Heat-resistant ironing board cover having an elastic padding

a technology elastic padding, which is applied in the field of ironing board cover, can solve the problems of removing such a cover, in particular its padding, from the ironing board for the purpose of replacement, and achieves the effect of simple and effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

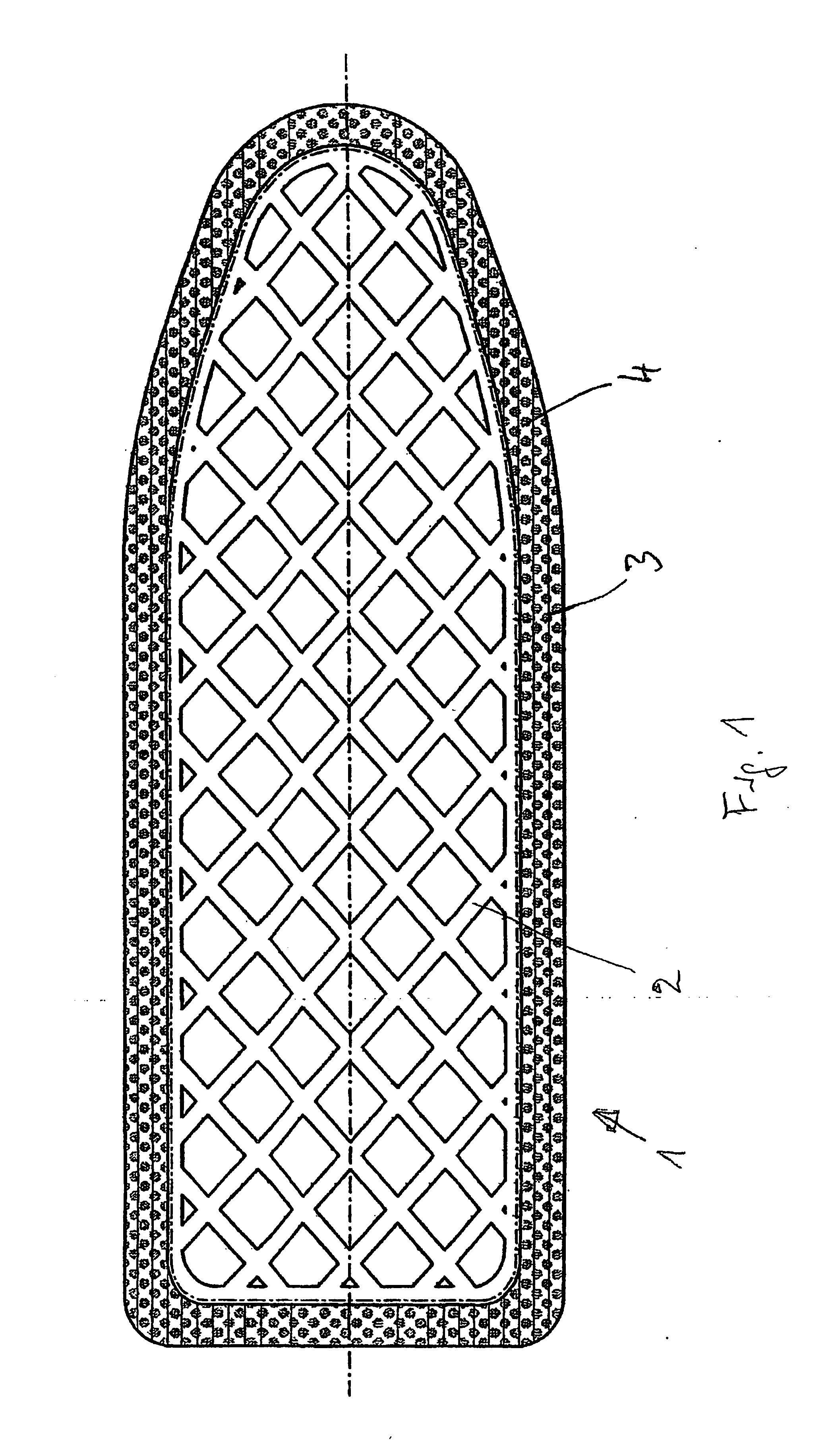

[0017]FIG. 1 shows the top view of an ironing board 1. Ironing board 1 has, as is known, a board surface 2 made of expanded metal. A nonwoven layer 4, whose top is provided with barbs for a hook-and-loop fastener, is glued around the entire edge 3 of board surface 2. The contour of padding 5 (see FIG. 2) of ironing board cover 6 is designed such that it corresponds to the contour of ironing board 1. In addition, its bottom 7 is also provided with a nonwoven layer 8, whose design corresponds to nonwoven layer 8 on top face 9 of ironing board 1. However, this nonwoven layer 4 is provided with loops, so that the hooks of nonwoven layer 4 of the ironing board may engage with them.

