Case-hardened stainless steel foundry alloy and methods of making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

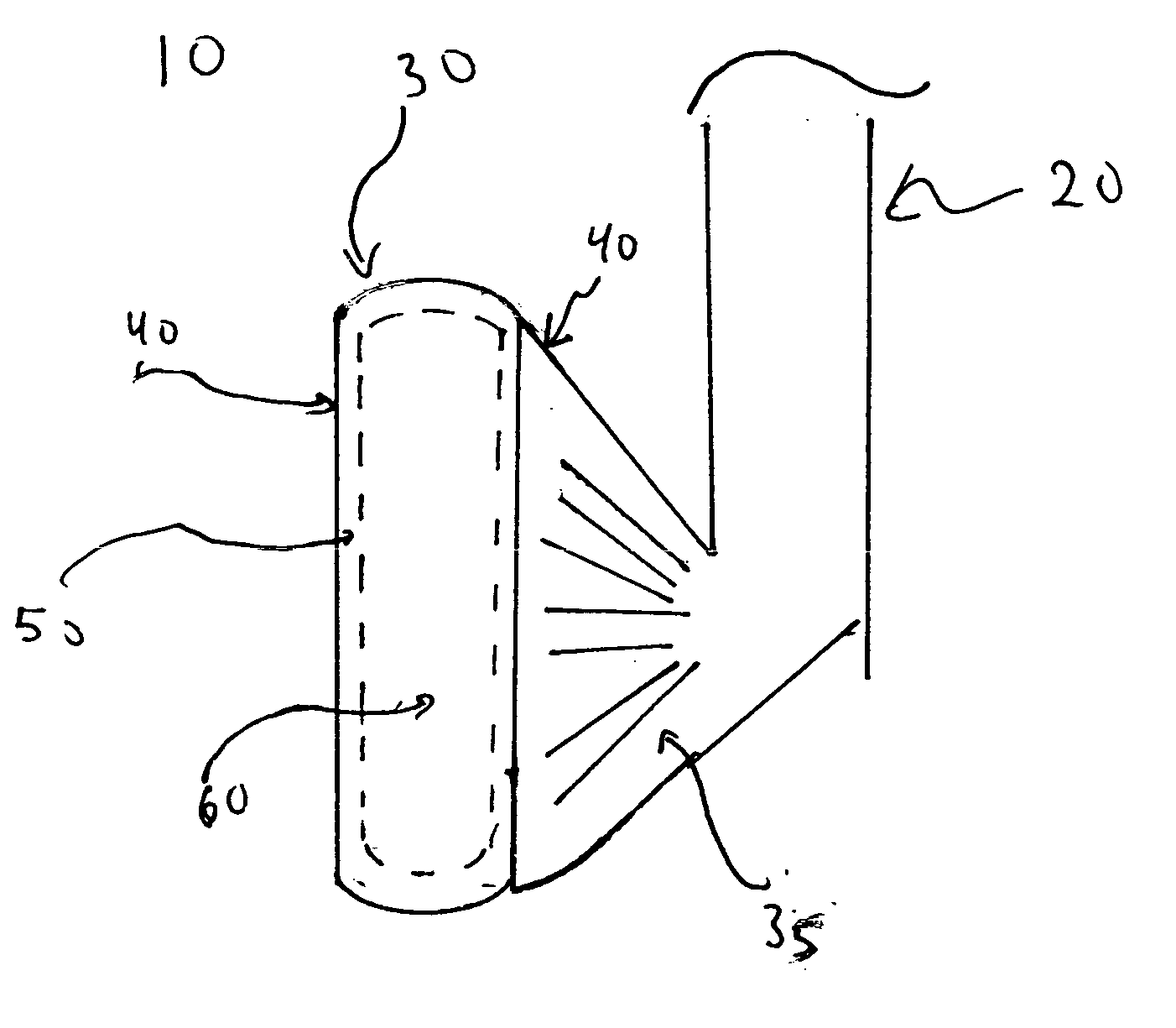

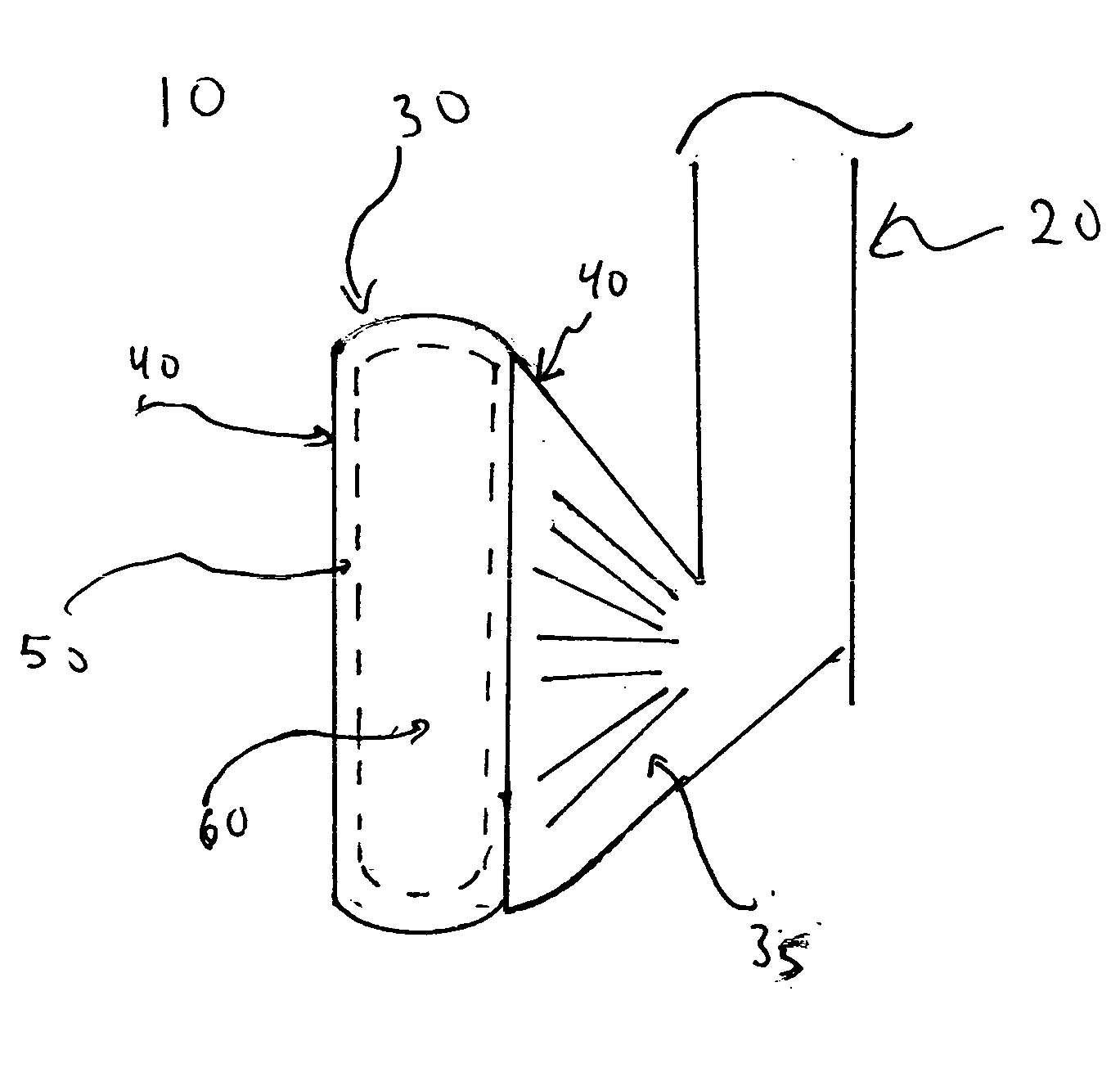

Image

Examples

Embodiment Construction

[0003] In accordance with one aspect of the present invention, a case-hardened stainless steel part is provided. The part is formed from a stainless-steel alloy, wherein the alloy generally comprises chromimum in an amount of from about 15.5 to about 18.5 percent by weight of the alloy and preferably includes carbon in an amount of from about 0.13 to about 0.29 percent by weight of the alloy, manganese in an amount of up to about 1.5 percent by weight of the alloy, silicon in an amount of from about 0.25 to about 1.5 percent by weight of the alloy and molybdenum in an amount up to about 1.0 percent by weight of the alloy, with iron present in a remaining amount based on the total weight of the alloy.

[0004] The cast part preferably has an outer surface and a case that defines a first layer proximate the outer surface. The cast part further comprises a core that defines a second layer distal from the outer surface. The core preferably has a hardness from about HRB 80 (Rockwell Hardne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com