Offset eyeglasses clasp

a technology of eyeglasses and clasps, applied in the field of eyeglasses, can solve the problems of metal clips weakening, metal clips falling out, and/or getting damaged, and achieve the effect of reducing the wear of the magn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

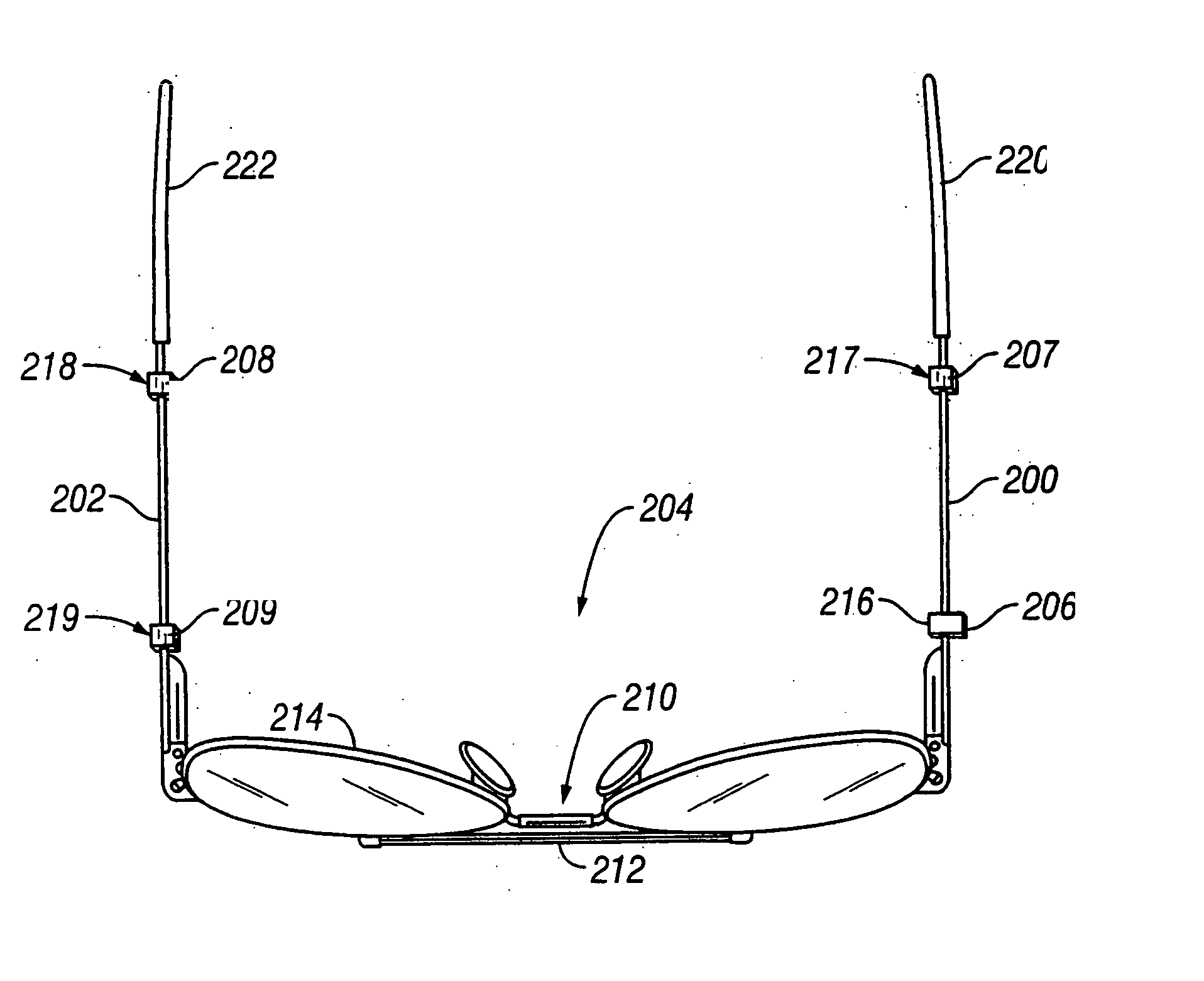

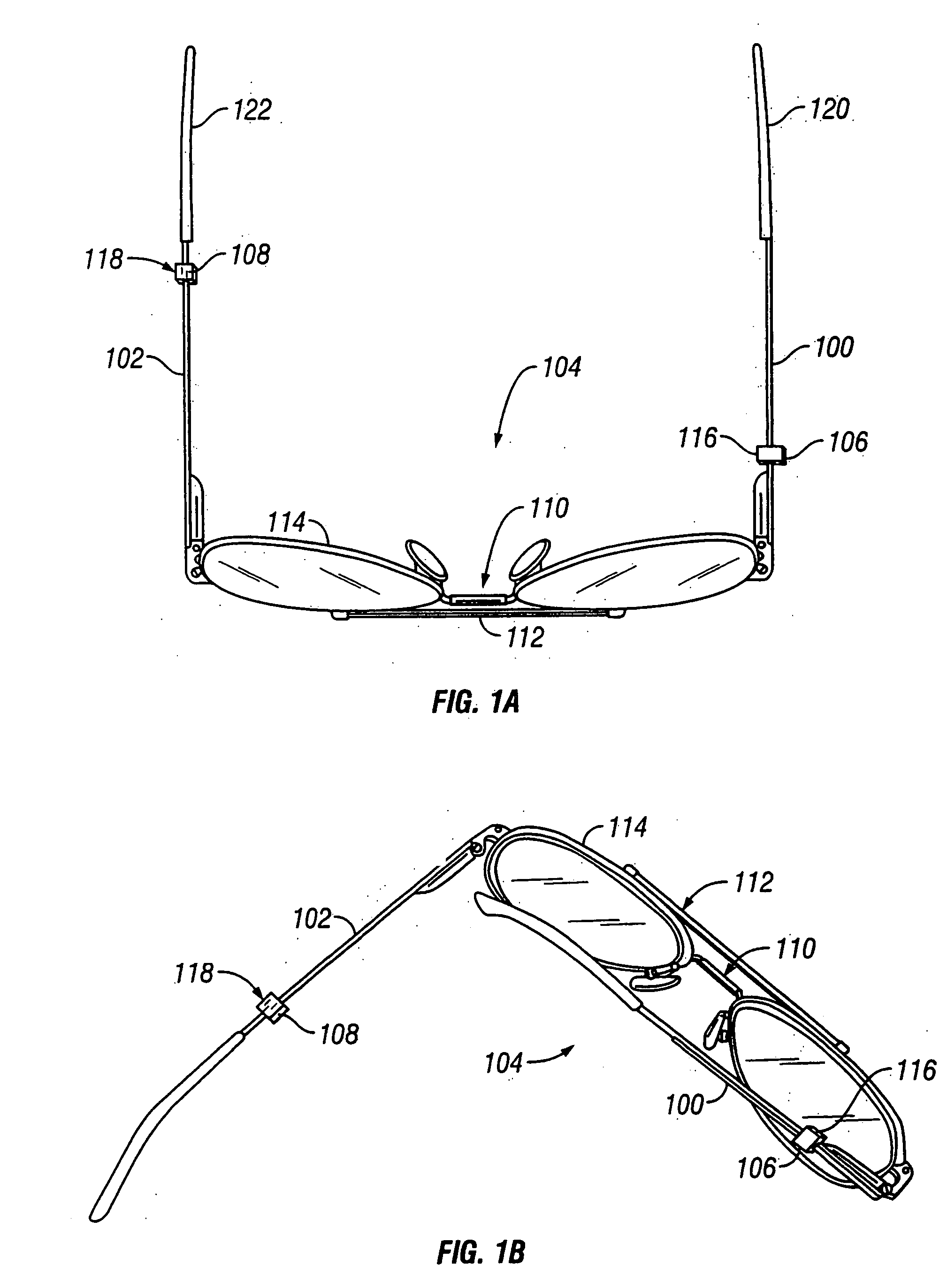

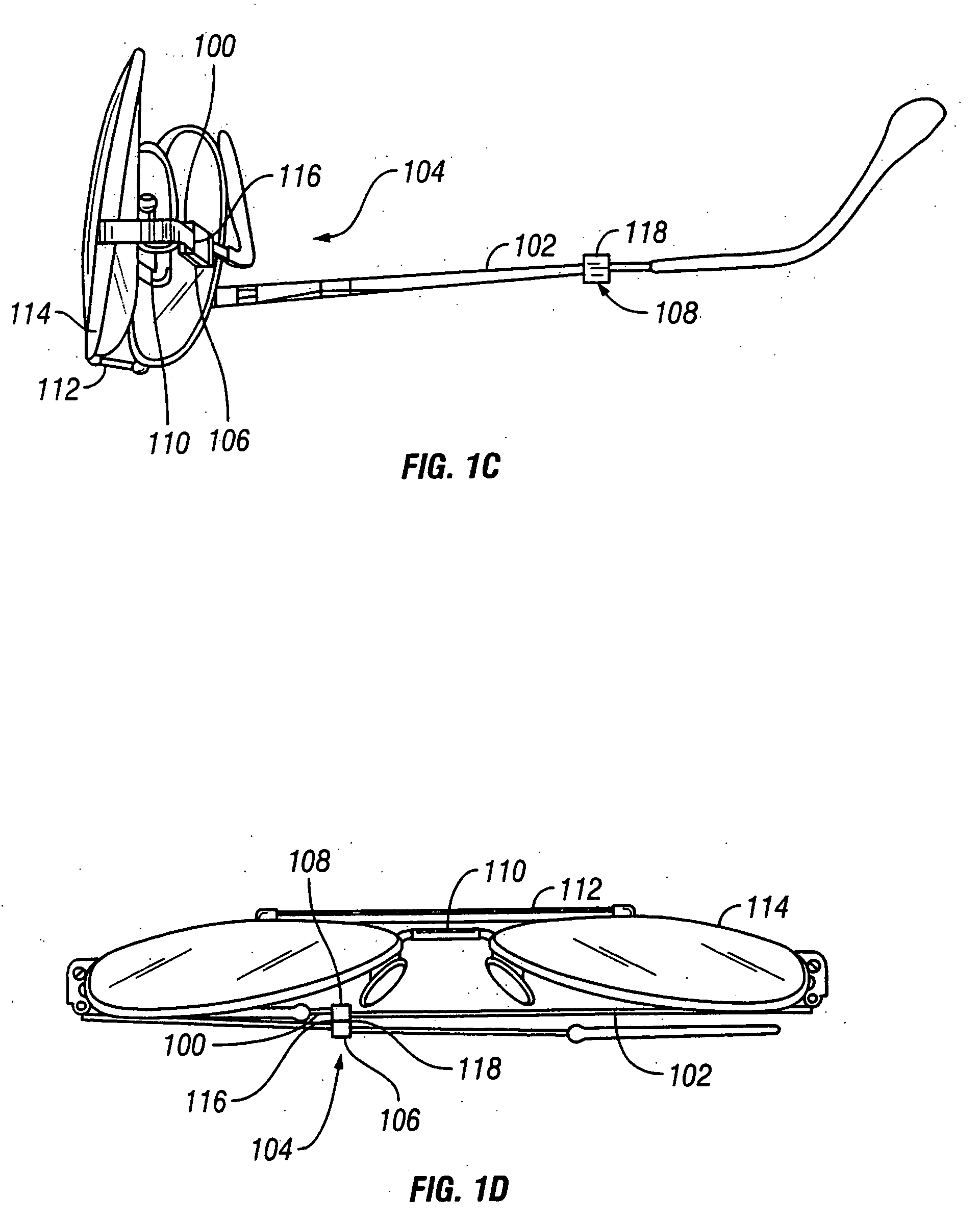

Image

Examples

example 1

[0052] The 4-magnet embodiment in FIGS. 4A-4E wherein the magnets 400, 402, 404, 406 are MGO grade 35 Neodymium (Nd—Fe—B) disks 0.25″ diameter and 0.1″ thick The shrink-wrap tubing has an OD of 0.350″ before shrinking, a wall thickness of 0.020″, and is parallel to the temple bars 308, 310. The magnets 400, 402, 404, 406 exhibit a field of 4 kG and require a load of 400 gm for un-clasping.

example 2

[0053] The 4-magnet embodiment in FIGS. 4A-4E wherein the magnets 400, 402, 404, 406 are MGO grade 35 Neodymium disks 0.25″ diameter and 0.1″ thick. The shrink-wrap tubing has an OD of 0.350″ before shrinking, a wall thickness of 0.010″, and is perpendicular to the temple bars 408, 410. The magnets exhibit a field of 6 kG and require a load of 600 gm for un-clasping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com