Depletion device for bag in box containing viscous liquid

a technology of depletion device and viscous liquid, which is applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of difficult to achieve performance, high residue of ink, and high viscosity of ink, and achieves the effect of improving viscosity and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

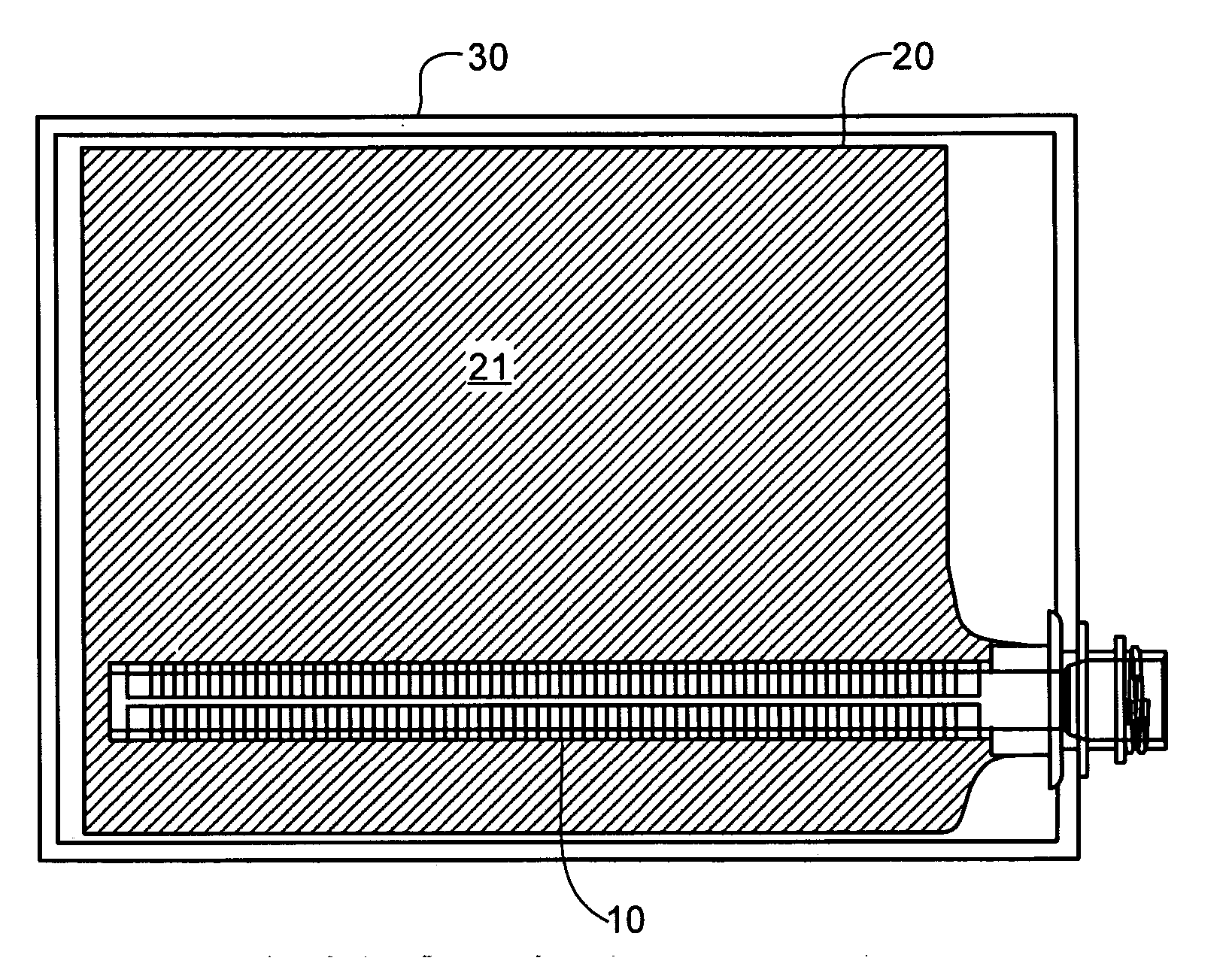

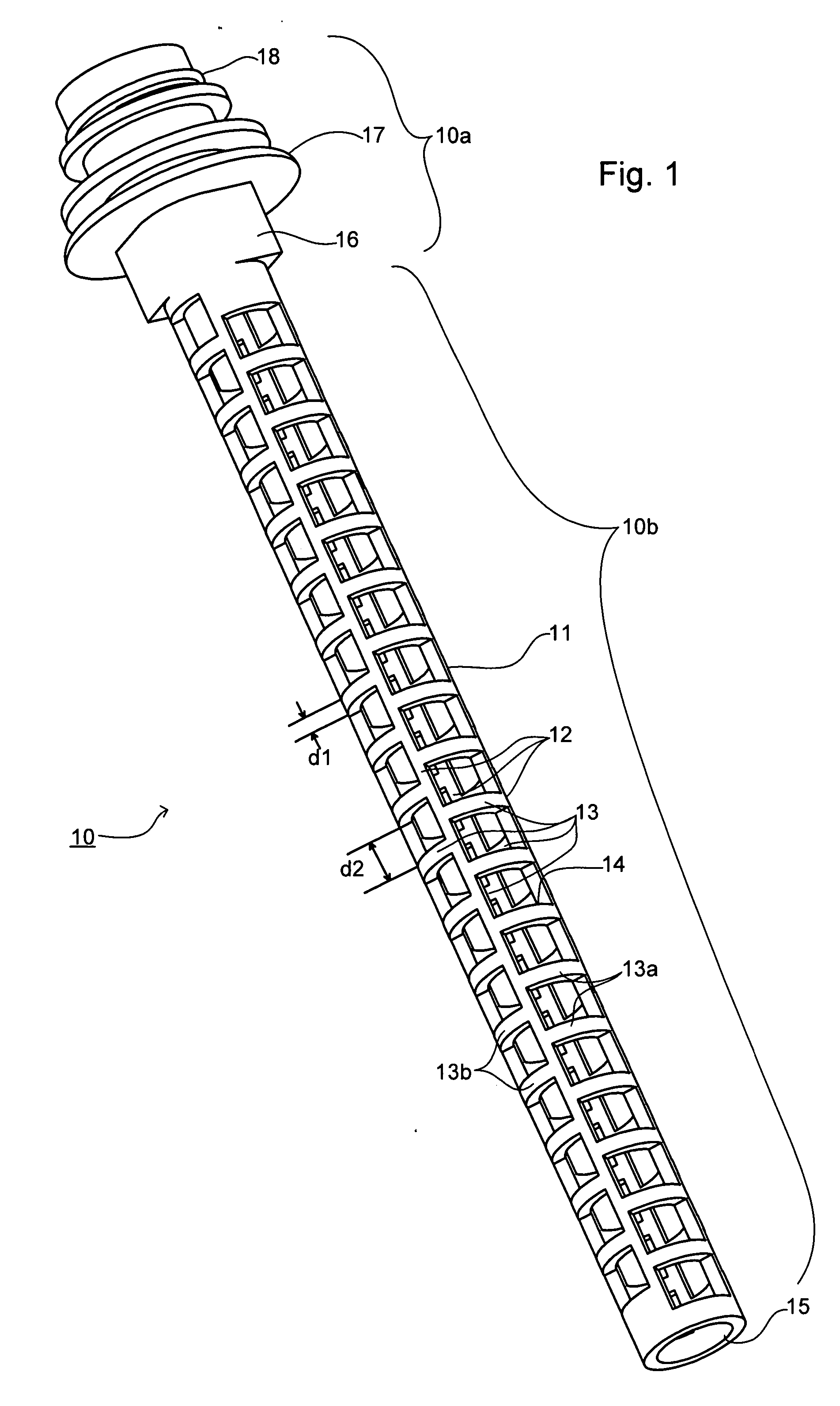

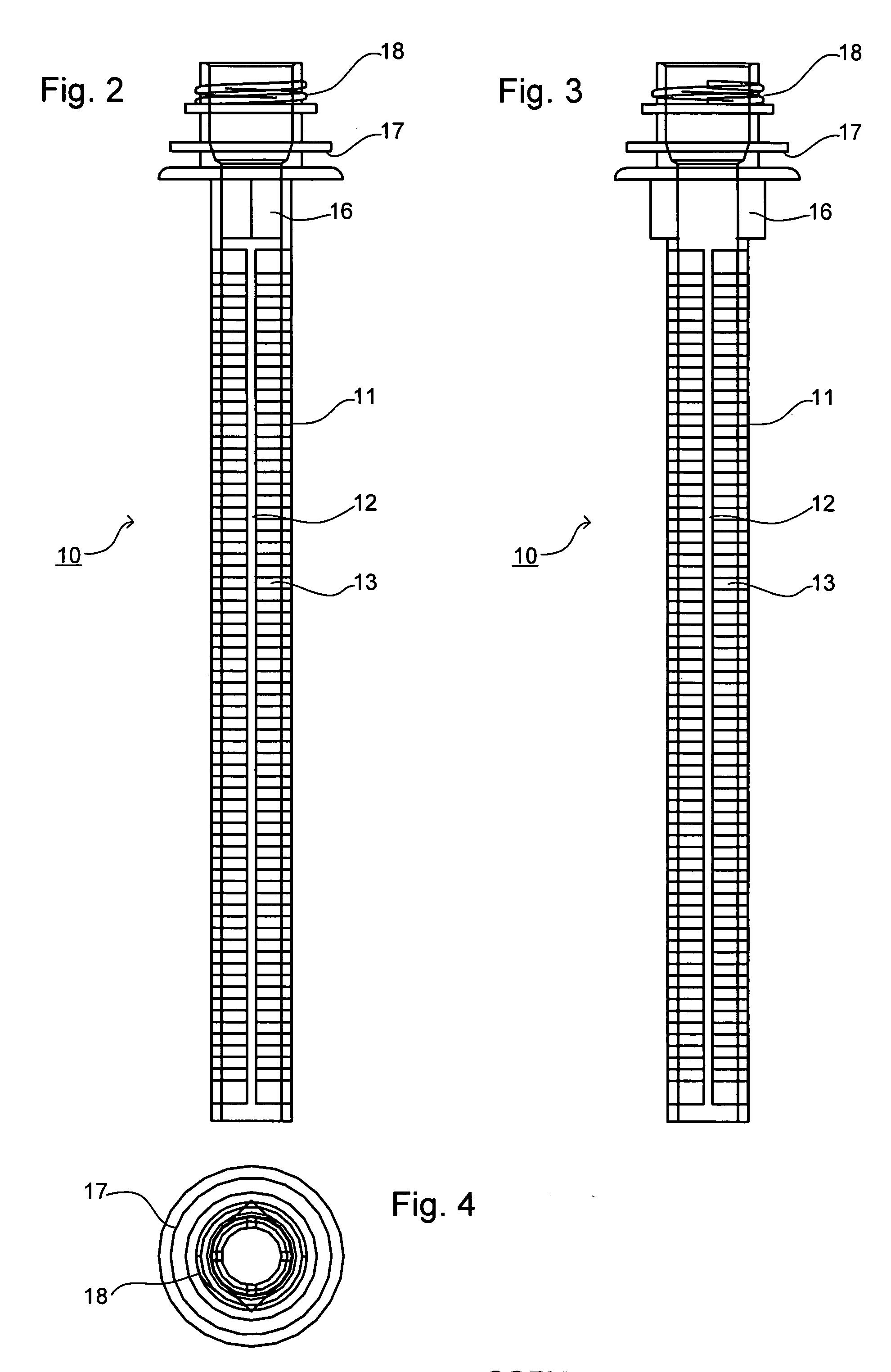

Image

Examples

examples

[0029] Ink samples of varying viscosity were filled into 1000 cc bag-in-box cartridges of identical design except that one group had a flow directing device according to the above described embodiment and a second group had a fitment according to GB-A-2 331 065. The cartridges were allowed to equilibrate overnight in a test environment with a temperature of 10° C. For each ink and fitment variation ink, depletion performance was assessed by carrying out printing tests using a Priport JP5500 digital duplicator (Ricoh Company of Japan). Printing was continued until an ‘out of ink’ signal was given by the printing machine. At this point the cartridge was weighed and the ink residue was calculated by subtracting the average weight for the cartridge packaging. A ‘Pass’ result was recorded when all 10 cartridges within a test group achieved a residue of 5% or less. Results are tabulated below to confirm the superior performance of the present invention.

Depletion Test ResultsFitment AsIn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com