Tamper-indicating food container lid

a food container and lid technology, applied in the field of widemouth food containers, can solve the problems of troublesome installation process, relatively expensive process, and difficult opening of the package, and achieve the effect of shrink-wrapping operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

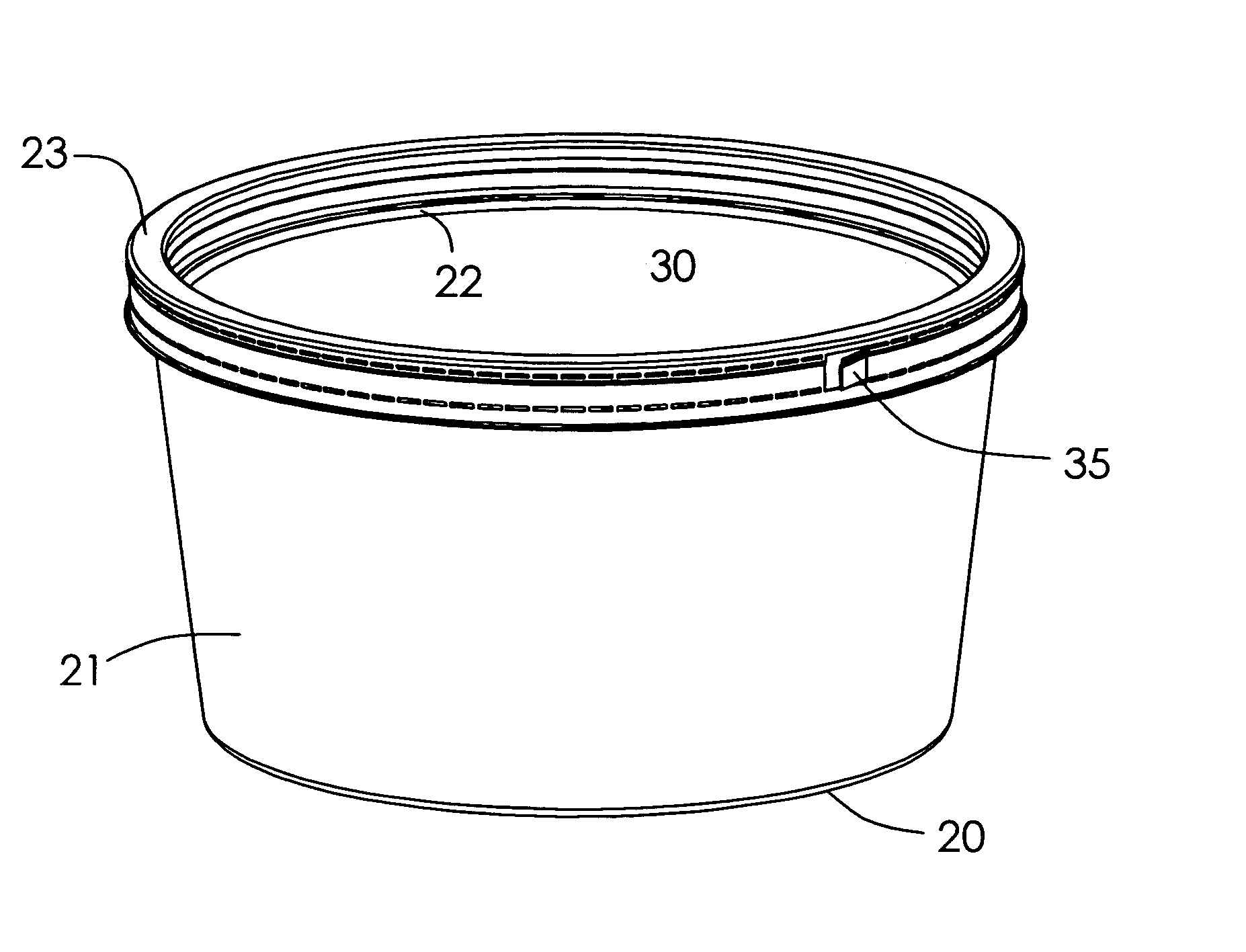

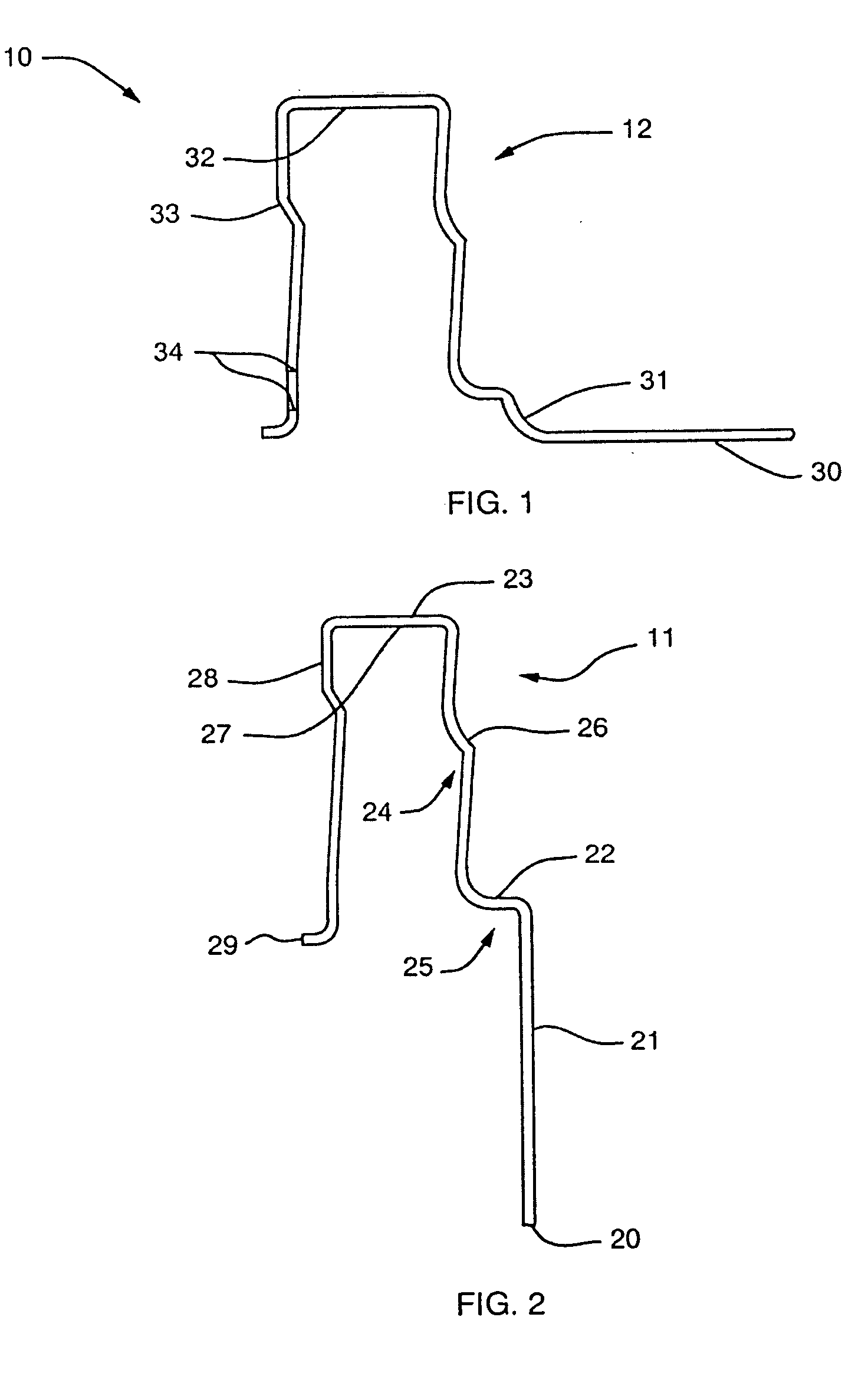

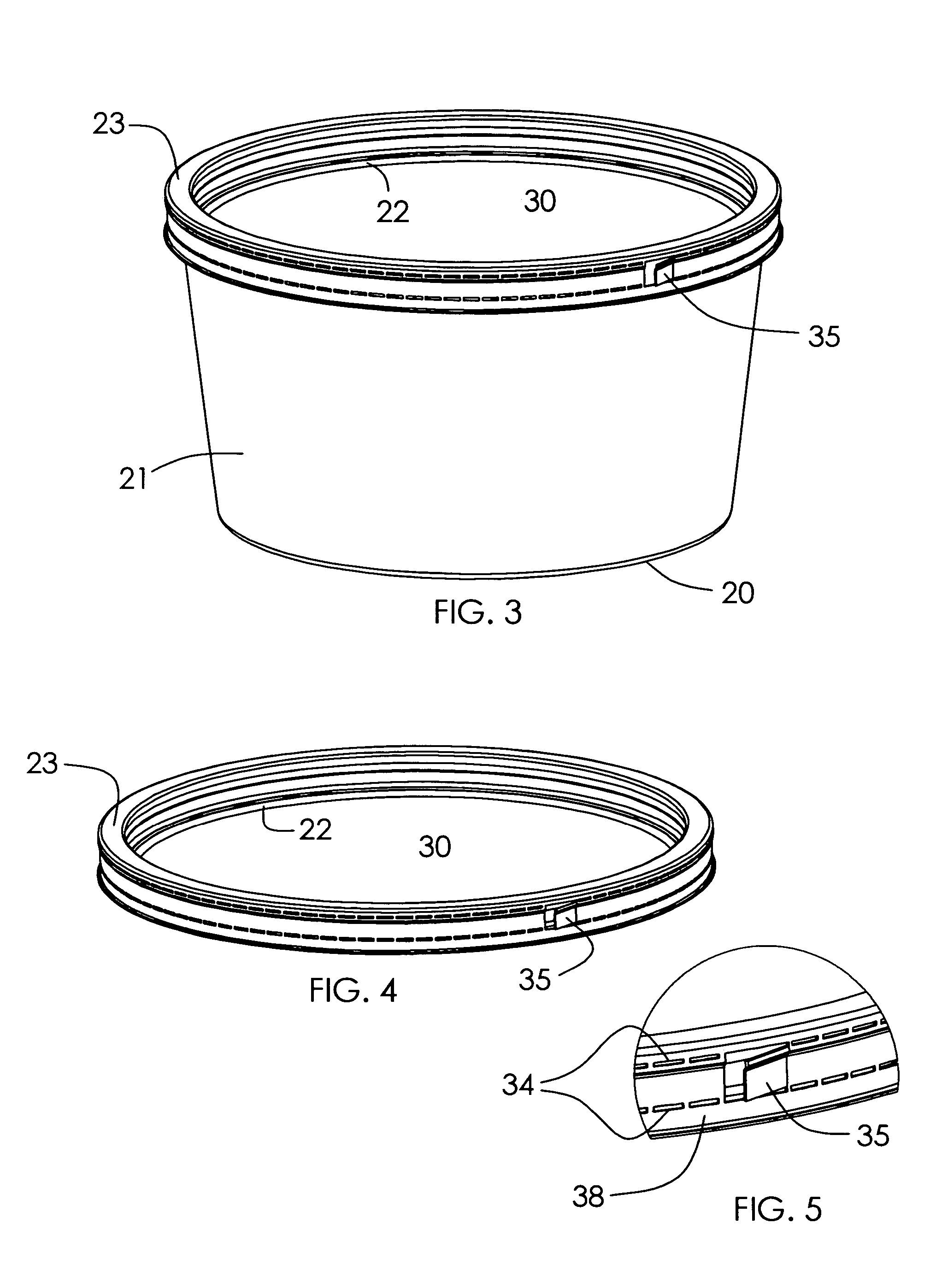

[0015] In accordance with the invention, the device, generally Indicated by reference character 10 comprises broadly: a container element 11 and a lid or cover element 12.

[0016] The container element 11 may be of known type, commonly formed by injection molding or thermoforming. It includes a bottom wall 20, an arcuate side wall 21, an upper rim section 22, and a lid-engaging portion 23 forming upper and lower recesses 24 and 25. It also includes a radially-extending recess 26 supporting a horizontal portion 27 and a bead-forming portion 28 defining an annular recess 29 engaged by the lid element upon first installation.

[0017] The lid element 12, commonly formed as a thermoforming or injection molding operation, and includes a horizontal main wall 30, an inner rim member 31, a radially-extending wall 32 and an outer rim member 33. The rim member 33 includes a single or multiple lines of slitting 34, preferably formed using a Laser beam, and as seen in FIG. 3, include an outwardly-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com