Sheet reversing apparatus and image forming apparatus

a technology of image forming apparatus and reversing sheet, which is applied in the directions of transportation and packaging, thin material processing, article delivery, etc., can solve the problems of difficult improvement of both-side printing process productivity, waste of time, and longer time required for a longer sheet, so as to reduce the time required for reversing and improve the productivity of both-side image forming process, the effect of avoiding deterioration of print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

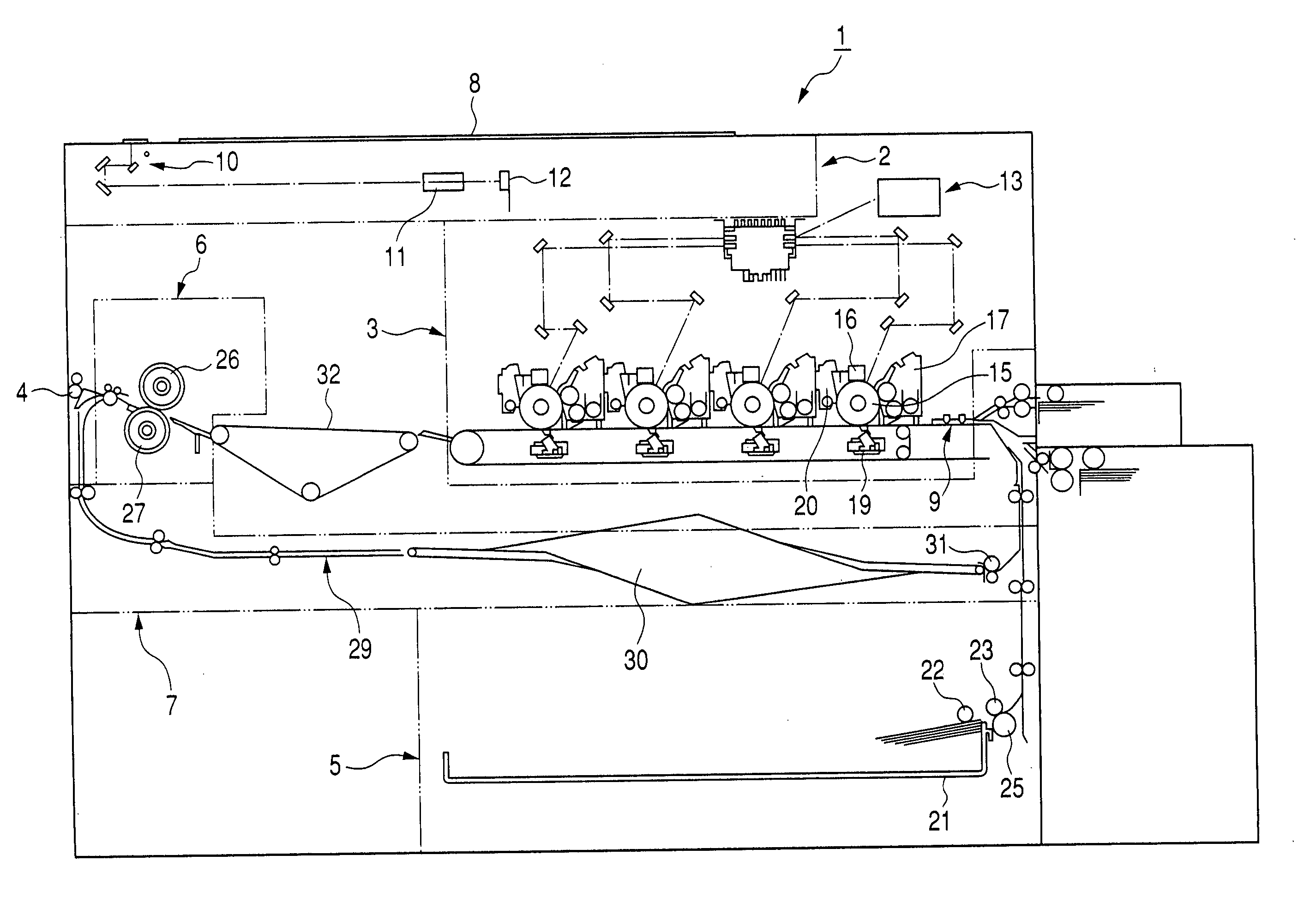

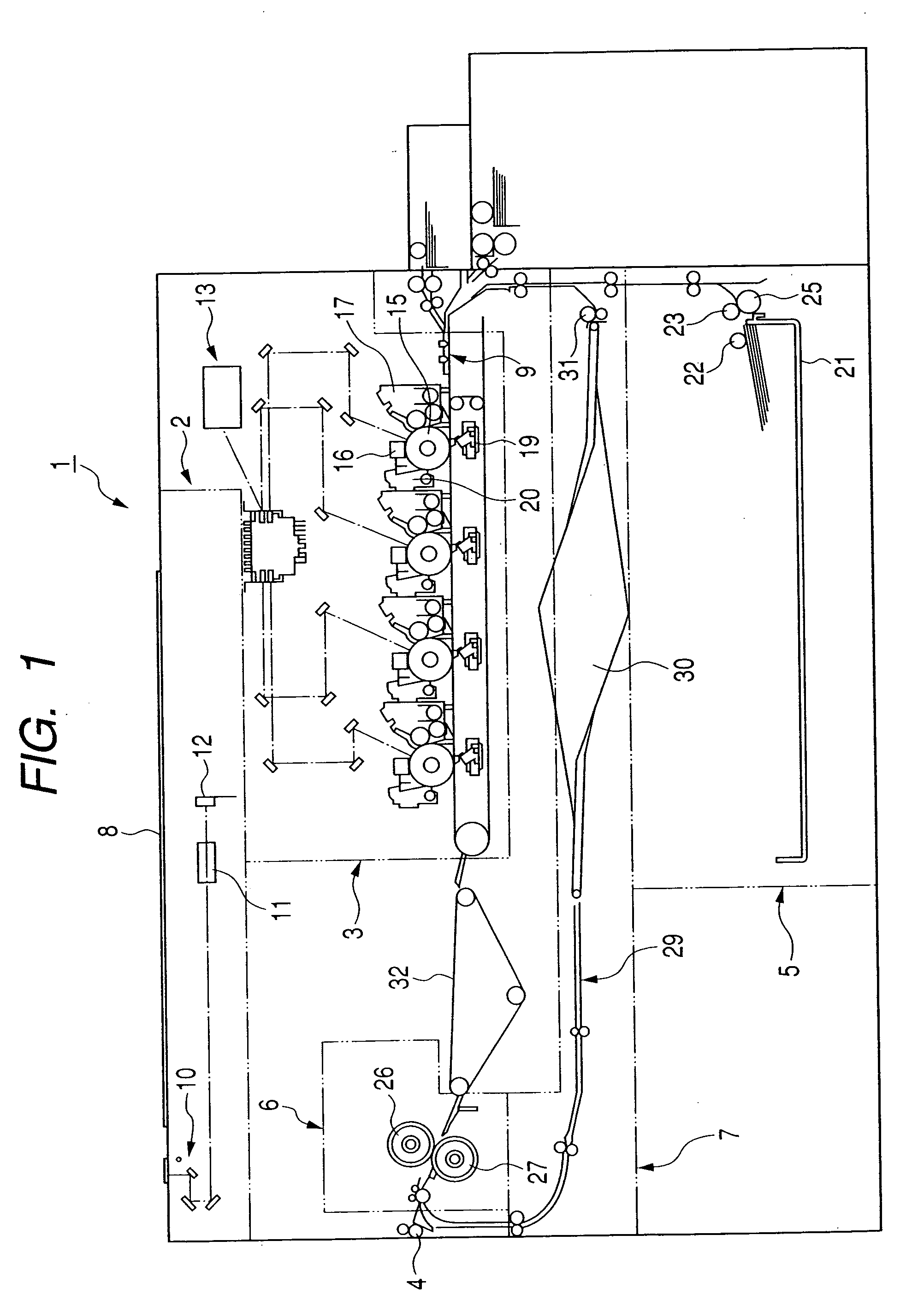

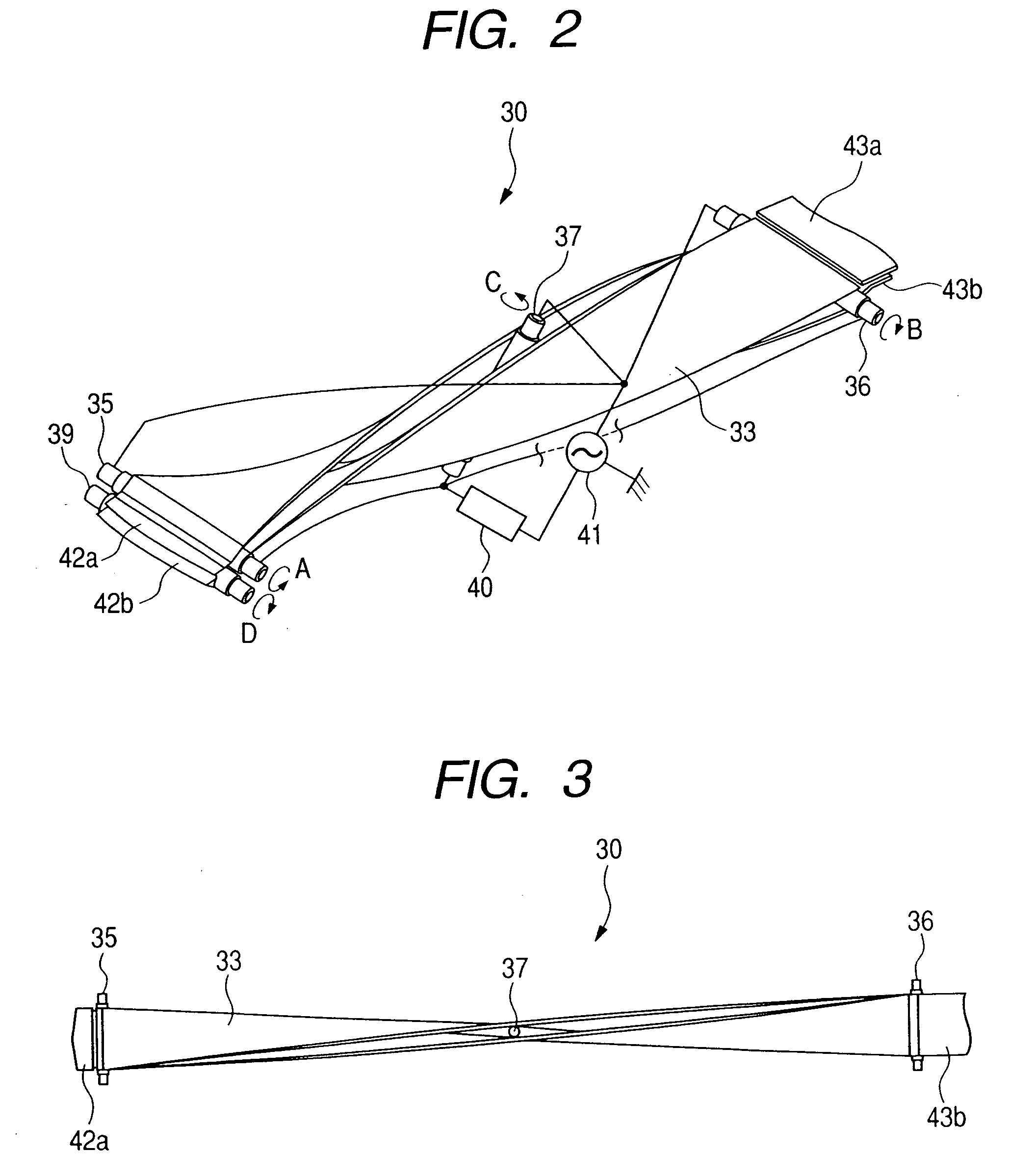

[0033] In the following, a sheet reversing apparatus and an image forming apparatus embodying the present invention will be explained with reference to FIGS. 1 to 8.

[0034]FIG. 1 is a lateral cross-sectional view of an image forming apparatus embodying the present invention; FIG. 2 is a perspective view of a sheet reversing apparatus of the present invention as a reversing unit; FIG. 3 is a plan view of a reversing unit embodying the present invention; FIG. 4 is a lateral view of a reversing unit embodying the present invention; FIG. 5 is a lateral view showing a conveying start position in the reversing unit embodying the present invention; FIG. 6 is a lateral view showing a conveying end position in the reversing unit embodying the present invention; FIG. 7 is a lateral view showing another sheet separating method from an attraction belt 33 of the embodiment; and FIG. 8 is a perspective of the reversing unit of the embodiment in the course of sheet conveying.

[0035] The image form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com