Gloves with reinforcing elements and methods for making same

a technology of reinforcing elements and gloves, applied in the field of gloves, can solve the problems of increased total manufacturing cost of gloves, increased final retail price paid by consumers, and discomfort and potential irritation of hands of people wearing gloves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

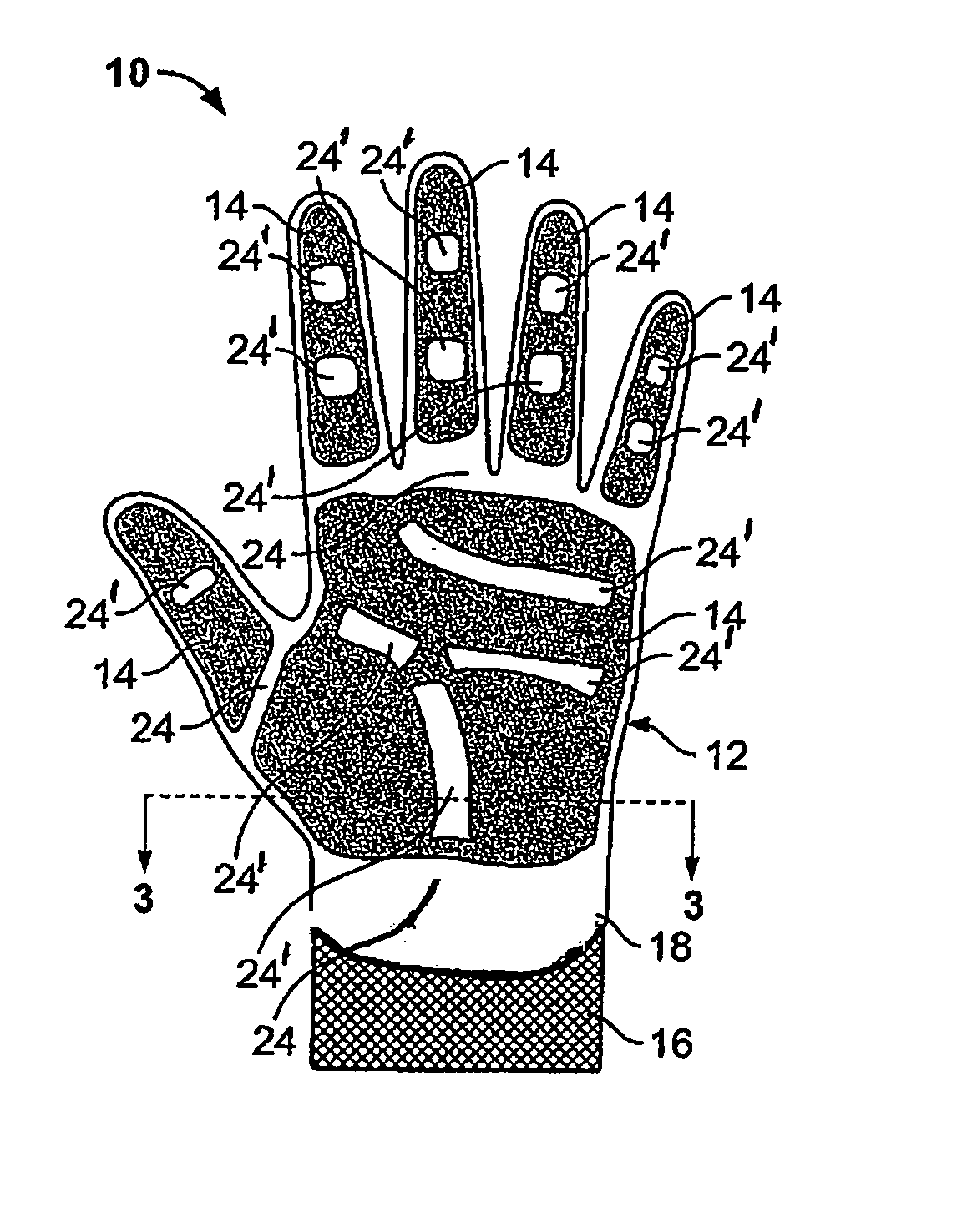

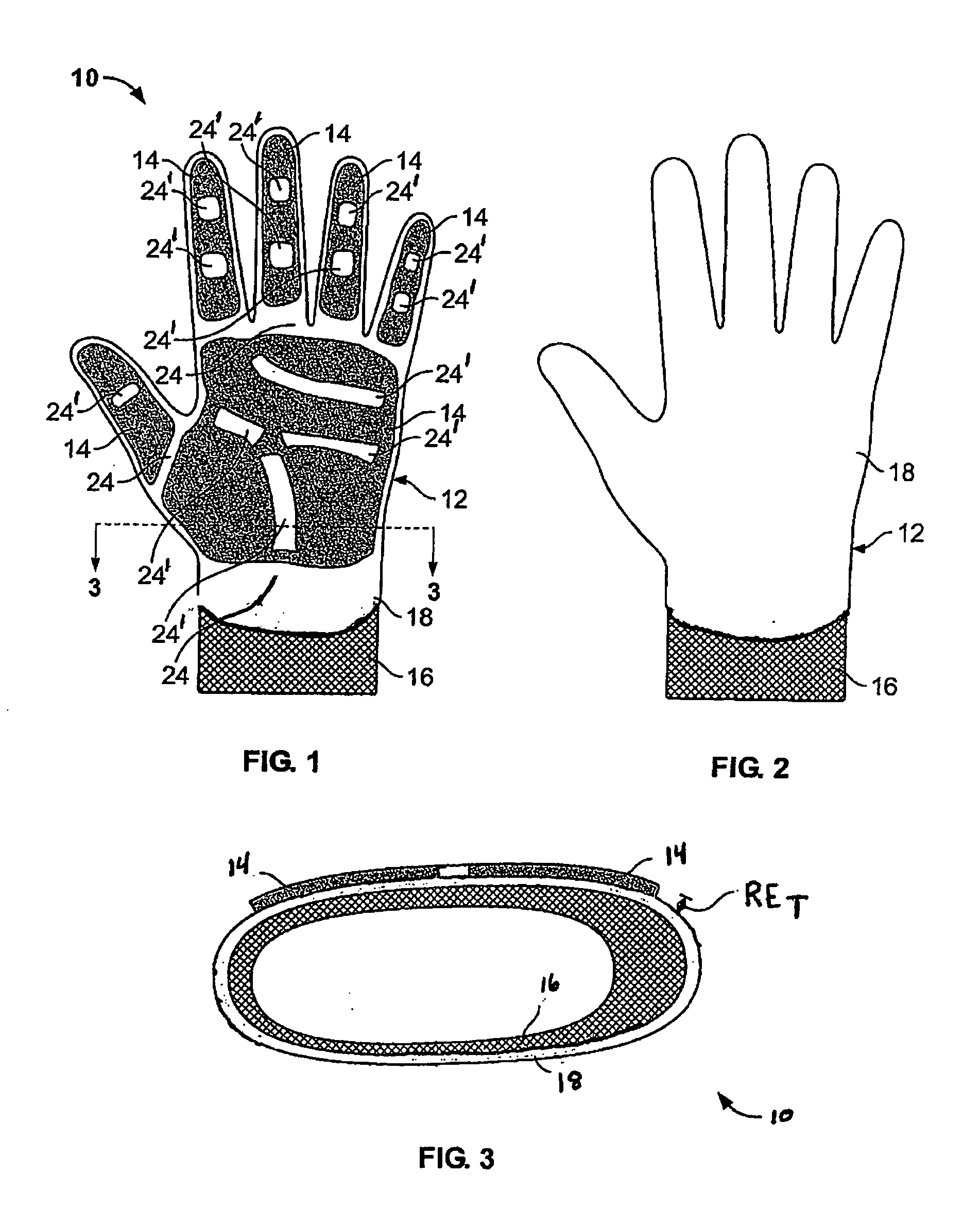

[0027] Referring to FIGS. 1 and 3, a multilayer glove 10 includes a composite 12 and a plurality of reinforcing elements 14. The composite 12 includes a fabric substrate 16 and a protective coating 18 and is shown in FIG. 2 without the reinforcing elements 14. With reference to FIGS. 1-3, the fabric substrate 16, protective coating 18, and reinforcing elements 14 will now be individually described.

[0028] The fabric substrate 16 has a shape similar to a human hand. The fabric substrate 16 is preferably string-knit. However, the fabric substrate 16 may be formed from any suitable natural or synthetic material, such as a woven, nonwoven, or knit fabric. In some embodiments of the invention, the multilayer glove 10 includes a substrate formed from plastic and / or rubber.

[0029] The protective coating 18 is preferably dip-coated onto the fabric substrate 16. The protective coating 18 may be disposed on part or all of the fabric substrate 16. Preferably, the protective coating 18 is at lea...

