Method for manufacturing light emitting device

a technology of light emitting devices and manufacturing methods, which is applied in the direction of static indicating devices, instruments, sustainable buildings, etc., can solve the problems of initial deterioration and aging drive of display devices, and achieve the effects of reducing variation in deterioration over time, high reliability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 1

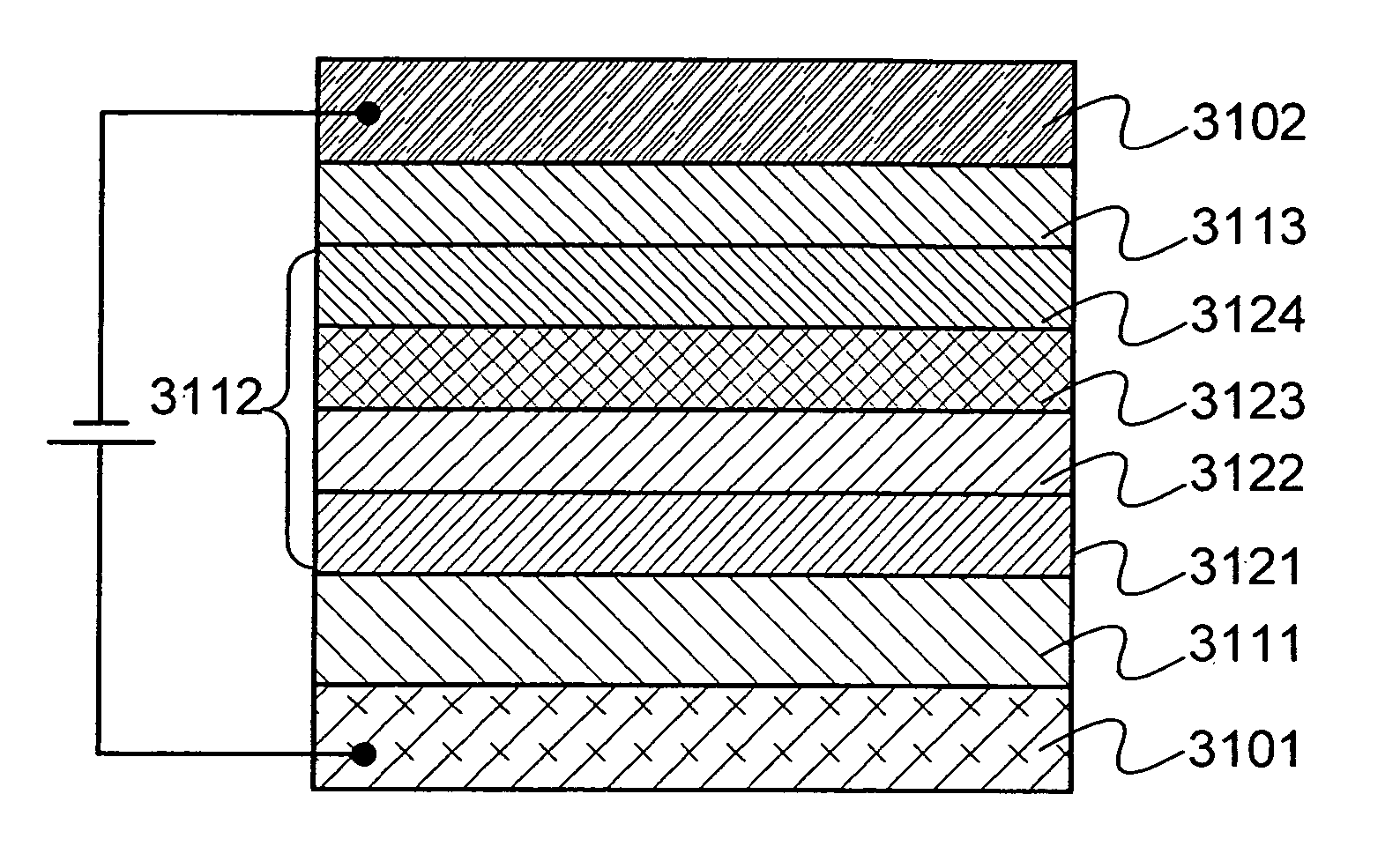

[0050] As to a light emitting device, the steps of depositing a light emitting layer material and sealing are performed after completing the step of manufacturing a TFT. The light emitting device in this state is referred to as a light emitting module. In the light emitting module, a wiring for inputting an external signal is connected to a display panel which is provided with each element. Thereafter, the light emitting module is subjected to aging for a certain period, mounted on a product, and then completed as a light emitting device. In this embodiment mode, drive employed for aging (aging drive) is explained below.

