Sports boot shell with comfort sock

a technology of comfort socks and sports boot shells, applied in the field of sports boot shells or sports boot shell subassemblies, can solve the problems of insufficient comfort and stiffness, too uncomfortable, and insufficient solution to meet comfort and stiffness constraints, and achieve the effect of limiting heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

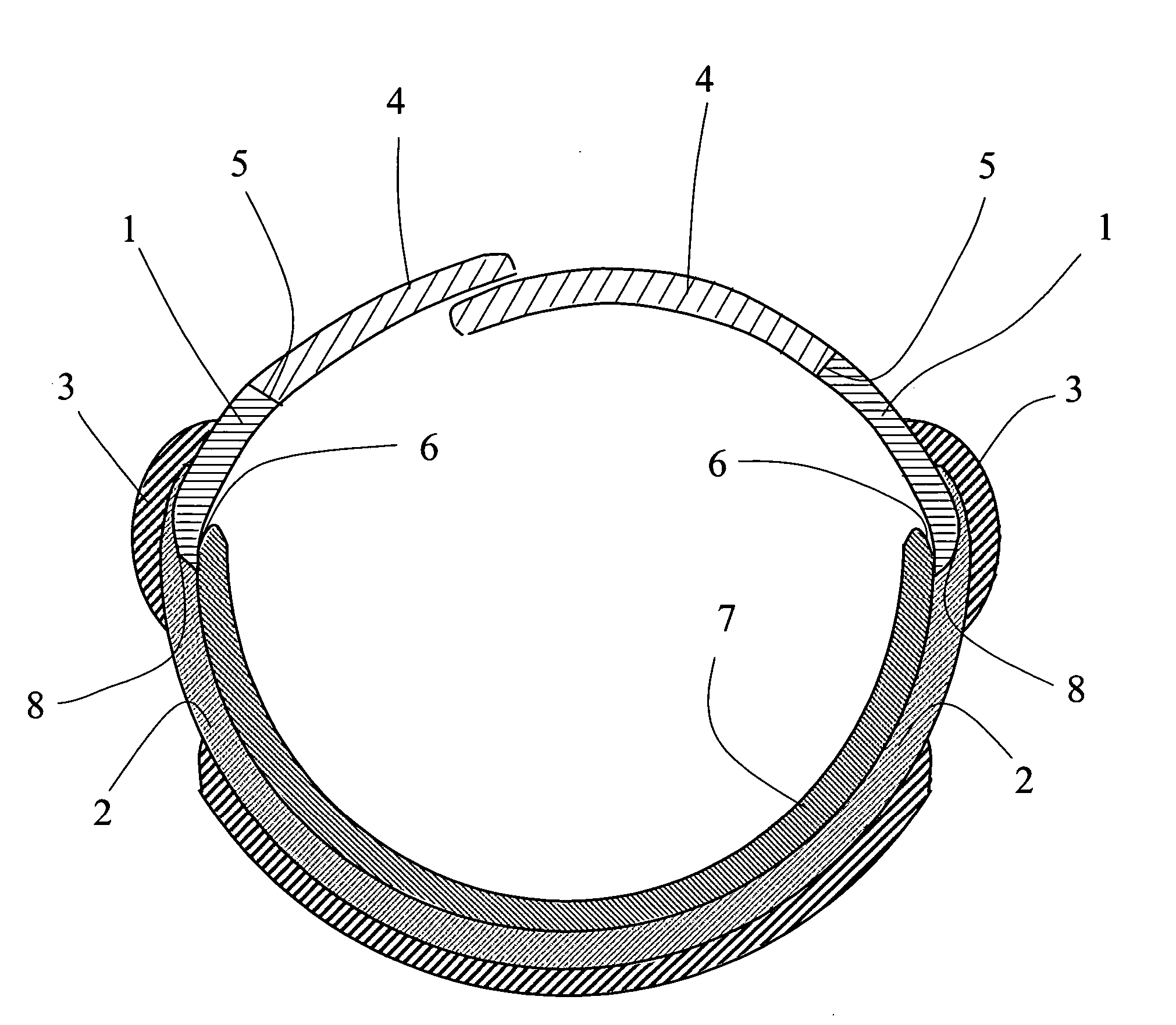

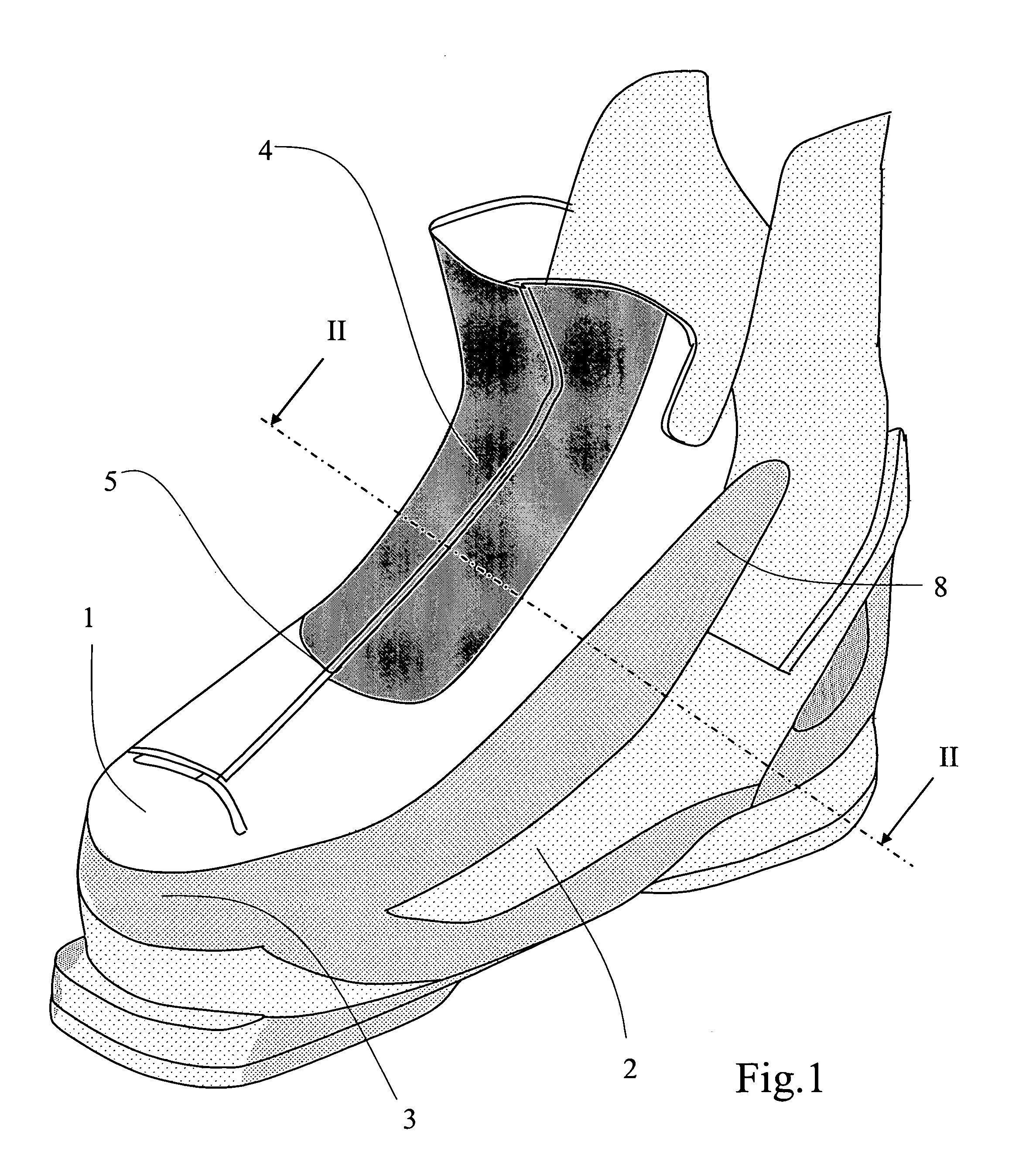

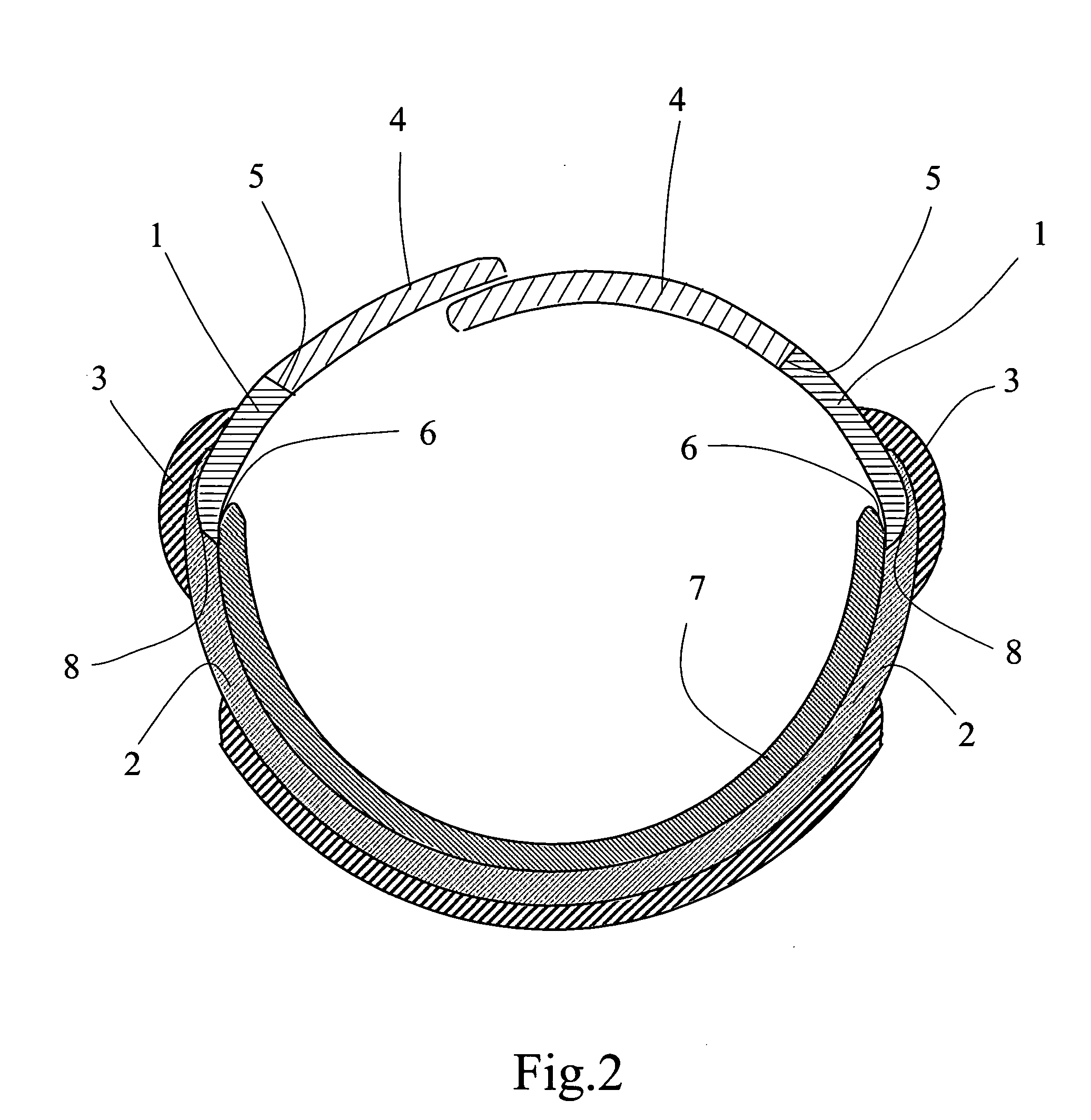

[0030]FIGS. 1 and 2 illustrate a very sophisticated embodiment of the invention applied to a ski boot shell. This shell is composed of three plastics materials 1, 2, 3 obtained by means of three injection-molding operations. The zone in plastics material 1 is relatively flexible and connected to more flexible parts 4, in leather, plastics or fabric, by means of stitching 5 in order to form two flexible flaps in the zone corresponding to the instep and extending as far as the lower leg in order to make it easier to put the boot on. The other end of these parts in plastics material 1 is connected by stitching 6 to an inner sock 7 that therefore has a notch at the level of the instep zone, as shown in FIG. 2.

[0031] The sock 7 occupies a wide surface around the foot and includes aluminum in order to form a wall having a property of reflecting thermal radiation, which has the effect of preventing cooling of the inner liner and, more particularly, of the foot placed in this liner, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection | aaaaa | aaaaa |

| thermal radiation | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com