Washing machine having a condensing duct

a technology of condensing duct and washing machine, which is applied in the field of washing machines, can solve the problems of not producing a relatively high scattering effect of condensed water, and achieve the effect of enhancing the scattering efficiency of condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

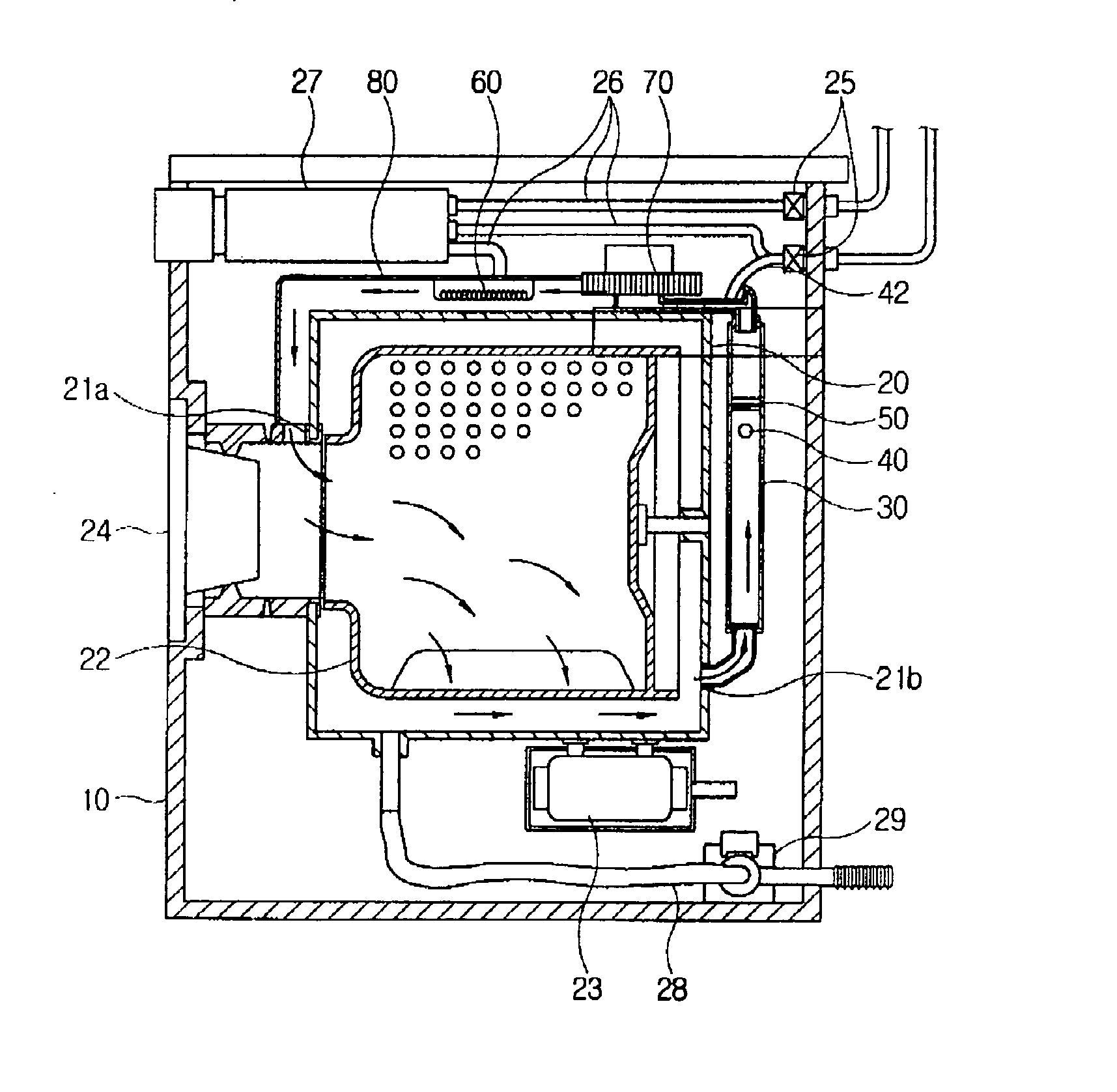

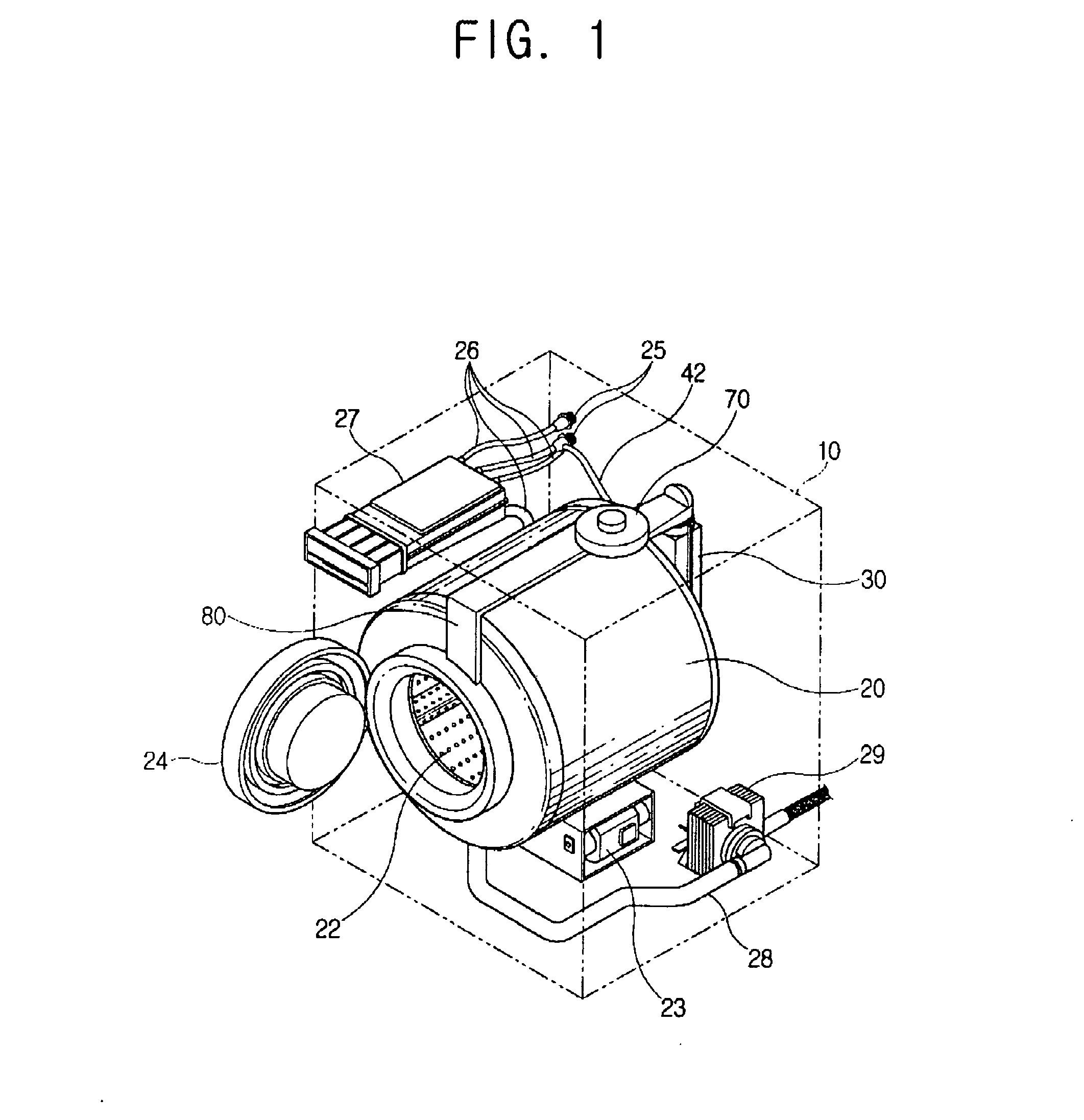

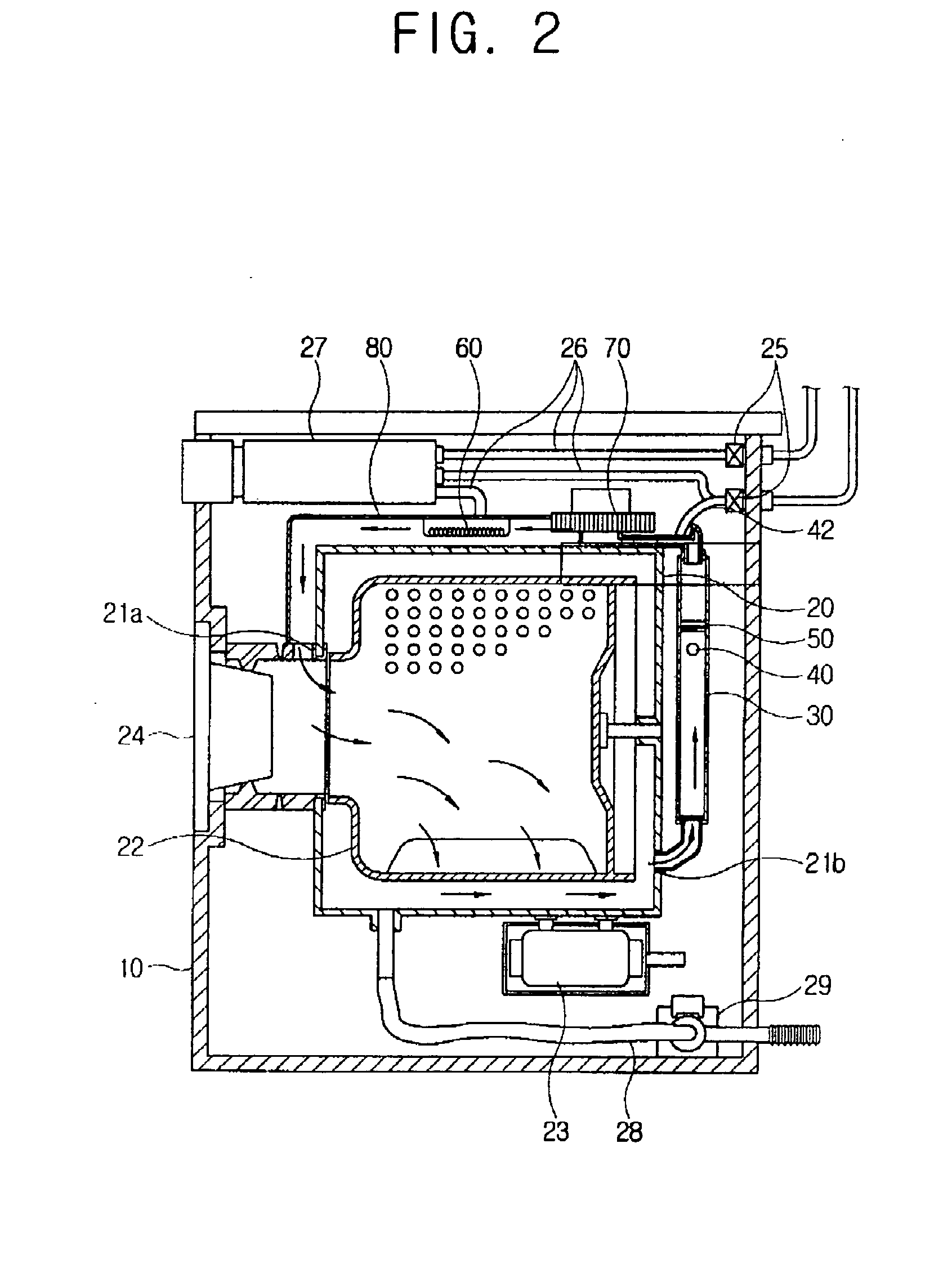

[0036] The above and / or other aspects and advantages of the present invention will become apparent and more readily appreciated from the following description of the exemplary embodiments, taken in conjunction with the accompanying drawings of which:

[0037] Referring to FIGS. 1 and 2, a drum-type washing machine according to the present invention comprises a main casing 10, a cylinder-type drum 20 installed inside the main casing 10 in which the laundry is put, a cylinder-type washing tank 22 having dehydrating holes on the wall face thereof, a driving motor 23 provided below a lower part of the drum 20, rotating the washing tank 22 forwardly or backwardly, to thereby perform operations to wash, rinse and dehydrate the laundry, and a door 24 installed in front of the main casing 10, for opening and closing the body casing 10.

[0038] Over the top of the drum 20 are provided water supplying units such as water supplying valves 25, water supply tubes 26, a detergent dissolving unit 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com