Insulative panels for a railway boxcar

a boxcar and insulation panel technology, applied in the field of railroad freight cars, can solve the problems of insufficient boxcars to transport over large distances, inability to meet the needs of insulated enclosure floors,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

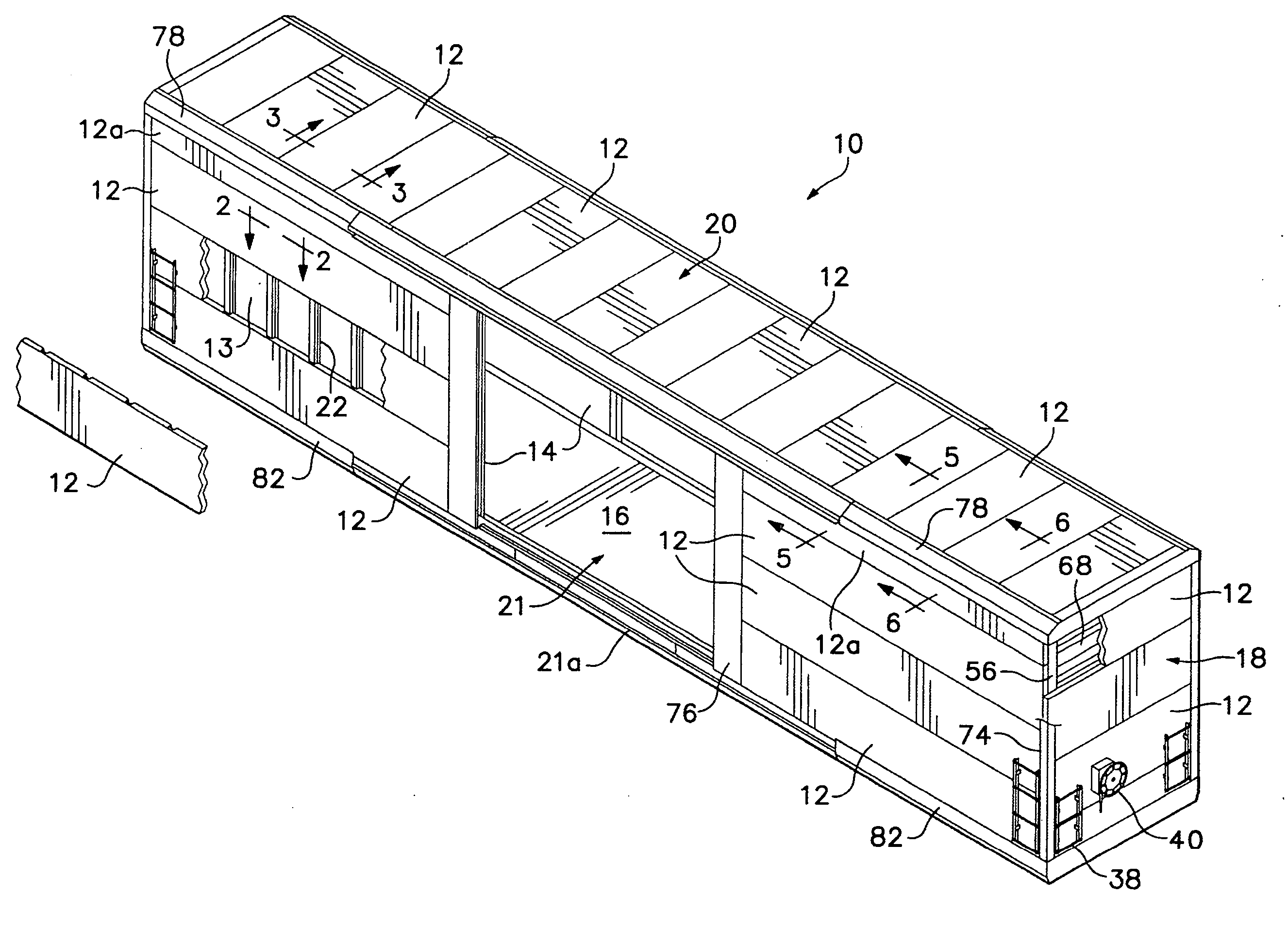

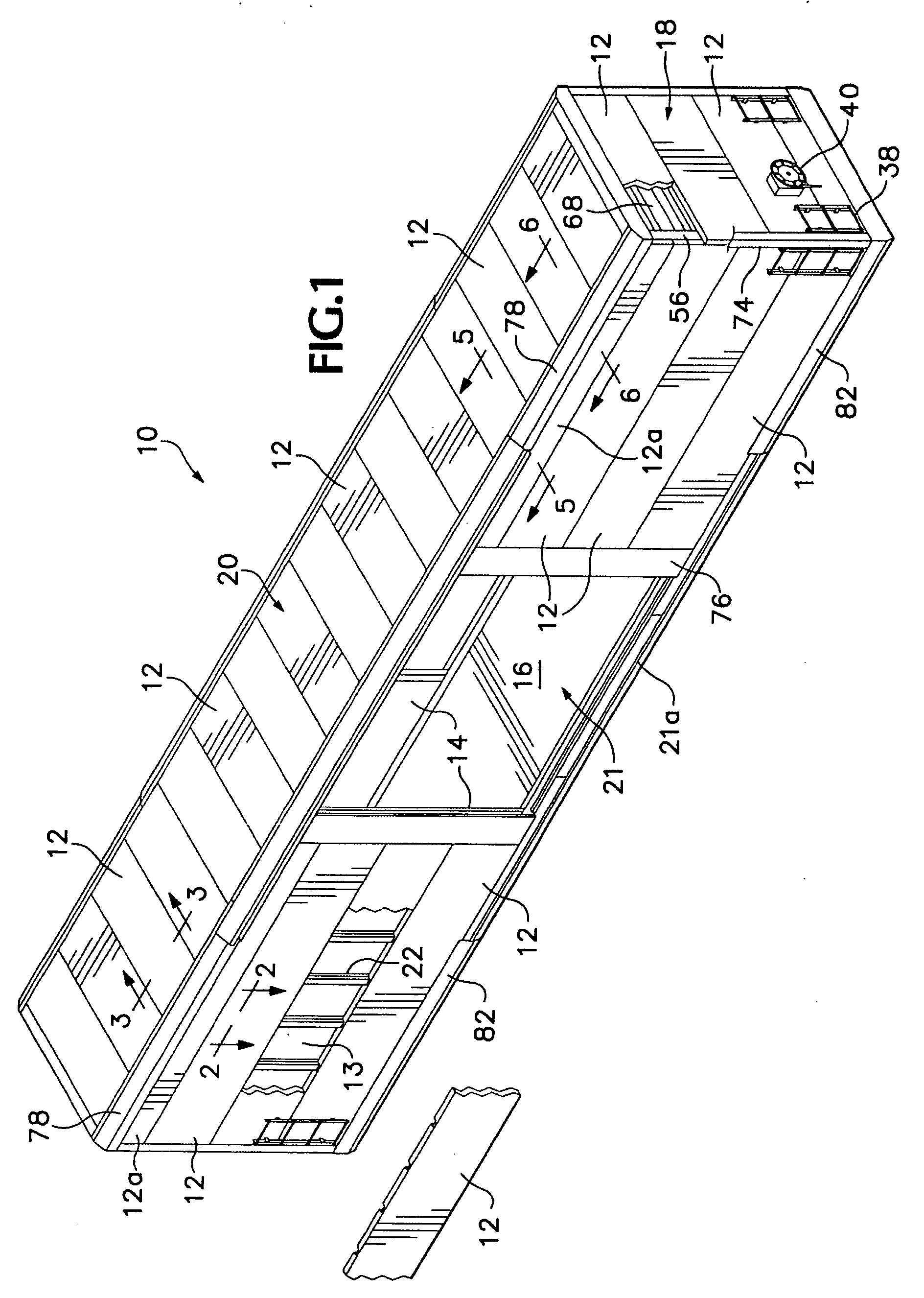

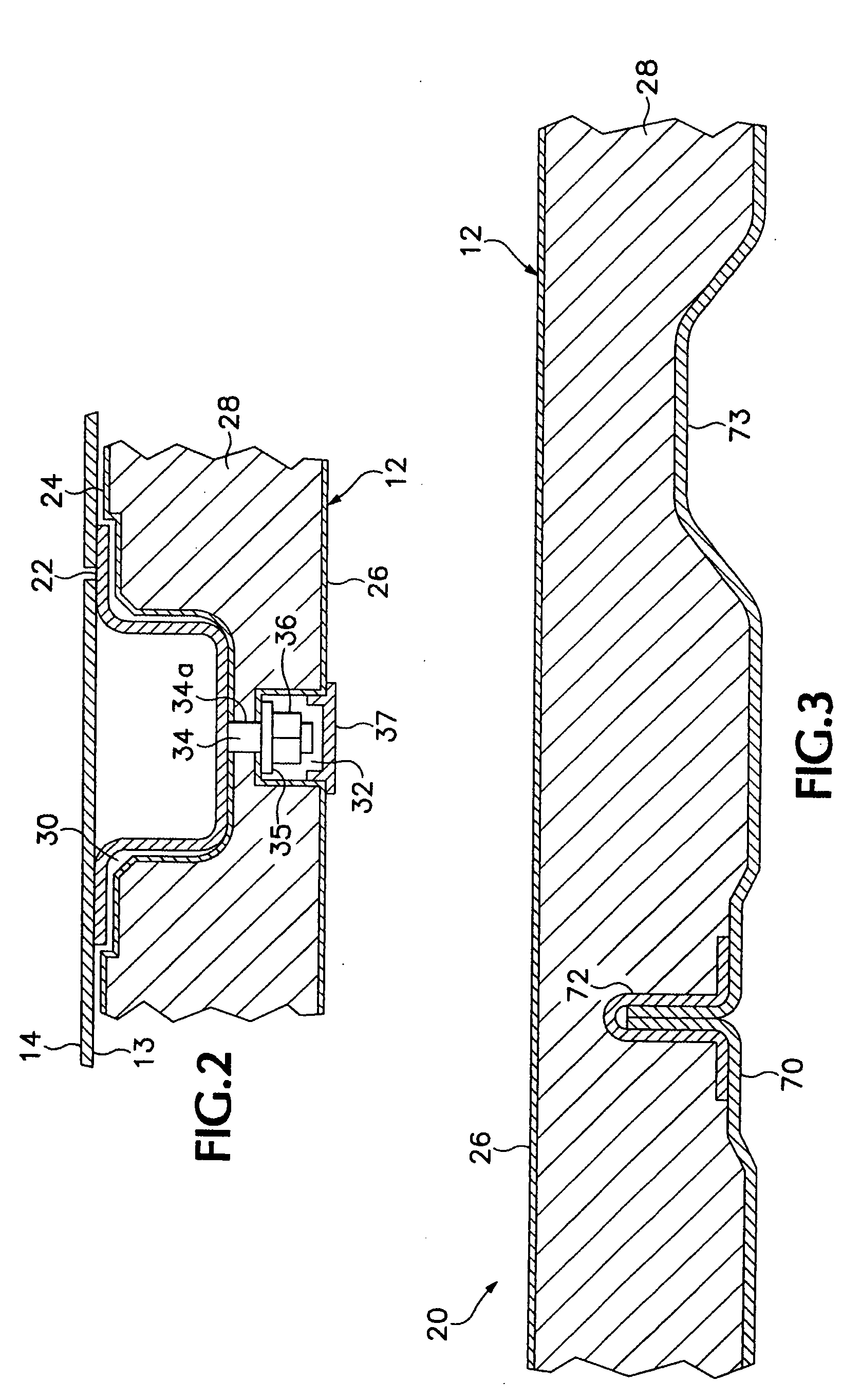

[0020]FIG. 1 shows an exemplary boxcar 10 having opposed side walls 14, opposed end walls 18, a roof 20, and a floor 16, each structurally supported by an undercarriage 15 (shown in FIGS. 4-6) mounted on a truck (not shown) or other member that facilitates movement of the exemplary boxcar 10 along a railroad track. Each of the foregoing side walls 14, undercarriage 15, floor 16, end walls 18, and roof 20 may preferably be fashioned from steel, iron, or other rigid metal members that provide strength to the boxcar 10 and resist deformation of the boxcar due to loading weights and other forces.

[0021] The side walls 14, end walls 16, and roof 20 of the exemplary boxcar 10 may define an exterior, outwardly facing surface 13 of the boxcar 10 through which a great deal of heat would normally enter during transport of cargo. To insulate the exemplary boxcar 10, and thereby reduce the amount of heat passing through the surface 13, thermally insulative panels 12 may be positioned proximate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com