Reciprocating compressor

a compressor and reciprocating technology, applied in the direction of positive displacement liquid engines, pumps, machines/engines, etc., can solve the problems of deteriorating motor performance, and achieve the effect of reducing the width of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A first embodiment of the present invention will now be described with reference to the accompanying drawings.

[0036] There can be a plurality of embodiments of the reciprocating compressor in accordance with the present invention, and a preferred embodiment will now be described.

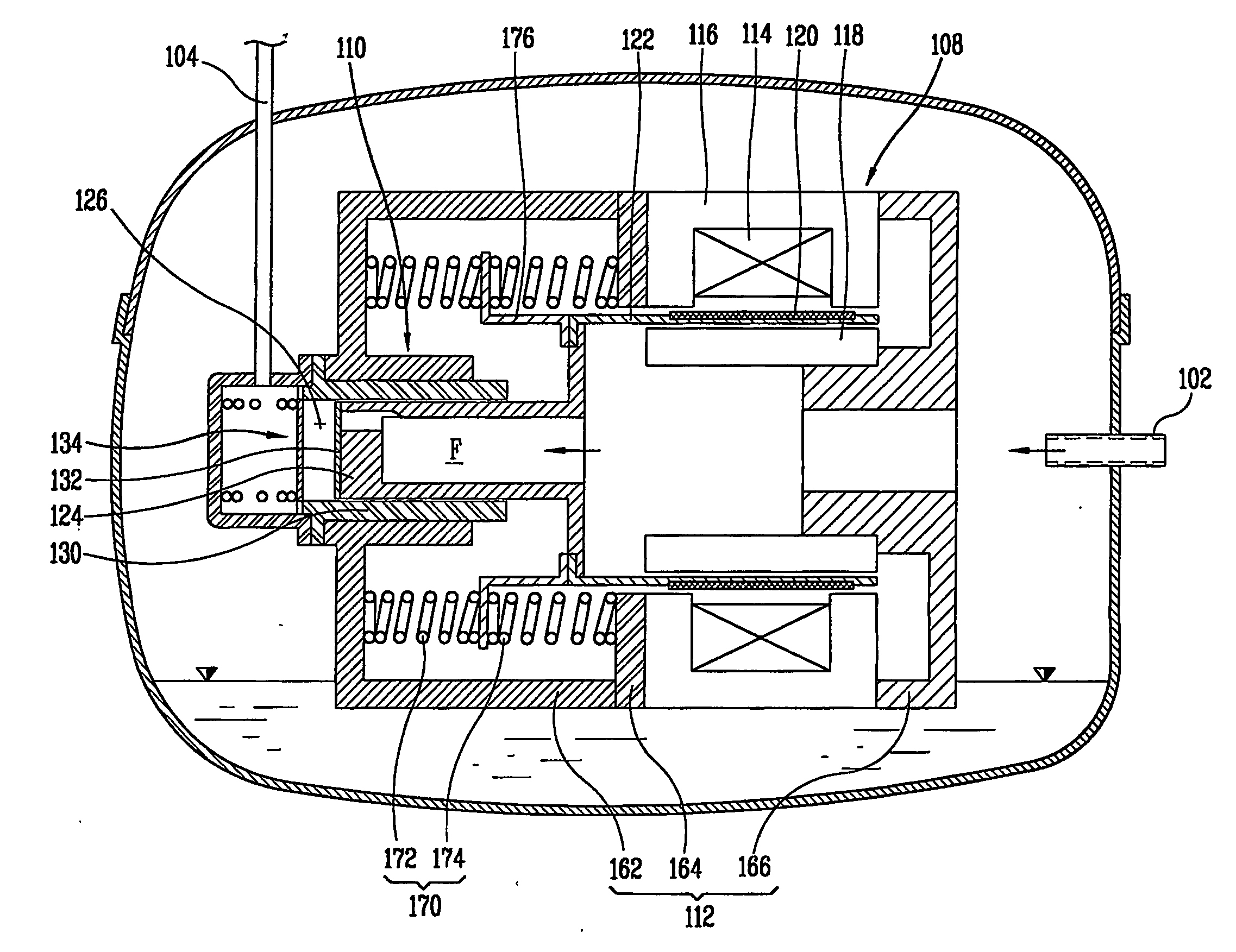

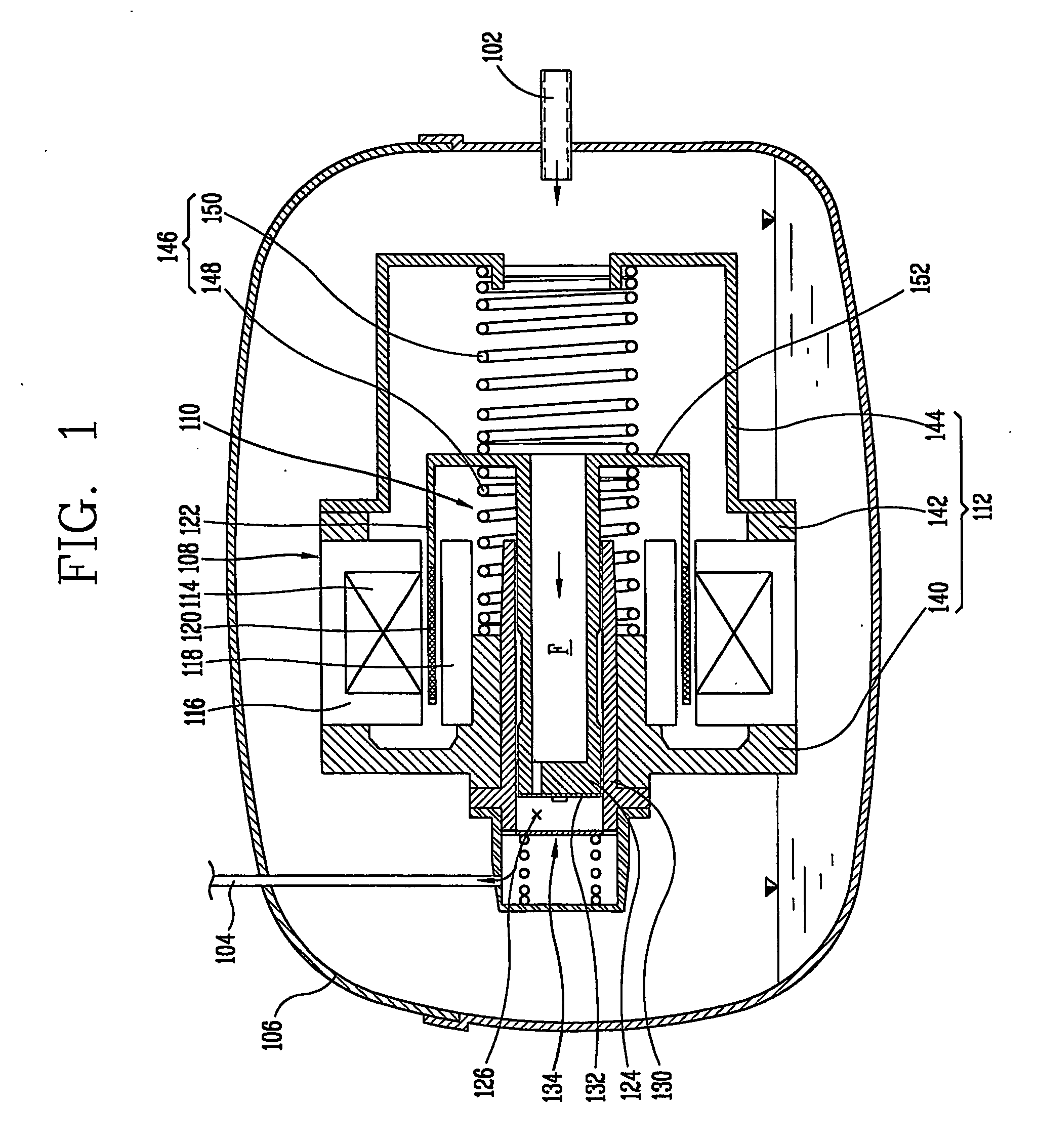

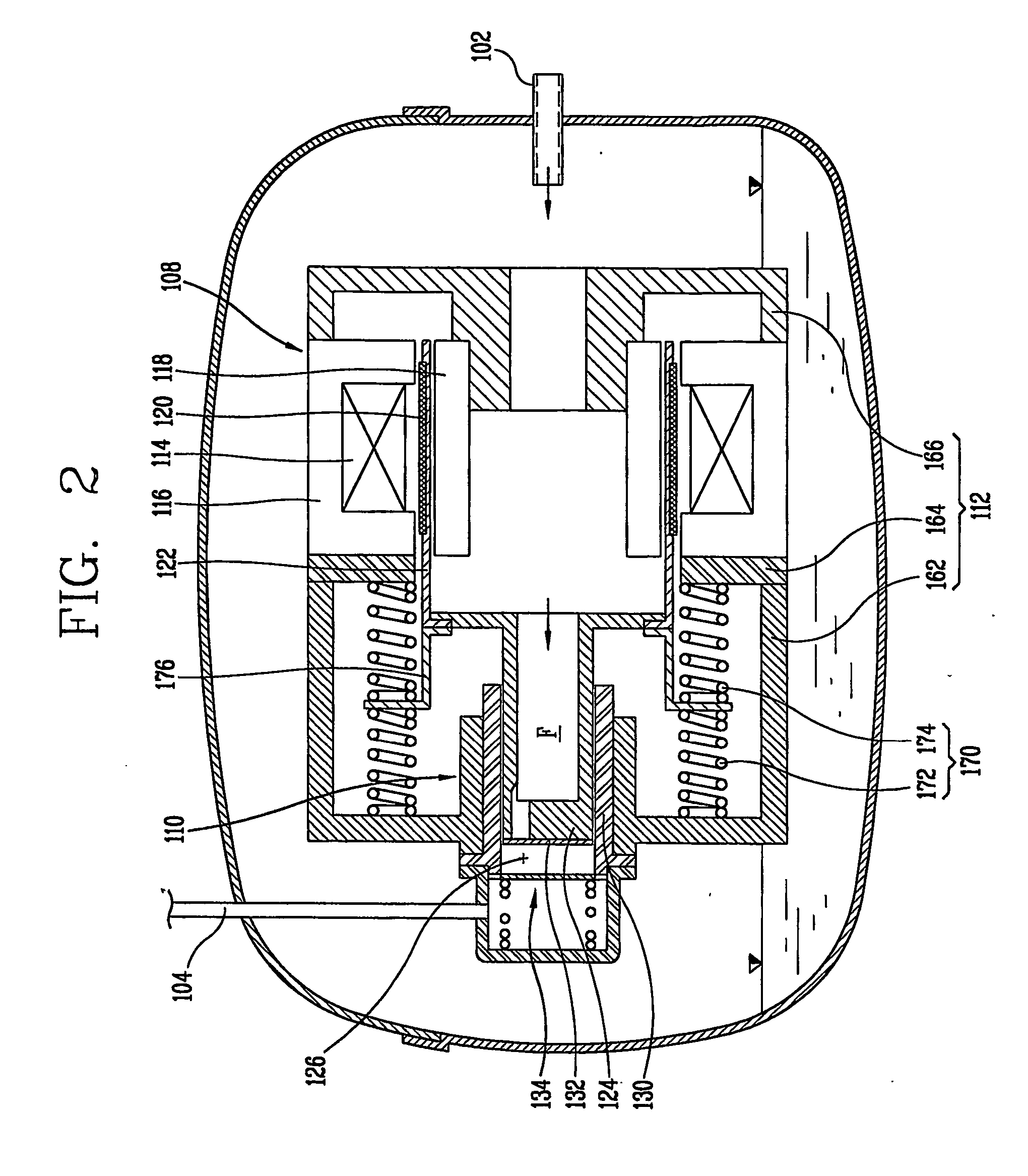

[0037]FIG. 3 is a sectional view of a reciprocating compressor according to the present invention.

[0038] The reciprocating compressor of the present invention includes a casing 14 to which a suction pipe 10 and a discharge pipe 12 are connected respectively; a driving unit 16 disposed in the casing 14 and generating a reciprocal movement force; a compression unit 18 disposed in the driving unit 16 and compressing a fluid by being transmitted the reciprocal movement force of the driving unit 16; a support unit 20 supporting the driving unit 16 and the compression unit 18; a resonant spring assembly 24 installed at the support unit 20 and inducing a resonant movement of the piston 22 by providing an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com