Optical disk device for data defect detection and use

a technology of optical disk and data, applied in the direction of digital signal error detection/correction, instruments, recording signal processing, etc., can solve the problems of conventional defect compensation device, inoperable control state, inability to carry out disturbance error interpolation, etc., to achieve complete cancellation of adverse effects, control of driving means, and defect detection period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

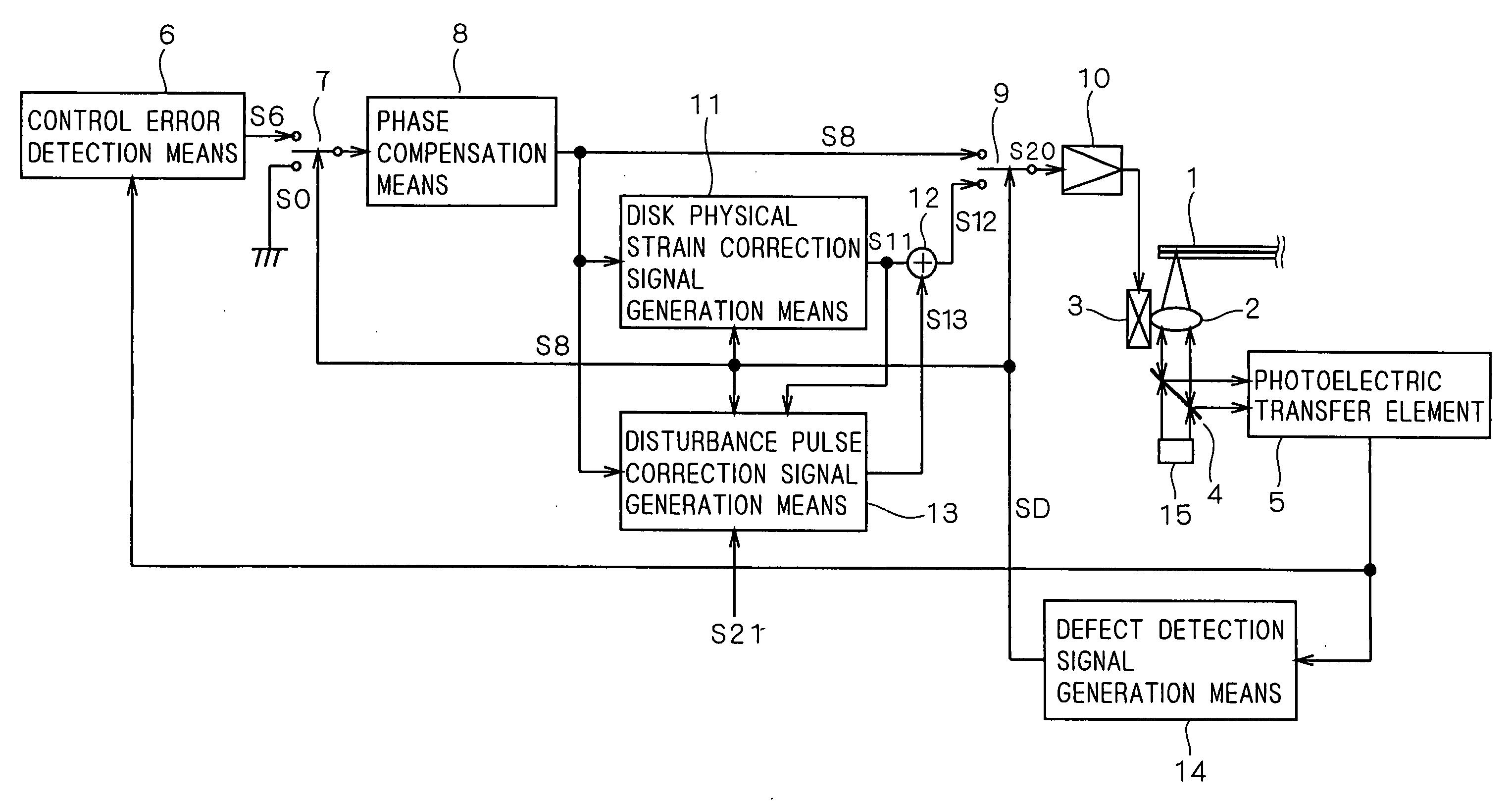

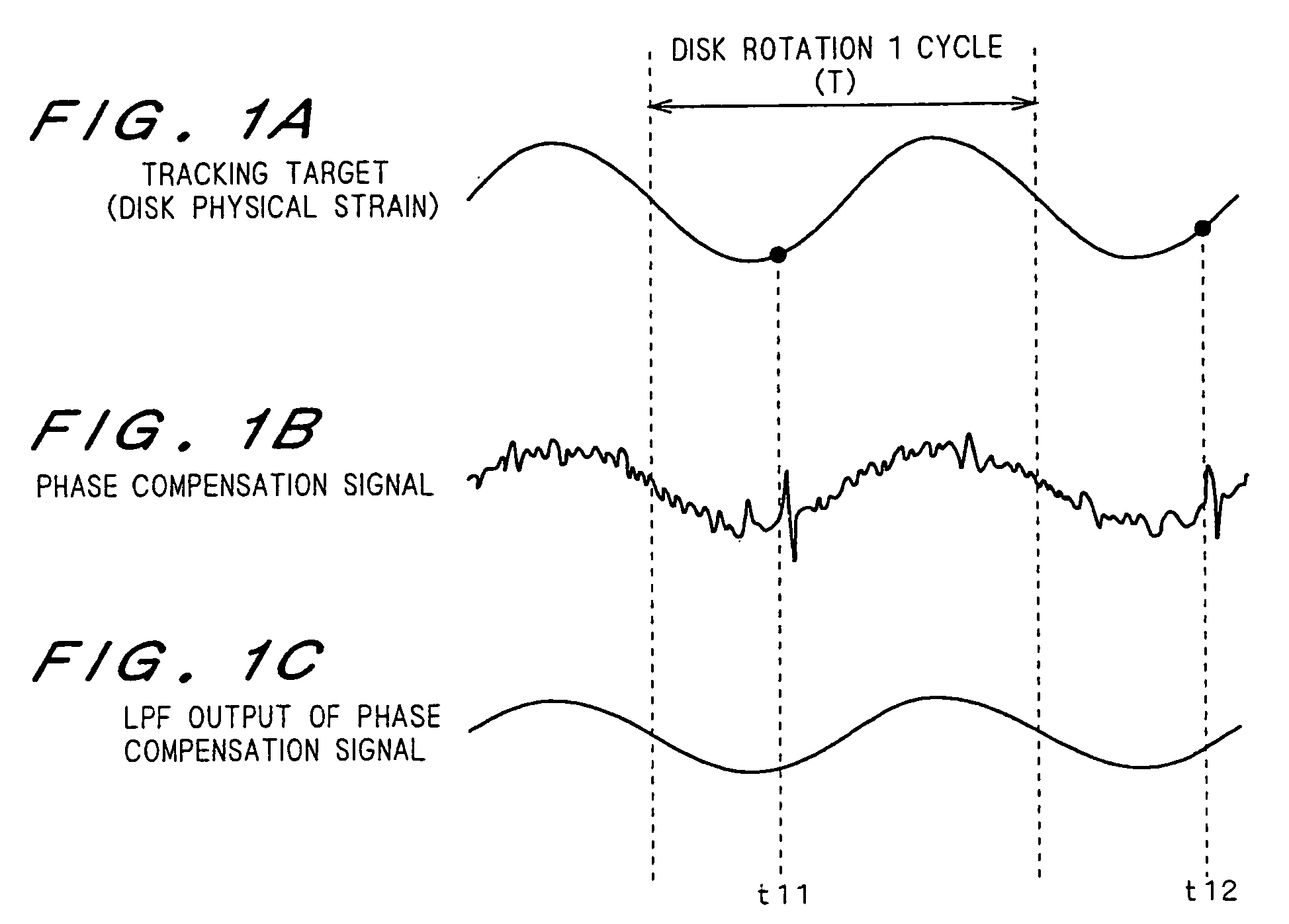

