Self-propelling cleaner

a self-propelling cleaner and cleaner technology, applied in the direction of cleaning filter means, cleaning action control, electric equipment installation, etc., can solve the problems of conventional self-propelling cleaners, suction is not taken in sufficient safety measures, and the self-propelling cleaner may collide, so as to reduce the impact of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A self-propelling cleaner according to an embodiment of the present invention will be hereinafter described.

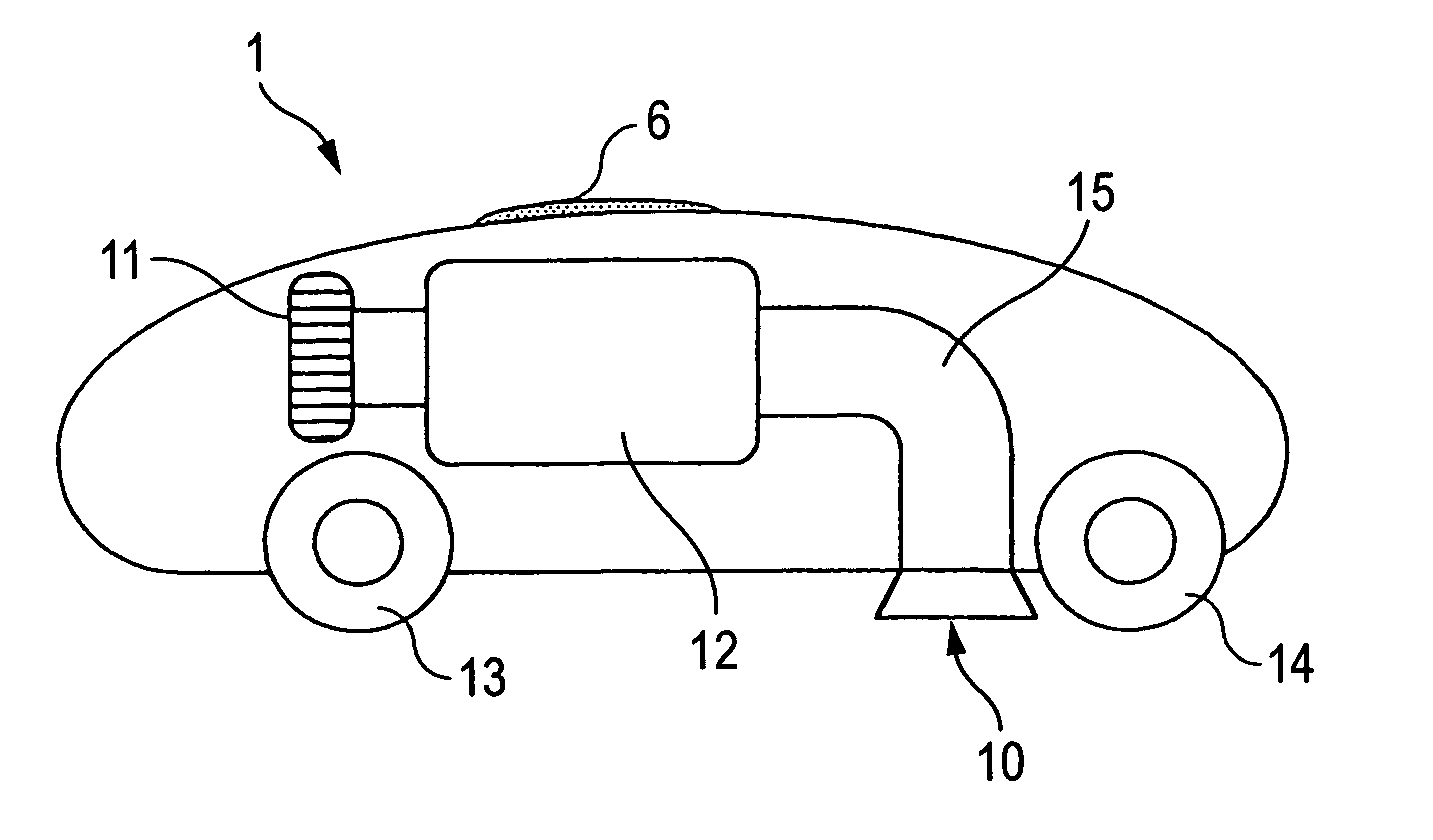

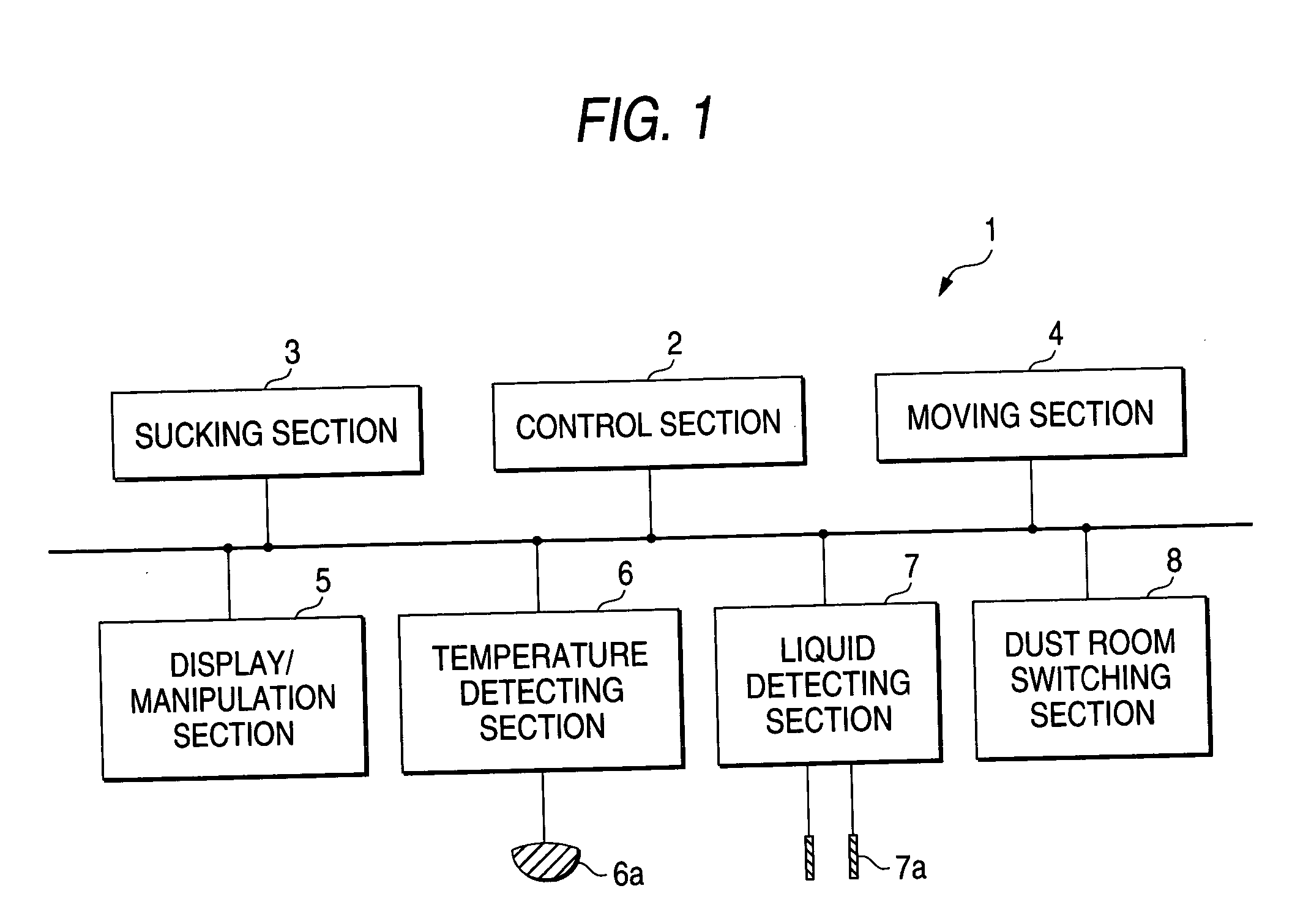

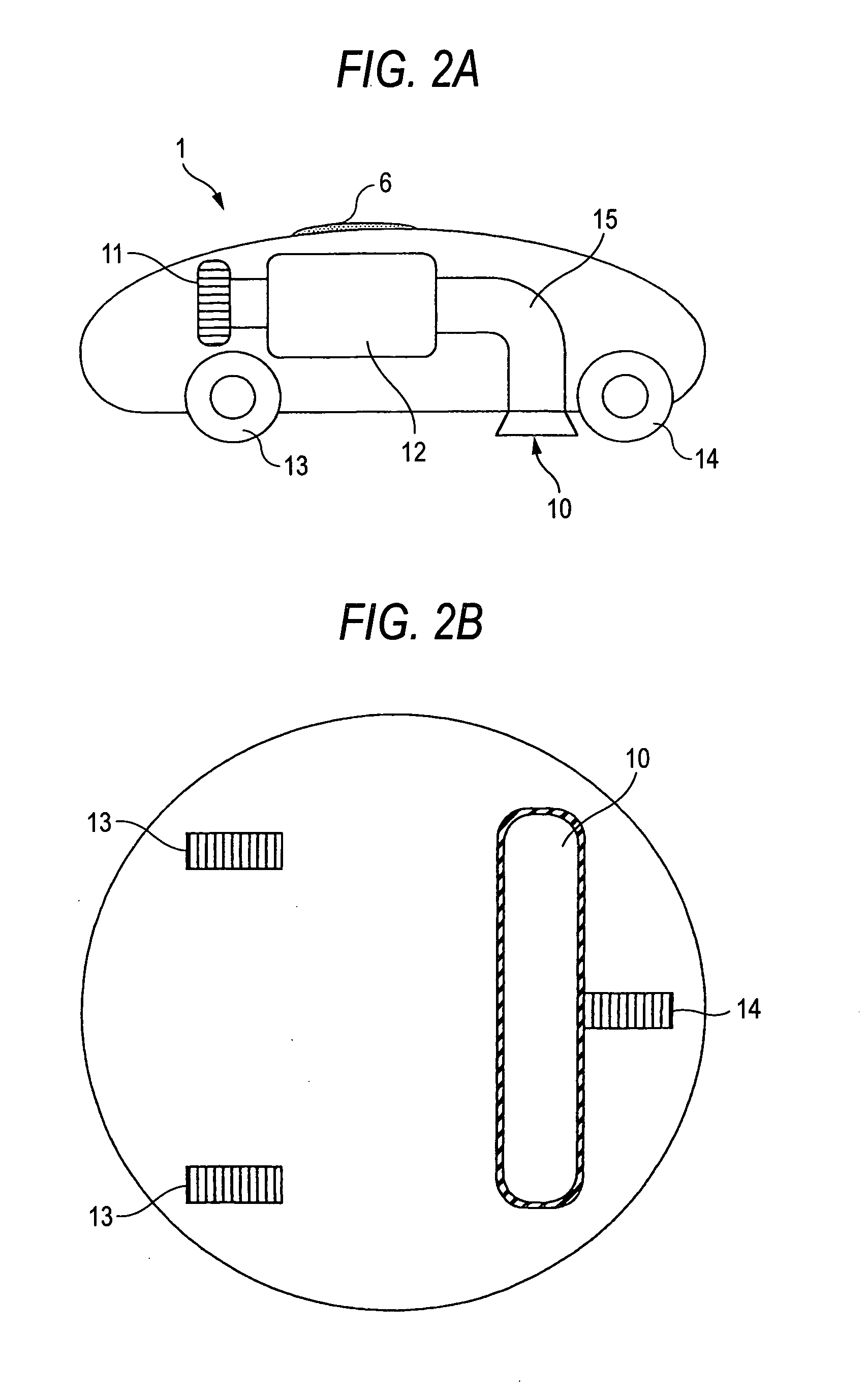

[0017]FIG. 1 is a block diagram showing the configuration of the main part of the self-propelling cleaner according to the embodiment of the invention. FIGS. 2A and 2B are schematic diagrams showing the internal structure of the self-propelling cleaner according to the embodiment. FIG. 2A is a side sectional view and FIG. 2B is a bottom view. The self-propelling cleaner 1 according to the embodiment is equipped with a control section 2 for controlling the operation of the main body, a sucking section 3 for sucking dust into the main body, a moving section 3 for causing the main body to move autonomously, a display / manipulation section 5 for displaying the status of the main body and receiving a manipulation input to the main body, a temperature detecting section 6 for judging whether the temperature of an object that has been sucked into the main body is higher than a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com