Solderable elastic electric contact terminal

An electrical contact terminal and elastic technology, which is applied in the field of elastic electrical contact terminals, can solve the problems of the size limit of the conductive support layer, the insufficient adhesion of the conductive gasket material and the conductive support layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0032] 1. An embodiment

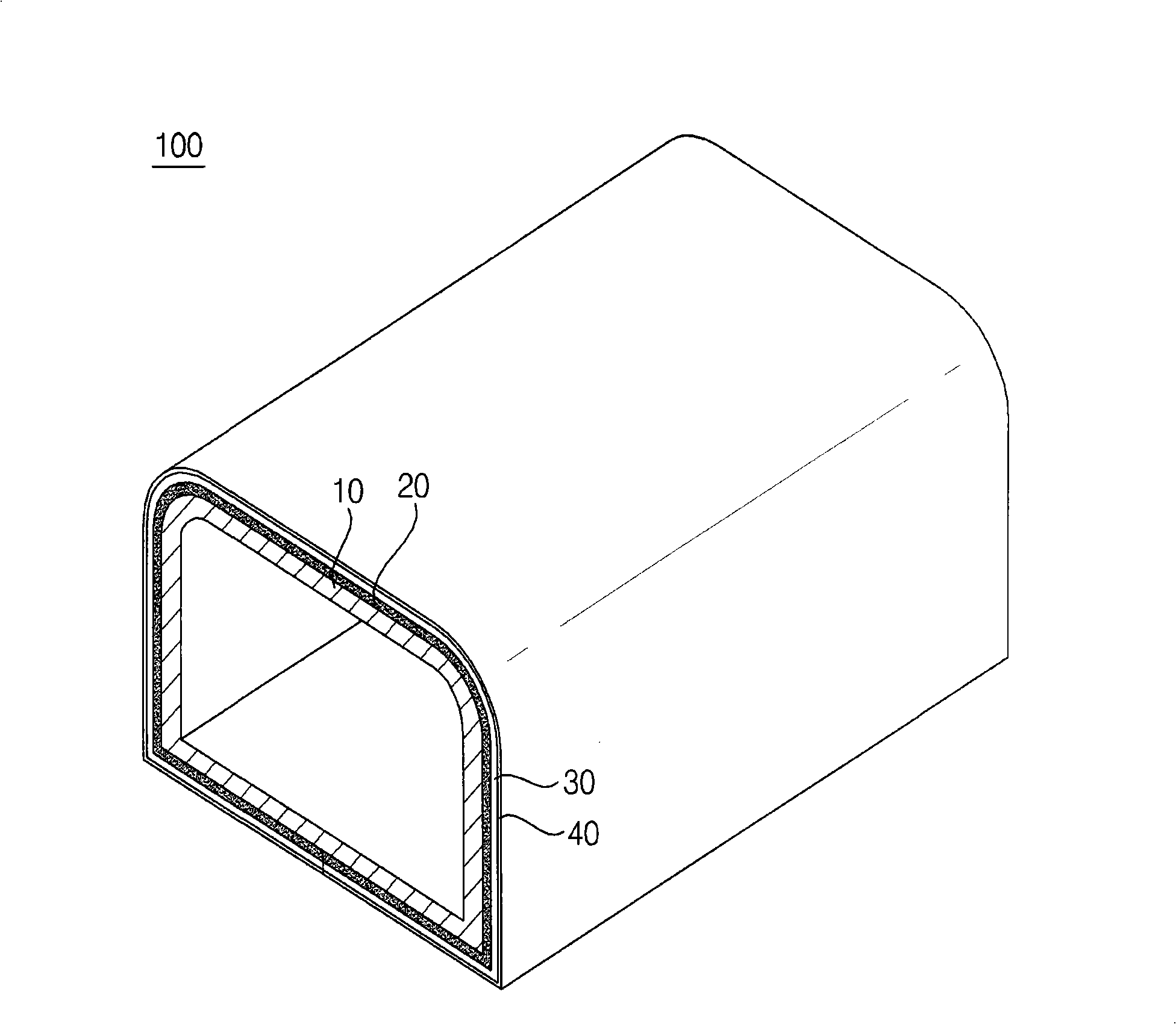

[0033] figure 1 is a diagram of an electrical contact terminal 100 according to one embodiment of the present invention.

[0034] refer to figure 1 , the elastic electrical contact terminal 100 includes a tubular insulating elastic core 10 , an insulating non-foam rubber coating layer 20 , and a heat-resistant polymer film 30 with a metal layer 40 on the surface stacked in sequence.

[0035] In this structure, a tubular elastic core manufactured by an extrusion process is applied, thereby reducing manufacturing cost, adjusting elastic force and pressing force to control the size of the through hole of the tube and efficiently manufacturing small products. In addition, the insulating non-foam rubber coating maintains adhesion and resiliency before and after the welding process and during repeated compression tests. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com