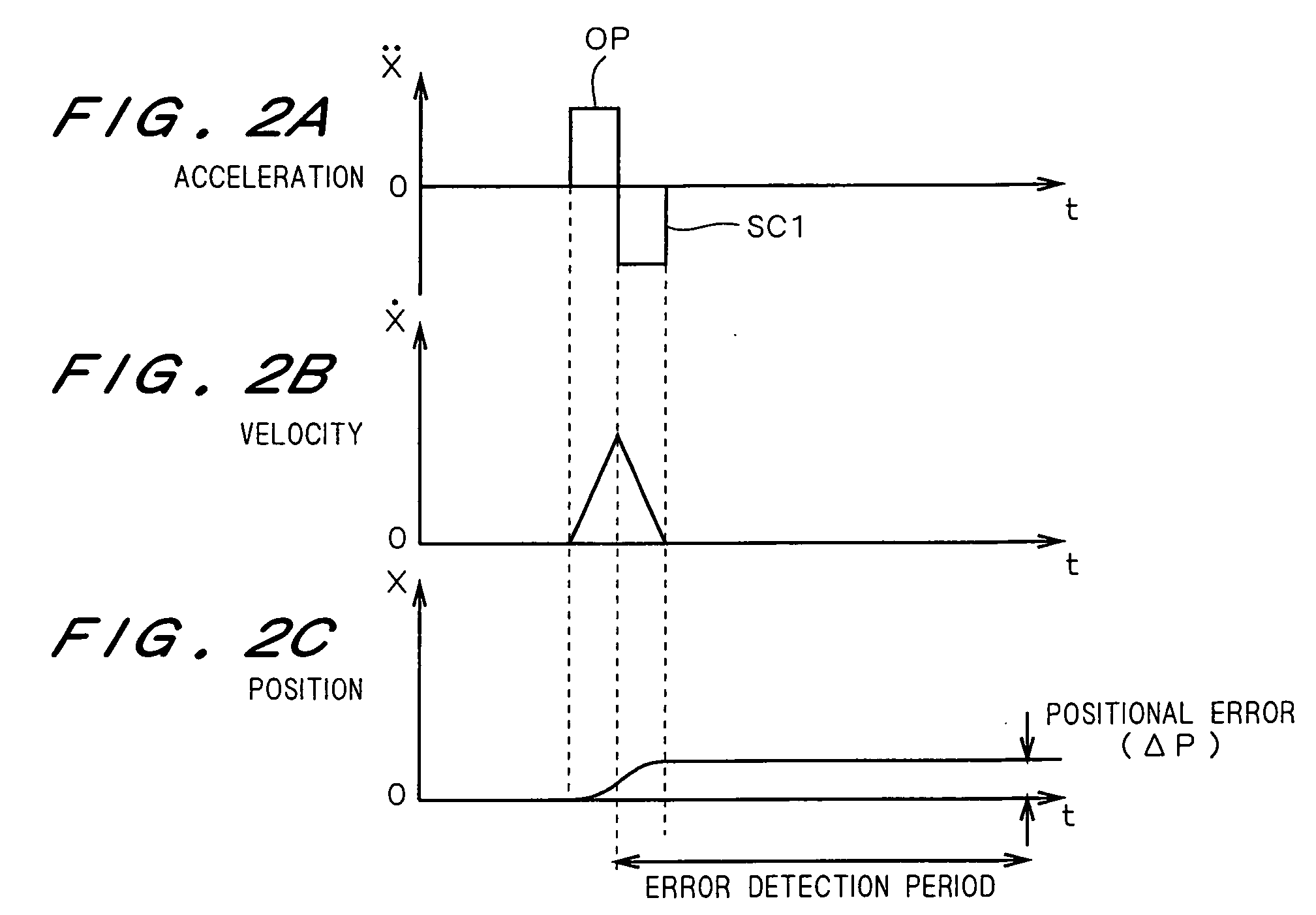

[0068] At a defect portion on an optical disk, an error signal forms a false error signal that is a disturbance error signal. For this reason, in the defect compensation control, upon detection of a defect, the control loop needs to be completely cut off, and upon completion of the defect, the control needs to be led in immediately, while maintaining the continuity of the control. The detection of a defect means that there is a lack of error signal; therefore, it is understood that, in order to ensure a stable, continuous lead-in operation at the defect end, a disk physical strain correction signal is required instead of the error signal, so as to provide a tracking operation on the disk physical strain (eccentricity and vertical deviation) even during defect period.

[0069] Therefore, the control signal that is applied to the driving coil 3 at the time of the error detection is defined as the addition of the disk physical strain correction signal used for tracking and interpolating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| defect | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| linear velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com