Base coupling structure of a height adjustable chair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

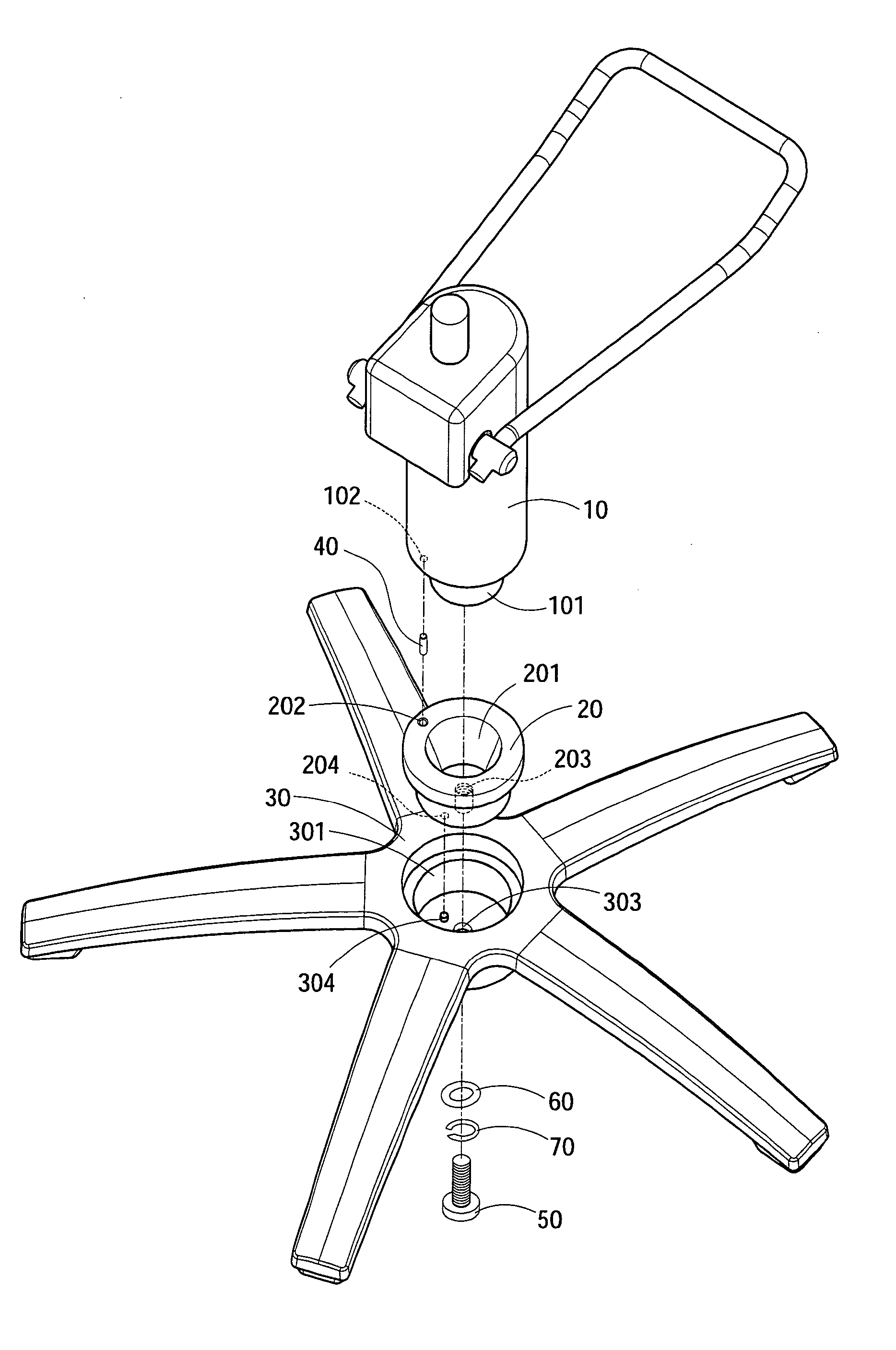

[0013] Please refer to FIGS. 3 and 4. The base coupling structure of a height adjustable chair of the present invention comprises an oil cylinder 10, a sleeve 20 and a foot support 30. The bottom of the oil cylinder 10 has a connecting post 101 and such connecting post 101 has a taper. The sleeve 20 having a receiving hole 201 which has a larger outer circumference and a smaller inner circumference. And the size of the receiving hole 201 corresponds to the size of the connecting post 101 of the oil cylinder 10, so that the largest aperture of the receiving hole 201 is slightly bigger than the connecting post 101 and the smallest aperture of the receiving hole 201 is slightly smaller than the connecting post 101. Thus, the connecting post 101 of the oil cylinder 10 can be tightly embedded into the receiving hole 201 of the sleeve 20 by taking the advantages of having slightly different taper sizes and different elasticity of materials. The oil cylinder 10 can be tightly embedded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com