Vacuum online feeding device of positive pressure system

A technology of feeding device and vacuum generating device, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve problems such as material clogging, achieve the effects of avoiding clogging failure, economical and practical, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

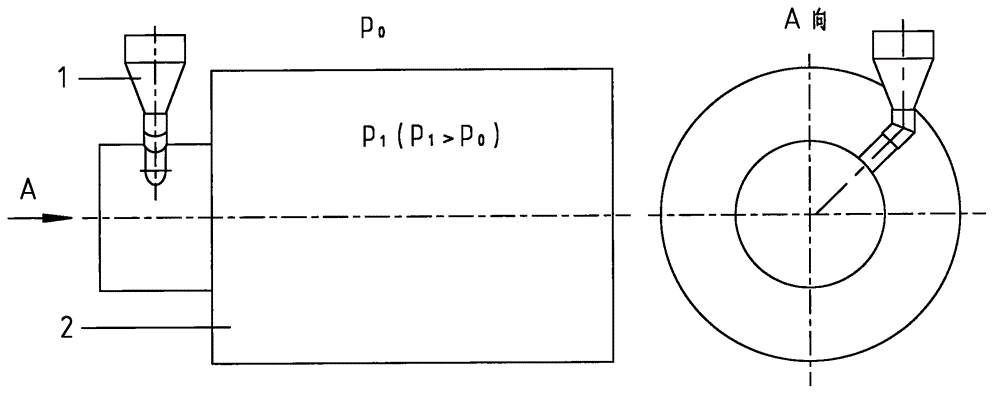

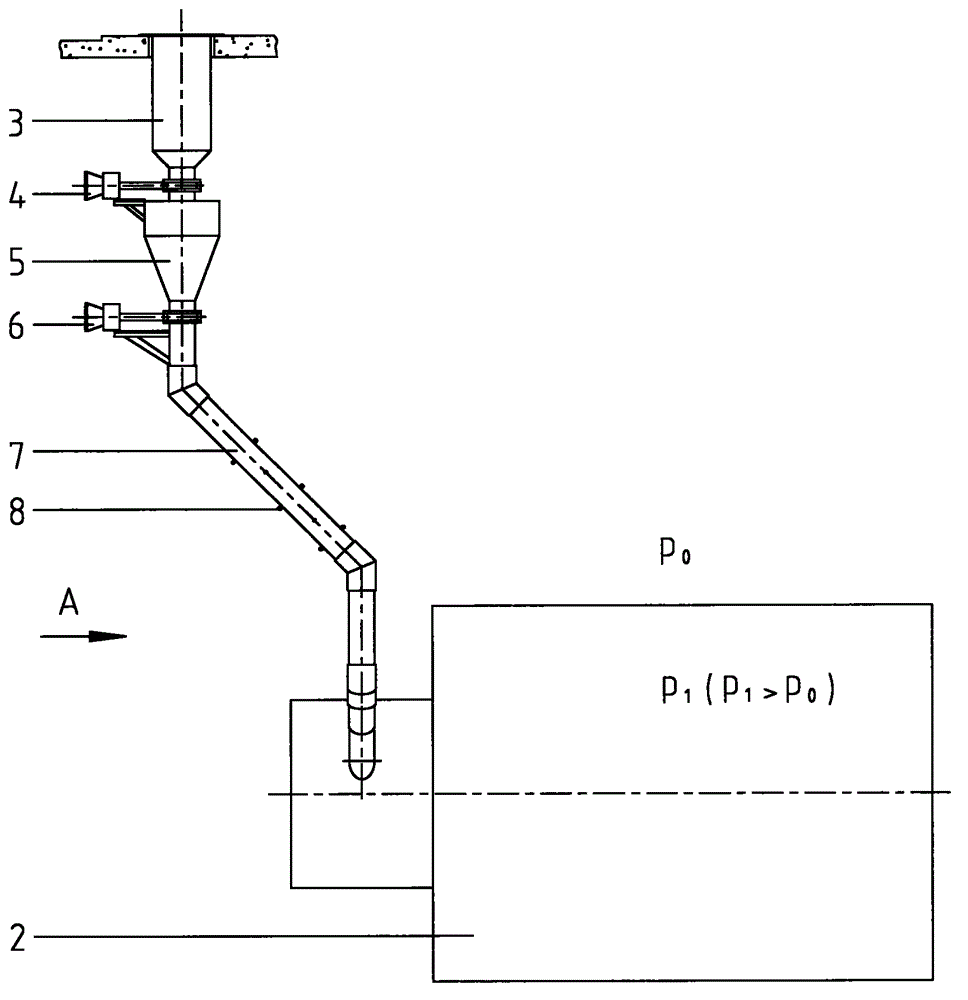

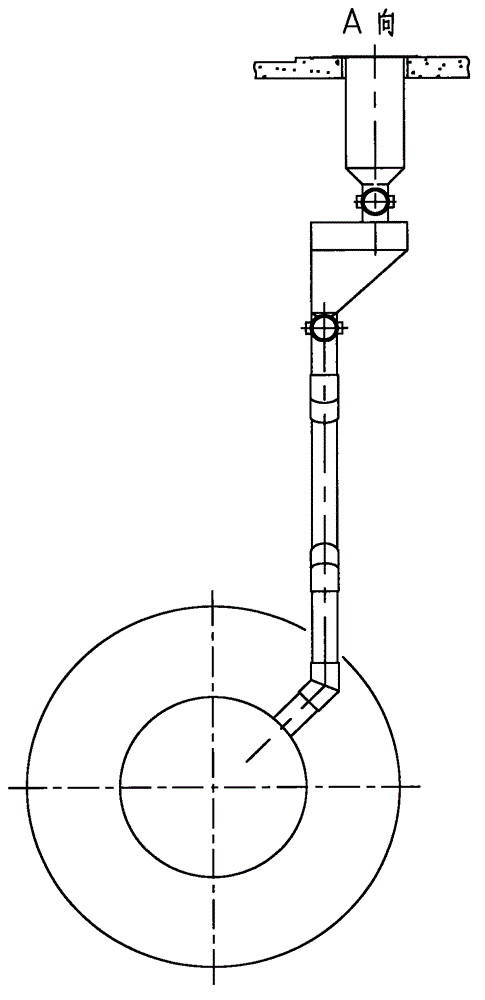

[0023] Figure 4 , Figure 5 It is a structural schematic diagram of a positive pressure system vacuum online feeding device provided by the present invention. The conical feed hopper 9 and the vacuum generating device 11 in the positive pressure system vacuum online feeding device are connected to the electric valve 10 through a flange, and the material The buffer device 12 is welded at the material outlet of the long tube 14 of the vacuum generating device 11; Image 6 , Figure 7 , Figure 8 It is a structural schematic diagram of the vacuum generating device 11. The long tube 14 in the vacuum generating device 11 is composed of a section of vertical tube and a section of inclined tube, and the two tubes form an included angle of 45°. Two left air inlet pipes 12 and right air inlet pipes 13 of the same smaller diameter are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com