Skirted closure for small dropper bottles

a dropper bottle and closure technology, applied in the field of closure devices, can solve the problems of contaminants entering the nozzle and the nozzle aperture area, and none of the devices have addressed the contamination problem,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

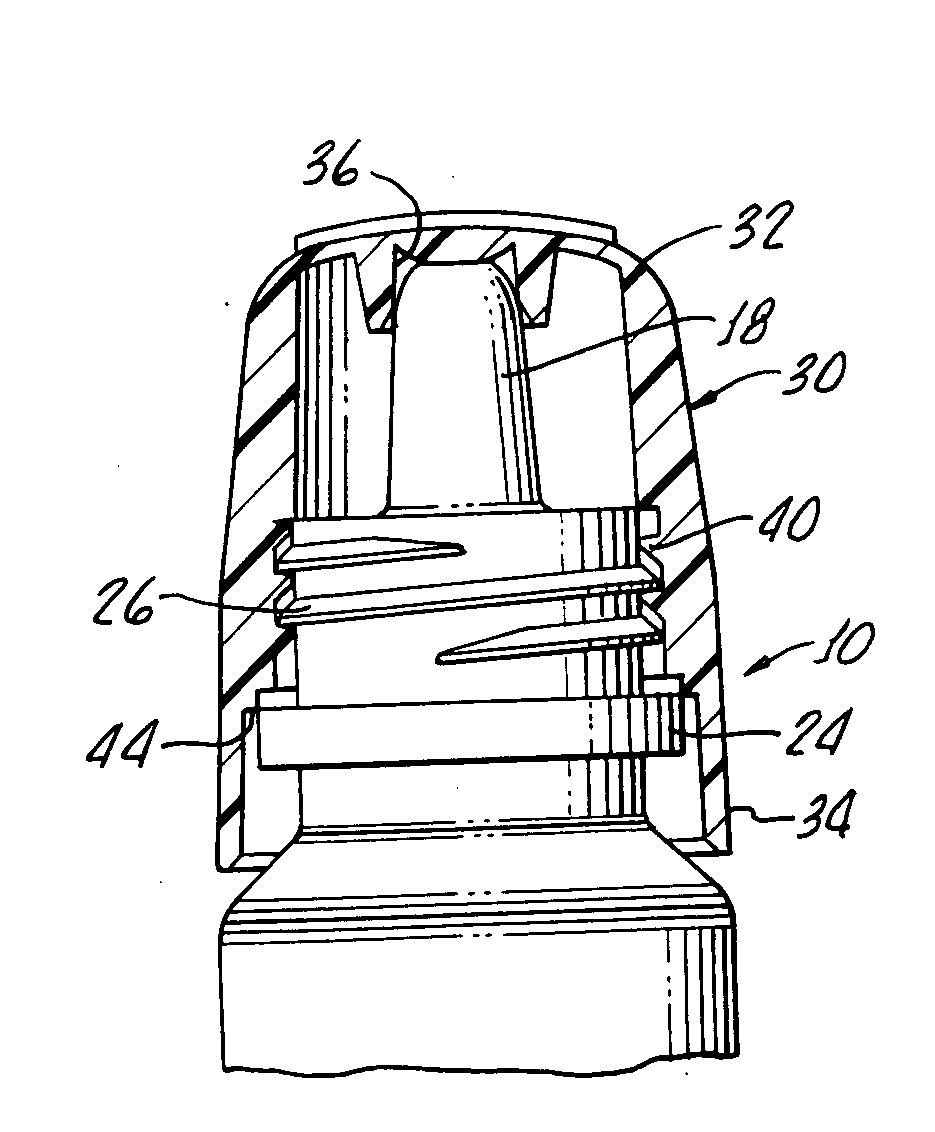

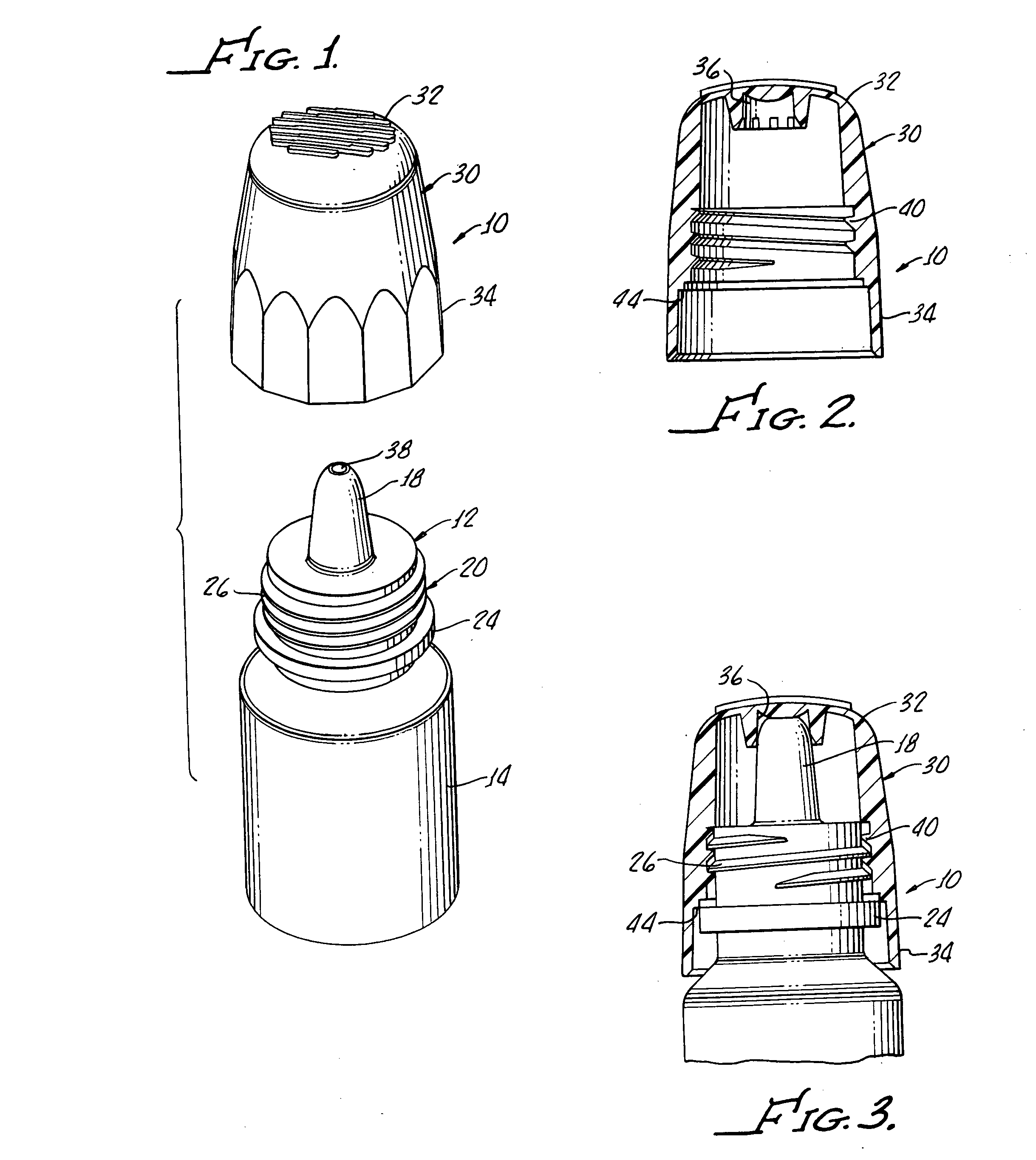

[0015] With reference to FIGS. 1-3, there is shown a closure 10 in accordance with the present invention which generally includes a nozzle 12 disposed on a bottle 14 and having a neck 18 and a shoulder 20. The nozzle 12 may be inserted into the bottle 14 or otherwise formed therein.

[0016] The closure 10 may be formed from any suitable injection multiple polymer preferably polypropylene. The closure 10 is most suitable for small bottles having a capacity of less than about 8 ml which necessitates small closure 10. Such small closures makes removal of the cap difficult especially where the primary user may be elderly or with limited hand mobility. This is further a concern for dropper bottles where the elderly are the primary users.

[0017] As hereinafter described in greater detail, the shoulder 20 includes a circumferential ring 24 and threads 26 disposed between the ring 24 and the neck 18.

[0018] The closure 10 further includes a cap 30 having a top 32 and an axially downwardly ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com