second embodiment

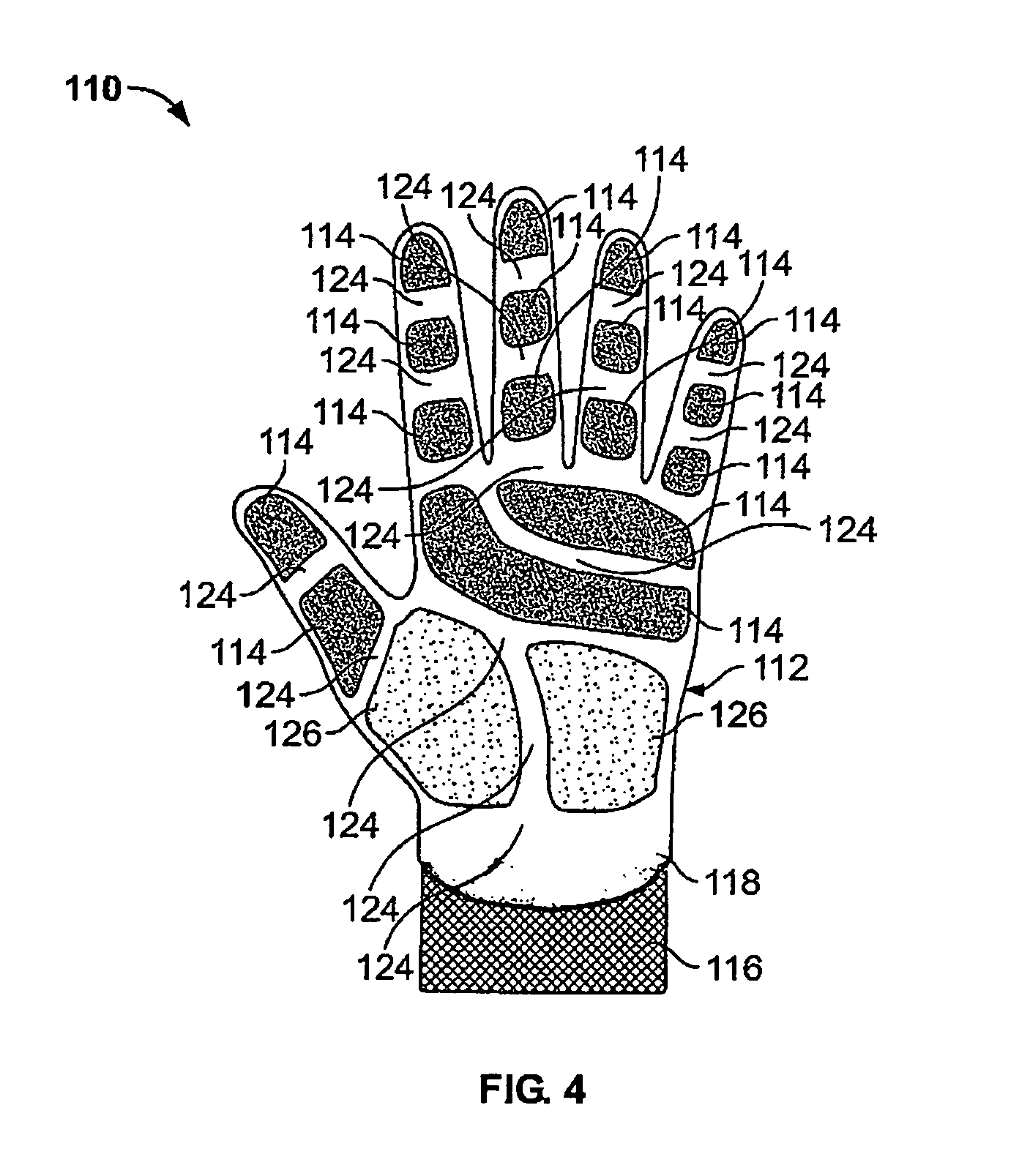

[0038] Referring to FIG. 4, the present invention is illustrated. Elements illustrated in FIG. 4 which correspond substantially to the elements described above with reference to FIGS. 1-3 have been designated by corresponding reference numerals increased by one hundred. The embodiment of the present invention shown in FIG. 4 is constructed in manners consistent with the foregoing description of the multilayer glove 10 shown in FIGS. 1 and 3, unless it is stated otherwise.

[0039] With reference to FIG. 4, a multilayer glove 110 has a fabric substrate 116 and a protective coating 118. The multilayer glove 110 further includes reinforcing elements 114 of a first color and additional reinforcing elements 126 having a second color. FIG. 4 shows sixteen reinforcing elements 114 of a first color and two additional reinforcing elements 126 of the second color. The reinforcing elements 114, 126 preferably form relief areas 124 therebetween. However, in contrast to each individual reinforcing ...

third embodiment

[0041] Referring to FIG. 5, the present invention is illustrated. Elements illustrated in FIG. 5 which correspond substantially to the elements described above with reference to FIGS. 1-3 have been designated by corresponding reference numerals increased by two hundred. The embodiment of the present invention shown in FIG. 5 is constructed in manners consistent with the foregoing description of the multilayer glove 10 shown in FIGS. 1 and 3, unless it is stated otherwise.

[0042] With reference to FIG. 5, a multilayer glove 210 has a fabric substrate 216 and a protective coating 218 formed on the back of the hand. Multilayer glove 210 further includes reinforcing elements 214 formed at the fingertips, knuckles, and back of the hand. As shown in FIG. 5, it is not required that the reinforcing elements 214 be positioned to form relief areas 24, and it is not required that individual reinforcing elements 214 have a relief area 24′ formed therethrough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com