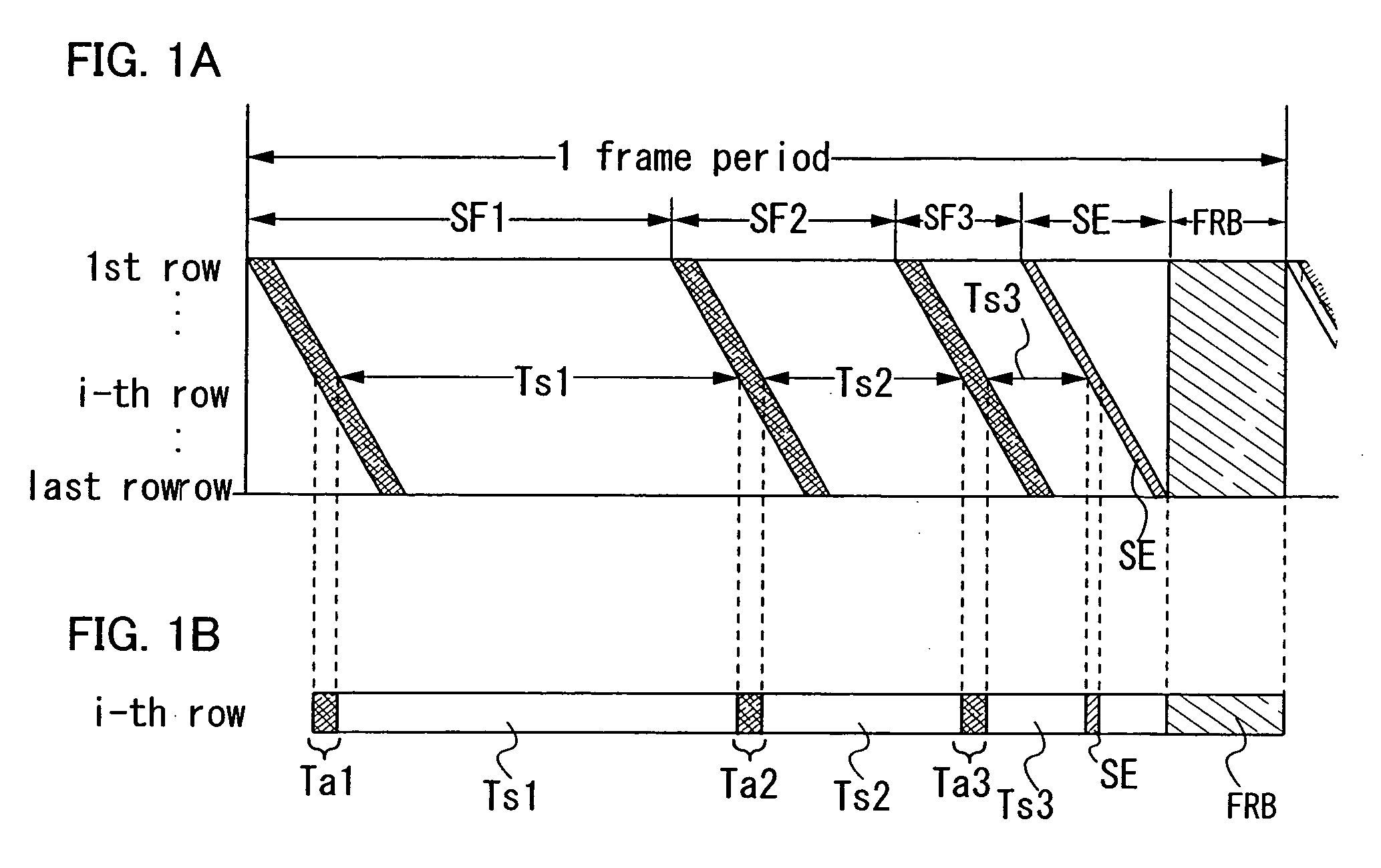

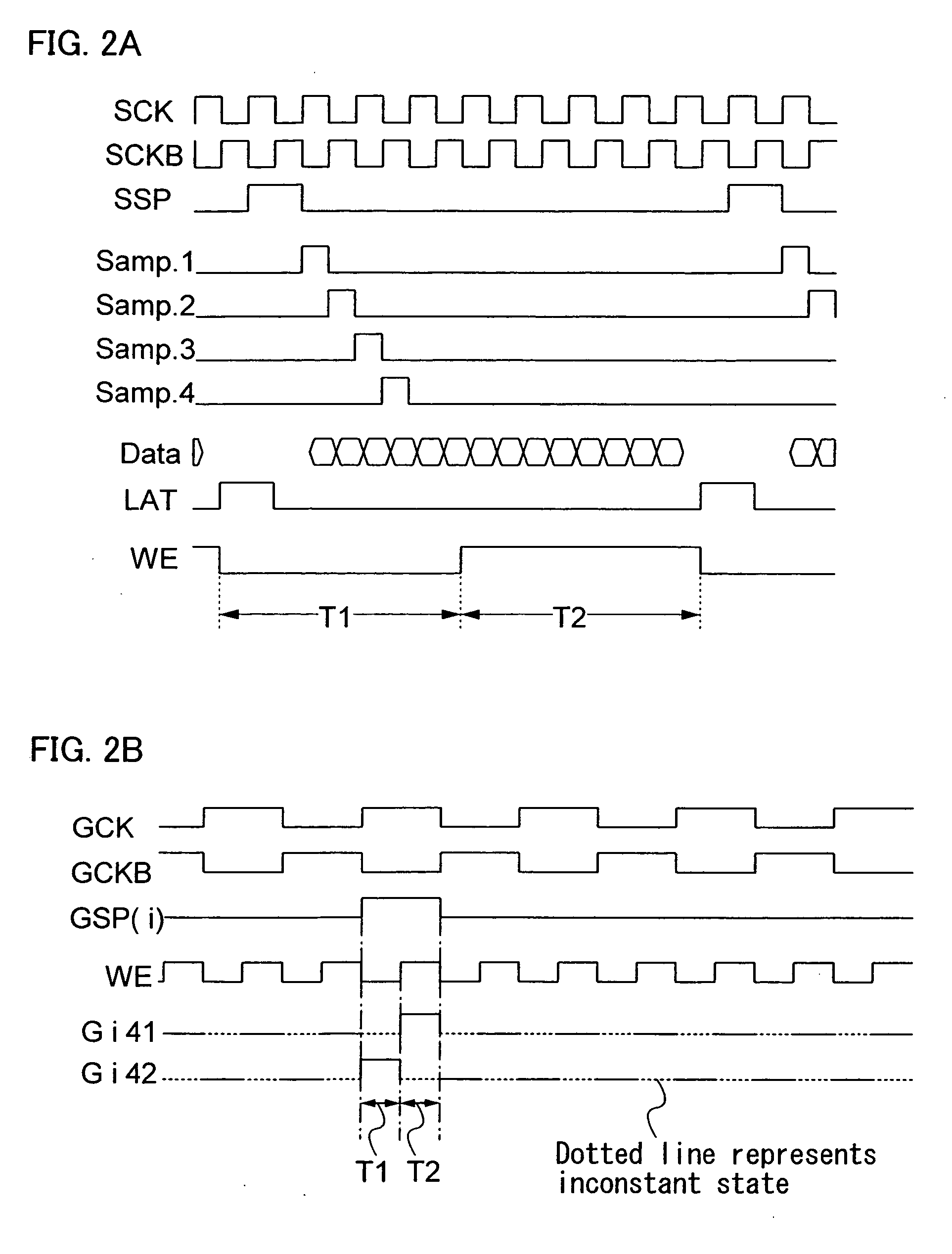

[0051] In this embodiment mode, a time gray scale method in which one frame period is divided into a plurality of subframe periods is applied to the aging drive. Forward voltage can be applied, and in addition, reverse voltage can also be applied. Note that, if voltage applied to make a light emitting element emit light is referred to as forward voltage, applying re...

embodiment mode 2

[0066] The present invention may further have a function of correcting for deterioration in a light emitting element after mounting on a product. Thus, explained in this embodiment mode is a structure of a display panel in a light emitting module mounted with a monitor circuit which serves to correct for deterioration in the light emitting element. Note that an active type light emitting device is described in this embodiment mode.

[0067] In FIG. 3, a pixel portion 40, a signal line driver circuit 43, a first scanning line driver circuit 41, a second scanning line driver circuit 42, and a monitor circuit 64 are provided over an insulating substrate.

[0068] The pixel portion 40 is provided with a plurality of pixels 10, and each pixel is provided with a light emitting element 13 and a transistor 12 which is connected to the light emitting element 13 and has a function of controlling current supply (hereinafter referred to as a driver transistor). The light emitting element is connect...

embodiment mode 3

[0095] In the invention, after mounting the light emitting module on a product, reverse voltage in addition to forward voltage may be applied to the light emitting element 13 and the monitor light emitting element 66. Thus, the case of applying reverse voltage after mounting the light emitting module is explained in this embodiment mode.

[0096] Explanation is made using the monitor light emitting element66. In order to apply reverse voltage, anode and cathode potentials of the monitor light emitting element are interchanged. Therefore, a potential of the monitor line 113 is made lower than that of the power source 18. As well as the light emitting element 13, in order to apply reverse voltage, anode and cathode potentials may be interchanged.

[0097] At this time, the cathode potential is preferably reversed after reversing the anode potential in the light emitting element 13 and the monitor light emitting element 66. After a predetermined reverse voltage period, the anode potential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com