Guided power tool and method for operating a guided power tool

a power tool and guided technology, applied in the direction of portable power tools, manufacturing tools, portable drilling machines, etc., can solve problems such as machining problems, and achieve the effects of avoiding damage to the workpiece and/or an object embedded in it, improving operating comfort, and good work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

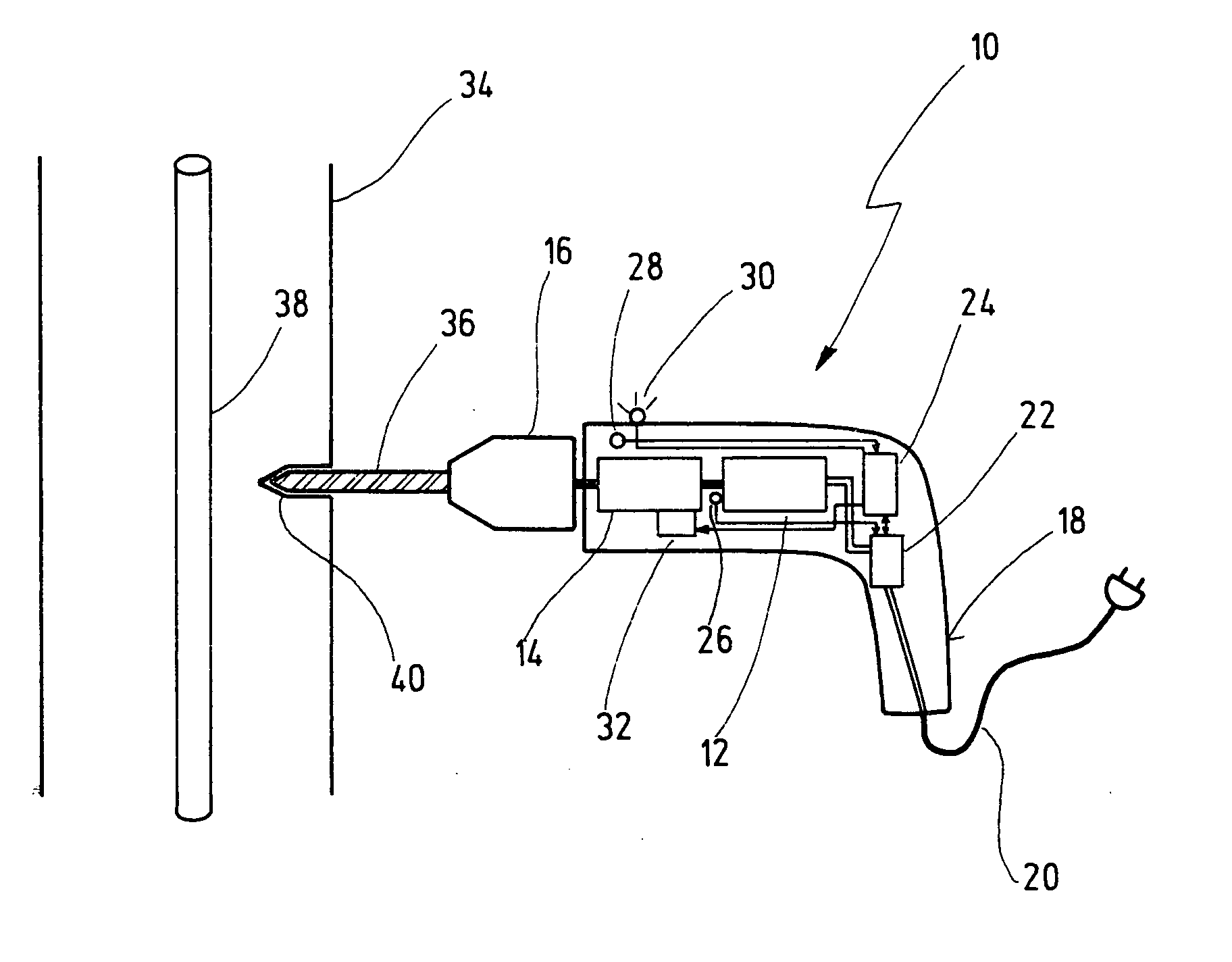

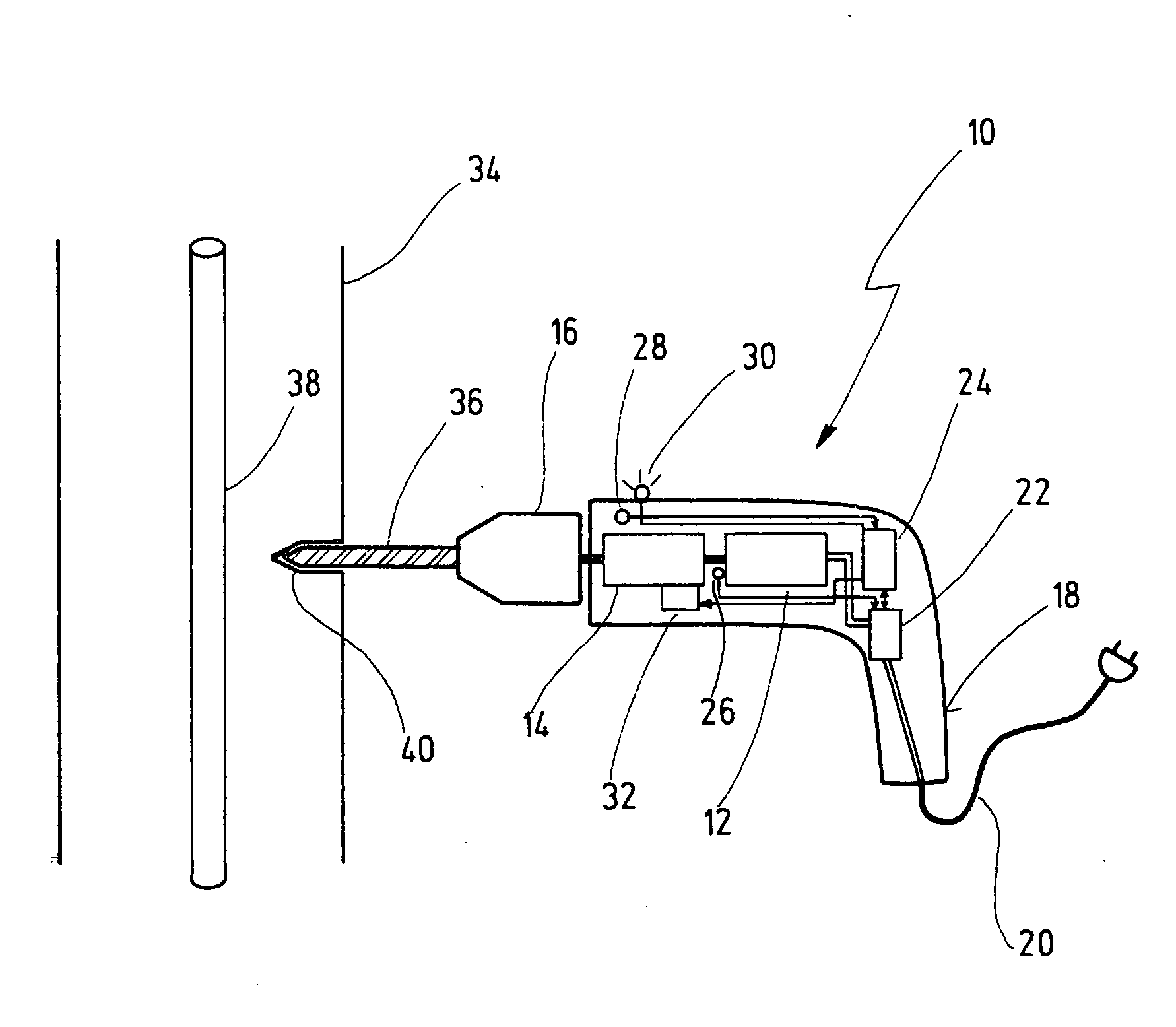

[0015] A preferred hand-guided power tool 10 is composed of a drive motor 12 located in a housing 18, the drive motor driving an insert tool 36 configured as a drill bit and retained in a detachable manner in a tool holder 16, and is further composed of a motor electronic unit 22 for controlling drive motor 12, and a striking mechanism 14. In the exemplary embodiment, striking mechanism 14 is equipped with a striking mechanism control 32, whereby striking mechanism 14 is drivable by drive motor 12, so that insert tool 36 can be driven in a percussive or rotating manner, with or without percussion. Separate drive units can also be provided for striking mechanism 14 and insert tool 36. Drive motor 12 is supplied with current via an electrical connecting cable 20. A rechargeable operating means can also be provided, as an option. A speed sensor 26 is provided on drive motor 12 to detect the rotational speed of drive motor 12.

[0016] With insert tool 36 configured as a drill, a hole 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical voltage | aaaaa | aaaaa |

| rotational speed | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com