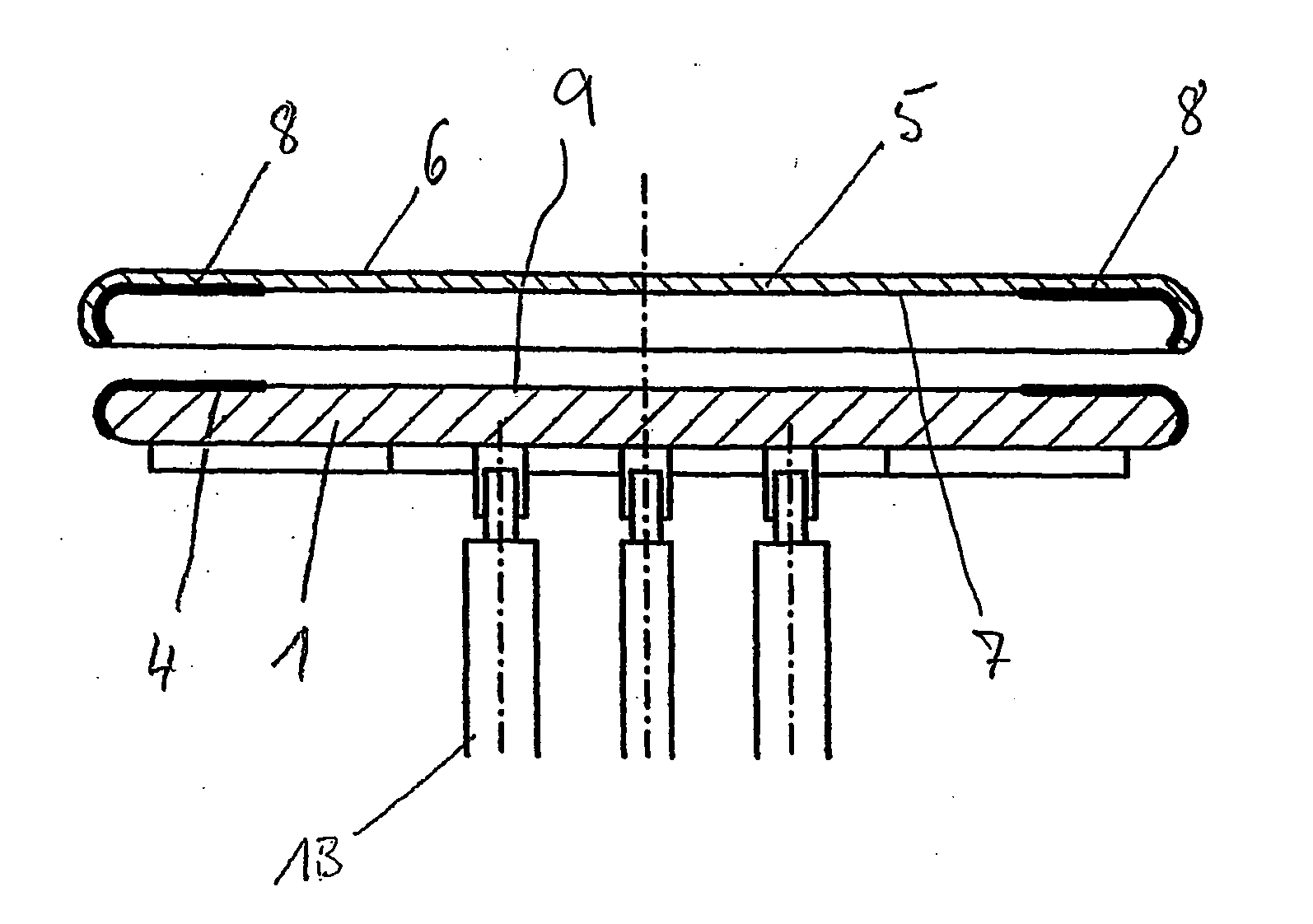

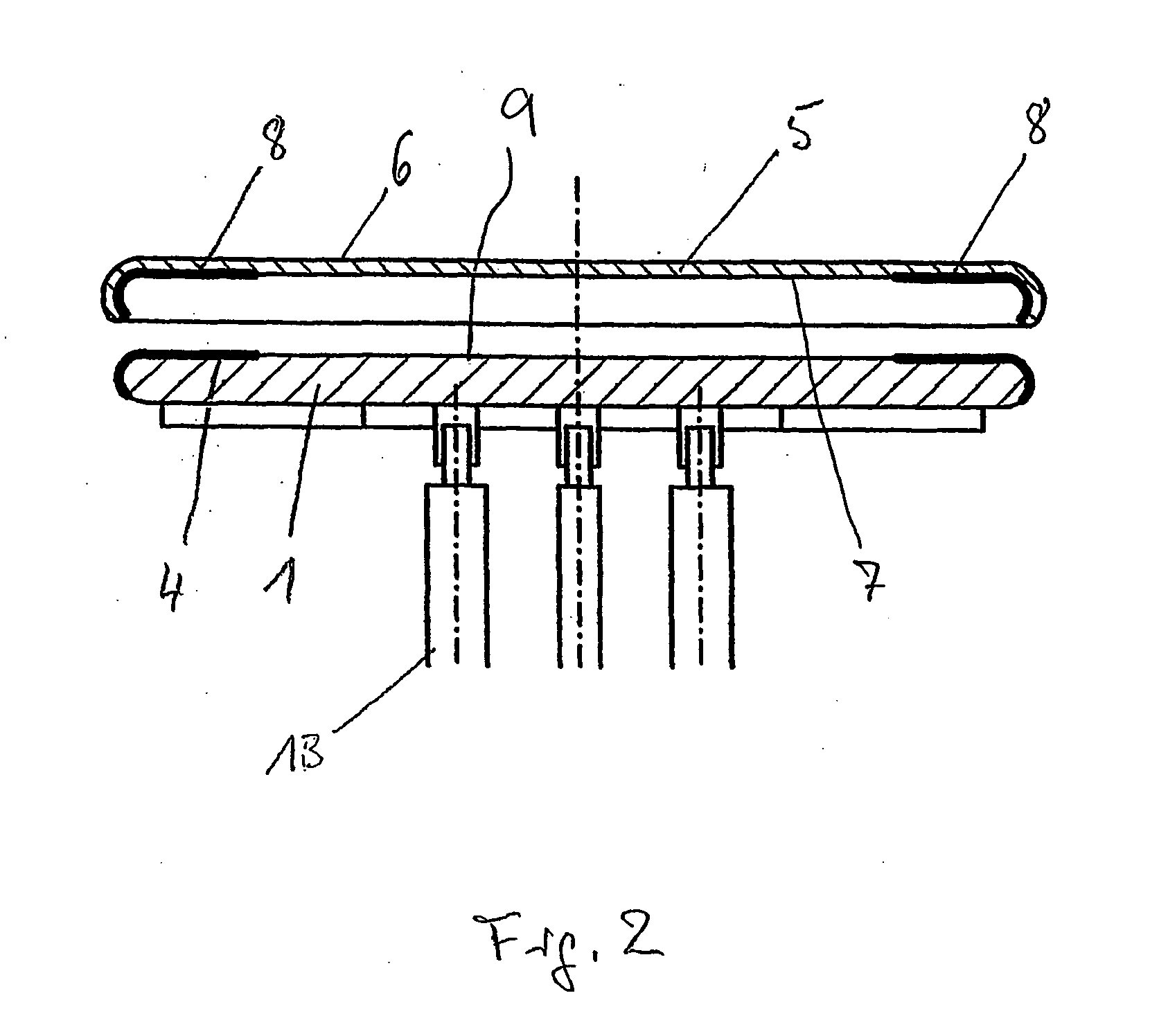

[0018]FIG. 2 shows the individual parts in an exploded view. After ironing board cover 6 is placed on ironing board 1 and pressed by hand, a sufficiently strong connection is produced between ironing board cover 6 and ironing board 1. It should also be noted that only legs 10 are indicated under the ironing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com