Device and system for modified atmosphere packaging

a technology of gassing apparatus and modified atmosphere, which is applied in the direction of special packaging, packaging, and special atmospheric conditions, etc., can solve the problems of limited shelf life of goods, limited space available for gassing operations, and air removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

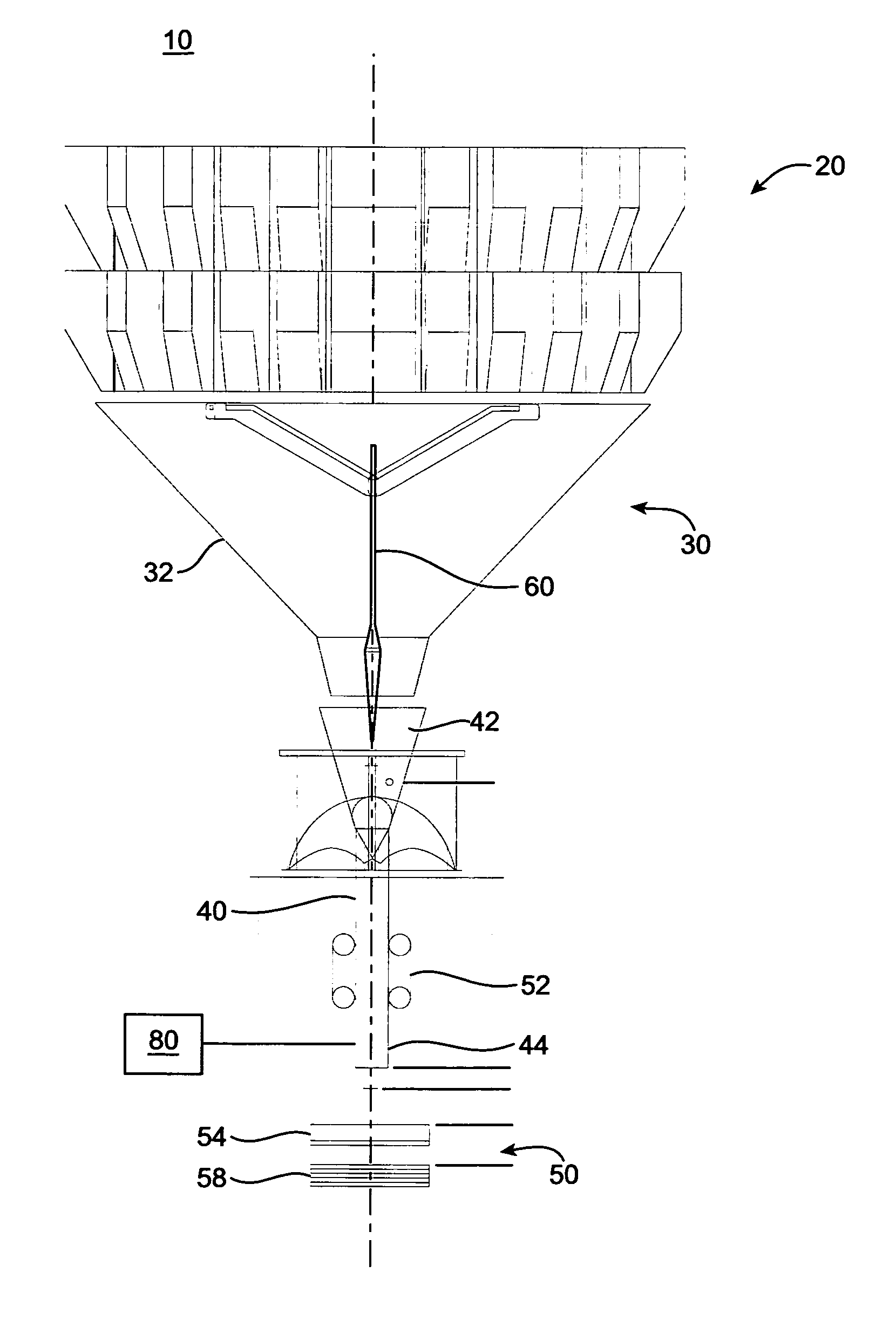

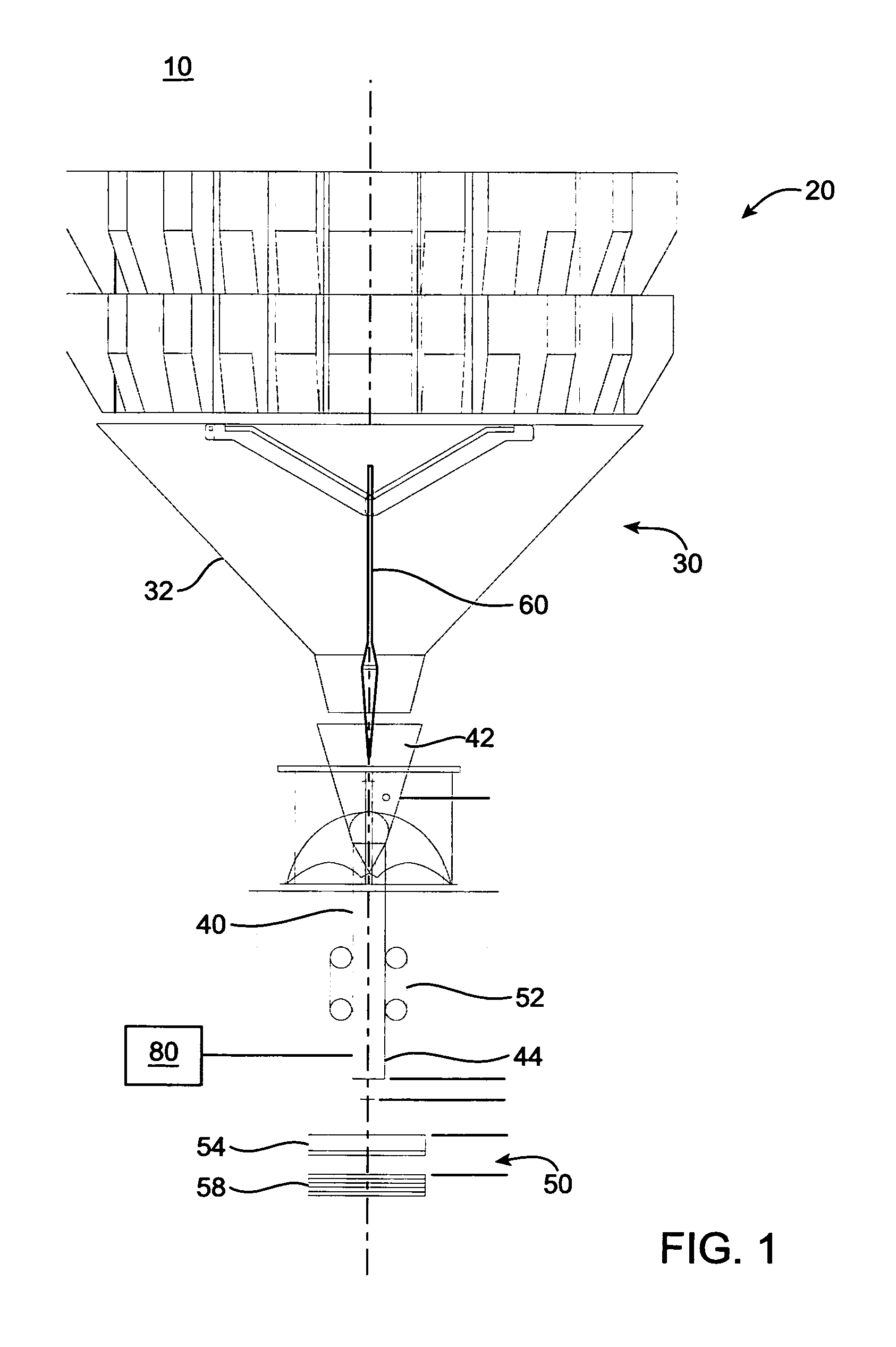

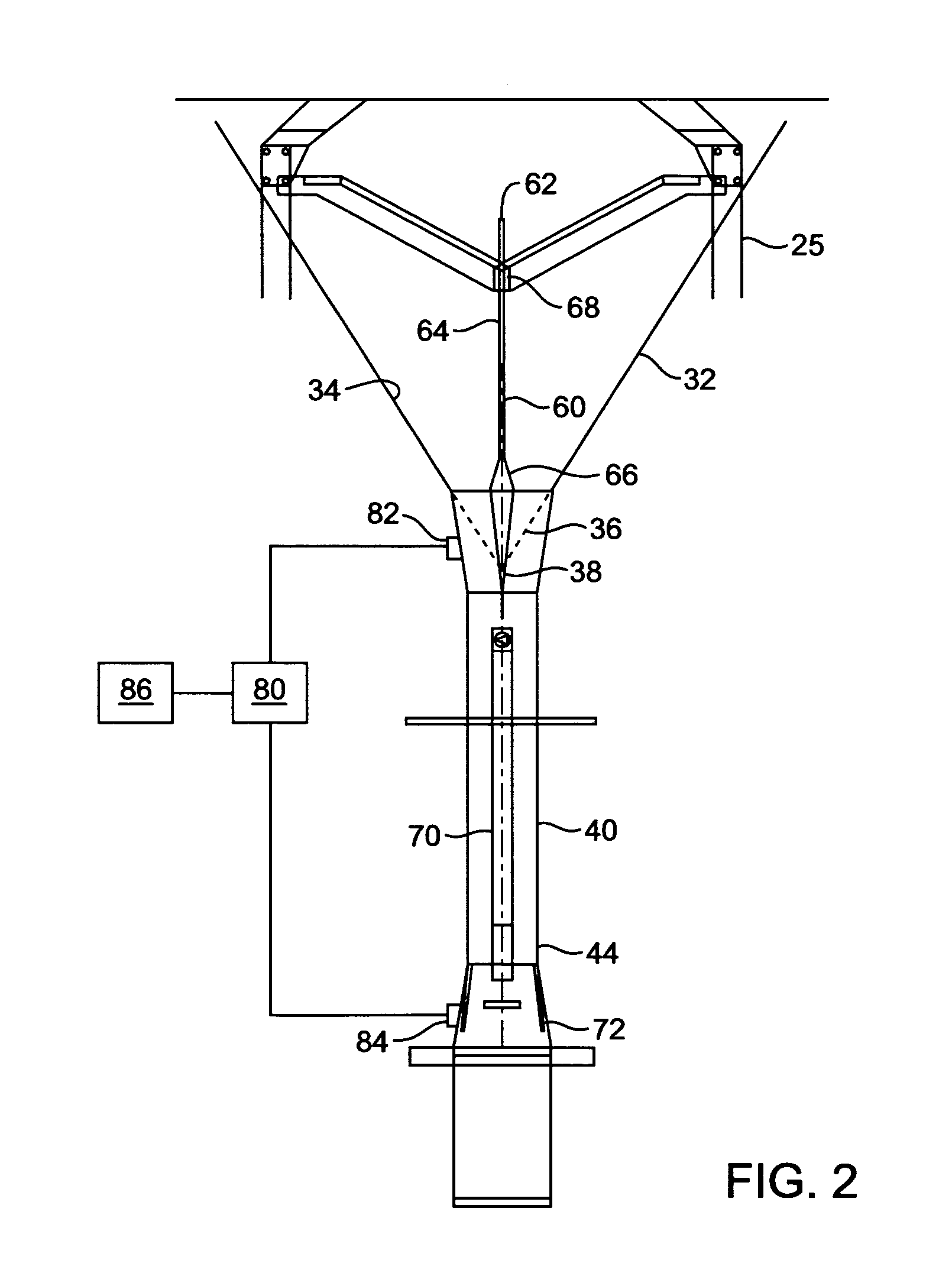

[0020]FIG. 1 is an illustrative packaging system 10 for a gassing apparatus made in accordance with the present invention. The packaging system 10 includes a plurality of weighing buckets 20, a hopper assembly 30, a filling tube 40, a packaging assembly 50 and a gassing controller 80. The packaging system 10 further includes a gassing assembly, described in more detail below.

[0021] The hopper assembly 30 includes a hopper 32 for receiving product from at least one of the plurality of weighing buckets 20 and bracket 34 (FIG. 2). Hopper 32 comprises a funnel or cone shaped receptacle as are well known in the art. Hopper 32 tapers towards filling tube 40. Filling tube 40 includes a funnel shaped upper end 42 for receiving product from hopper 32 and a lower end 44 where product exits into a formed package (not shown). The packaging assembly 50 includes film rollers 52, product stager 54 and seal jaw 56. Packaging assembly 50 may include other components for forming and filling a packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com