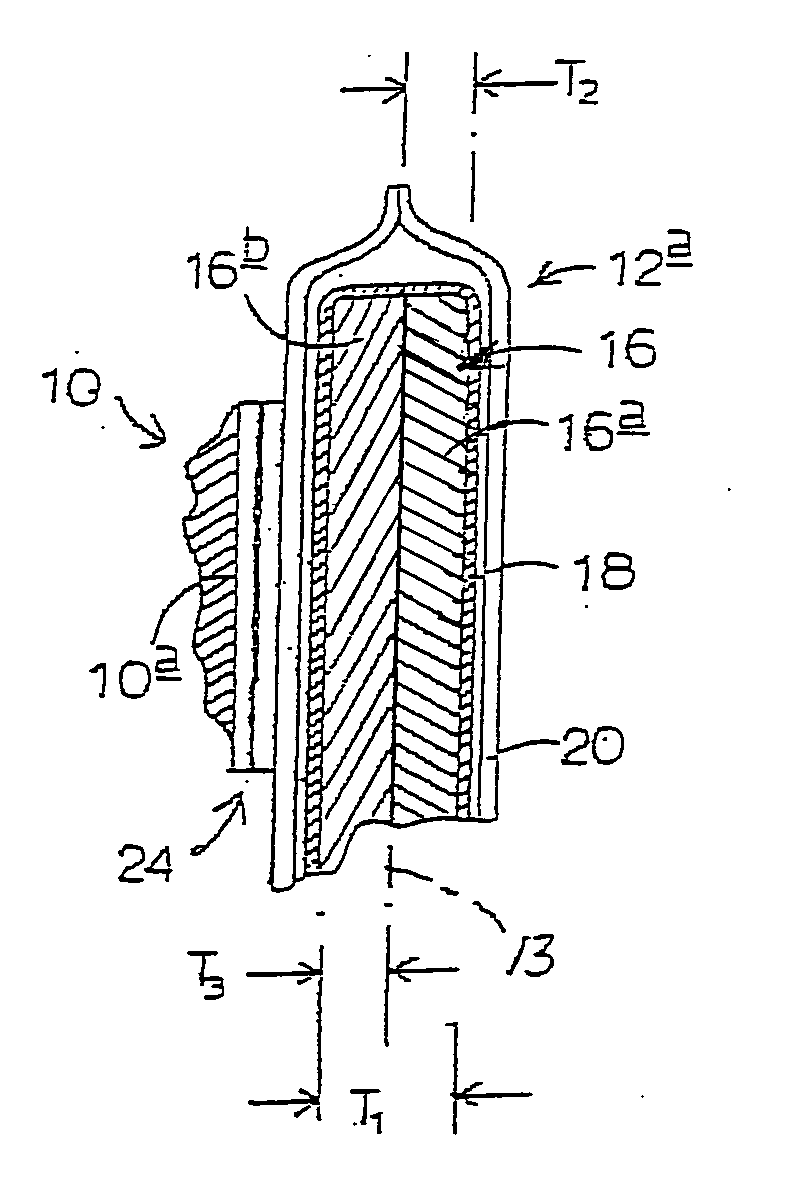

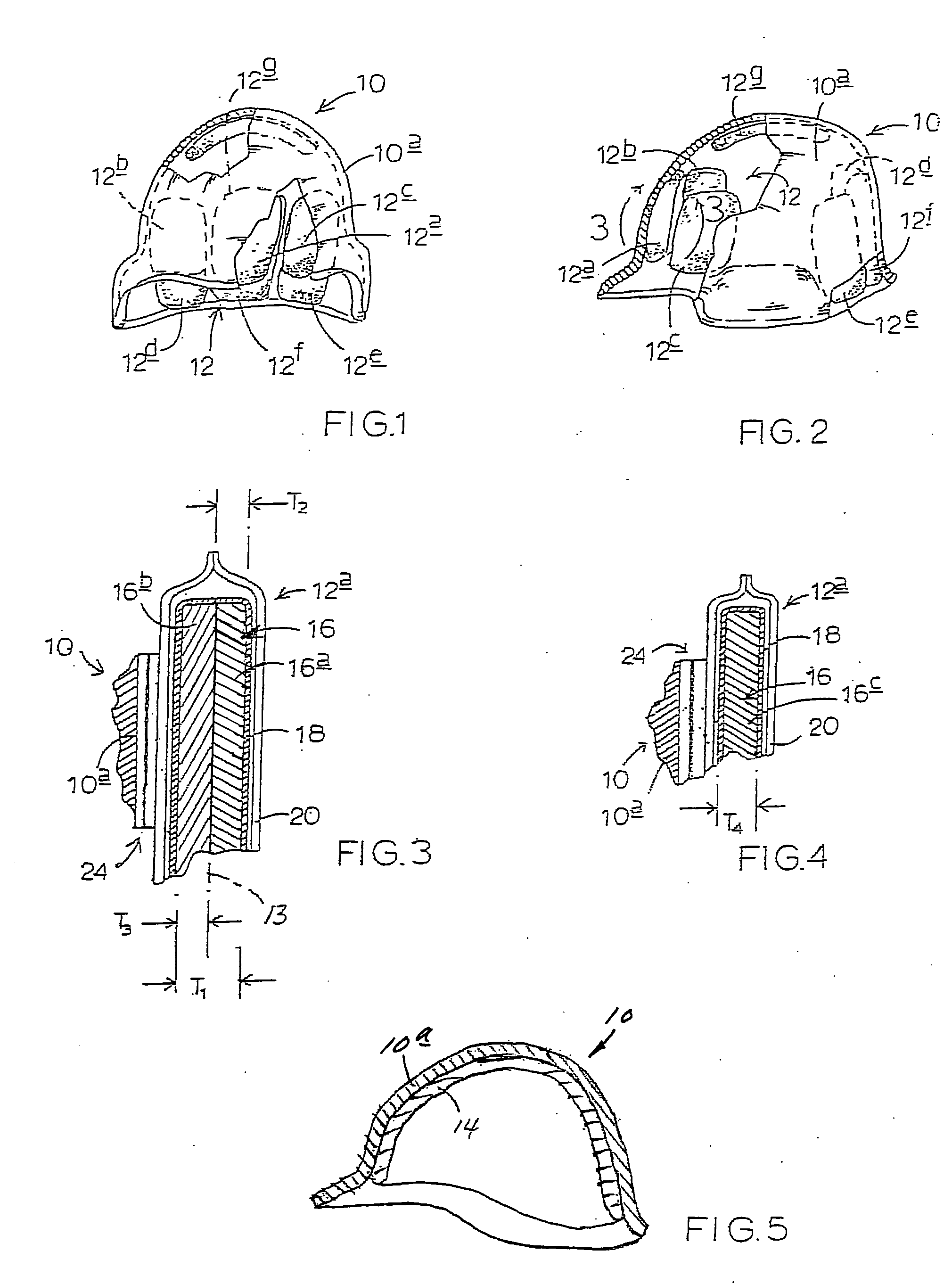

[0020] Turning attention now to FIGS. 1, 2 and 3, indicated generally at 10 (FIGS. 1 and 2) is a military helmet including a shell 10a. In all respects, shell 10a is completely conventional in construction, and might have any one of a number of different specific constructions and configurations.

[0021] Fastened in one of a variety of appropriate manners on the inside, concave, dome-like surface of shell 10a is an installation 12 of shock-absorbing, load-cushioning interface structure constructed in accordance with the present invention. Installation 12, in the particular setting illustrated in these figures and now being described, includes seven, individual, multi-layer, load-cushioning, interface-structure pads 12a, 12b, 12c 12d, 12e, 12f, 12g, each of which includes one preferred form of a central, or core, load-cushioning instrumentality possessing certain characteristics which are key to the structure and functionality of the present invention. Pad 12a is joined to the inside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com