Wetsuit Hanger Dryer

a wetsuit and dryer technology, applied in the field of wetsuit hanger dryers, can solve problems such as achieve the effects of accelerating the drying process, reducing the length of time, and increasing the frequency of wetsuit utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

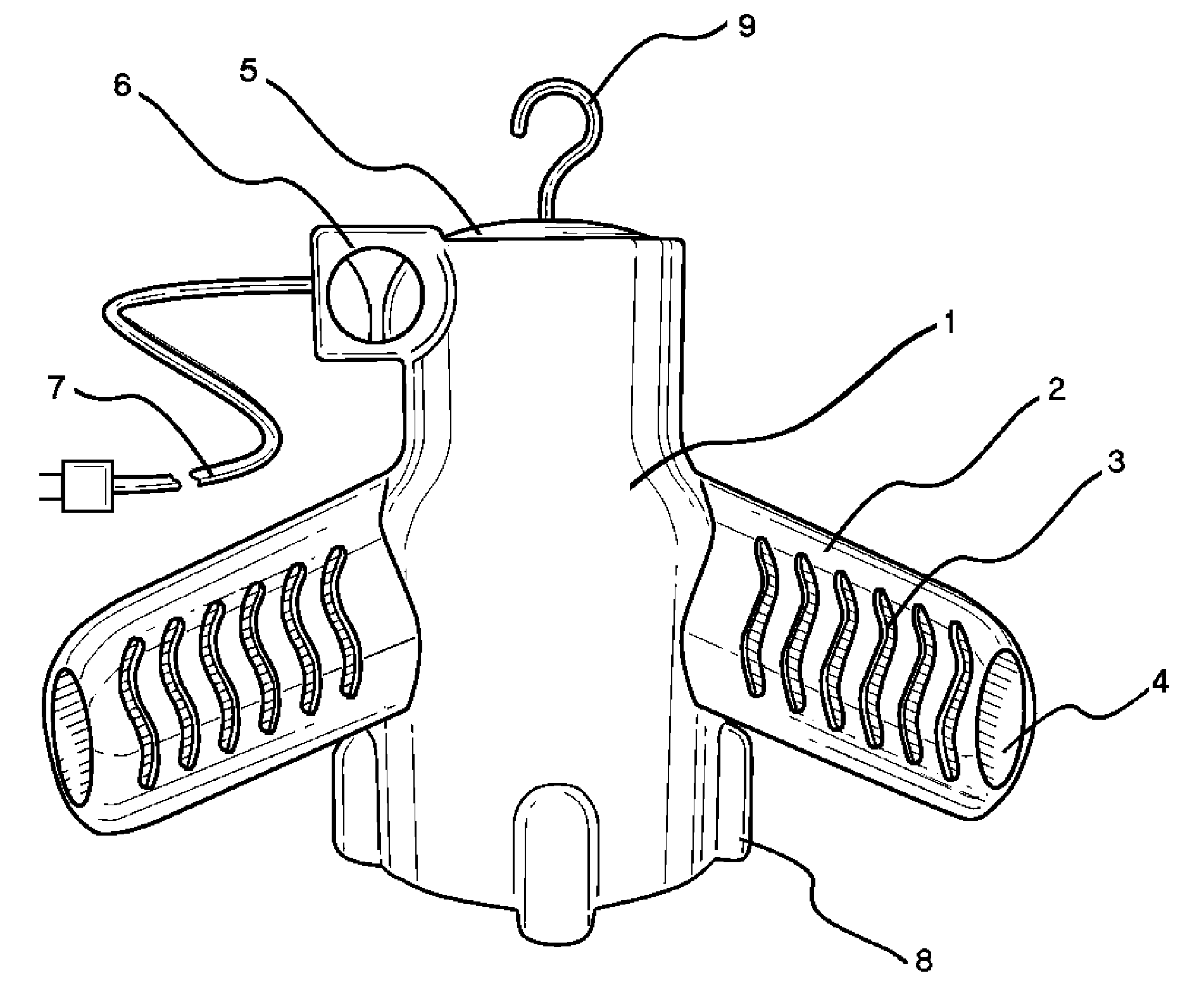

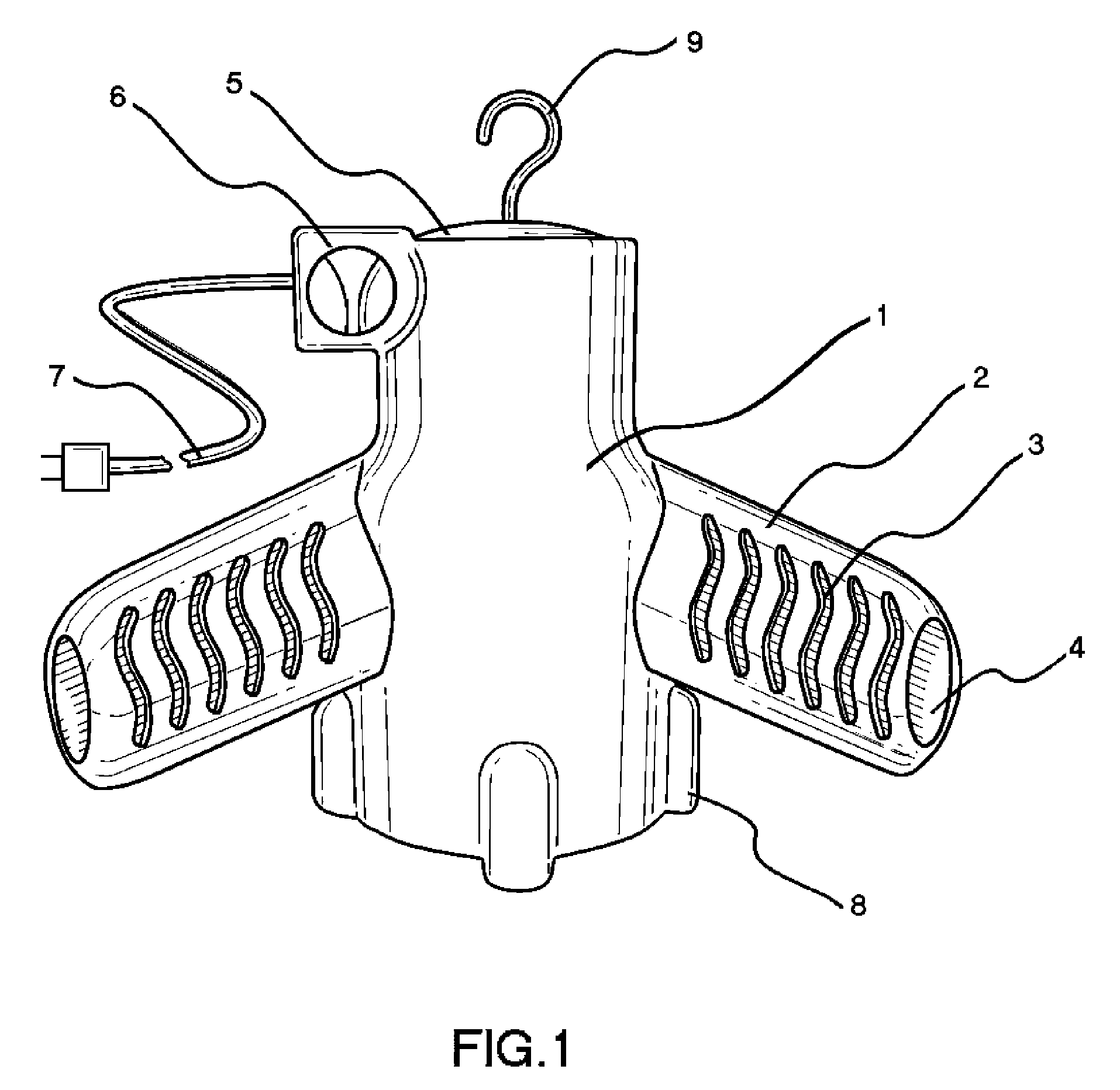

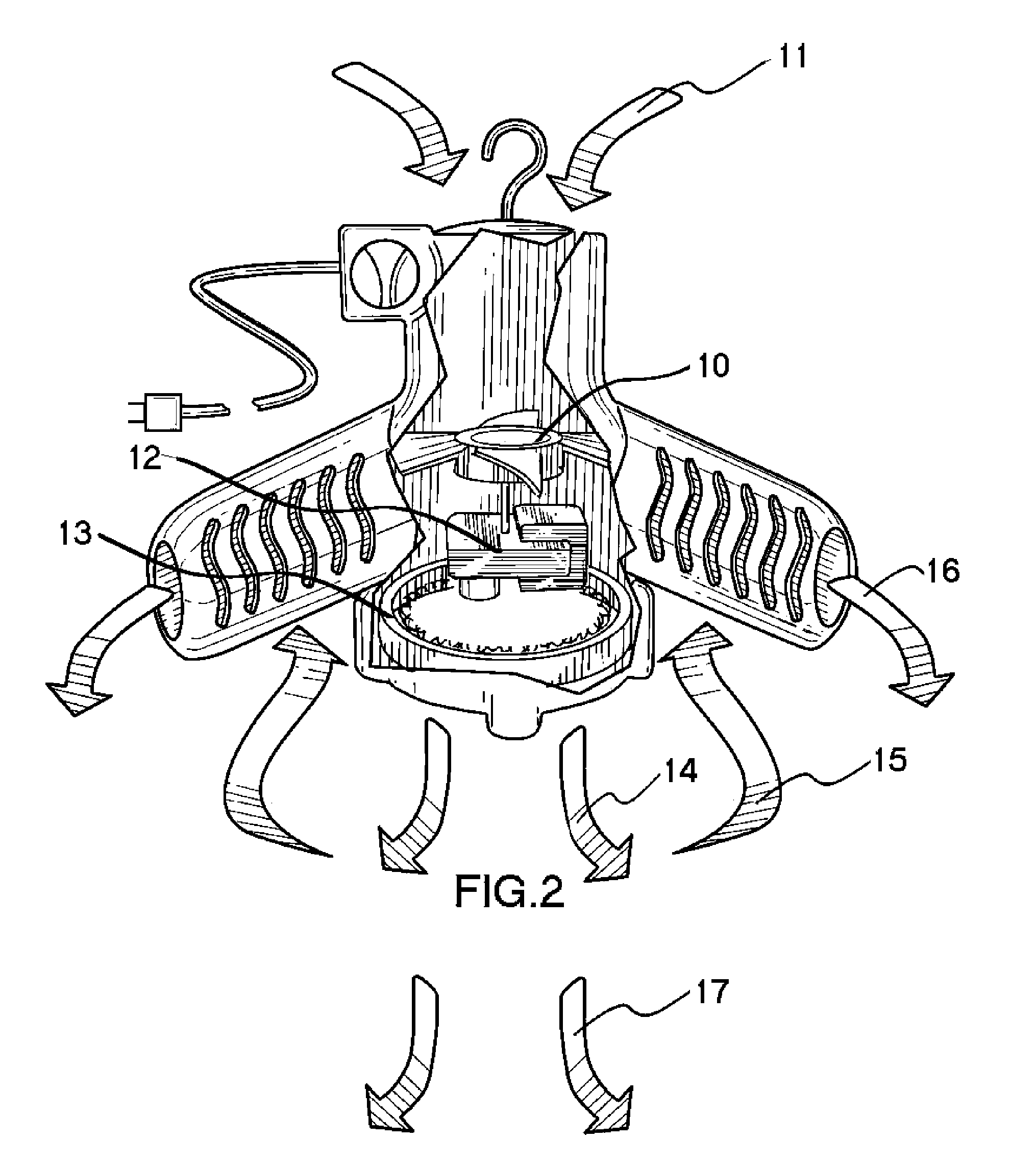

[0011]FIGS. 1-4 illustrate one preferred embodiment of the invention. As illustrated in FIG. 3, the embodiment provides a hanger / dryer system 1 and 2 for more safely hanging while greatly accelerating the drying of a wet wetsuit 18.

[0012]FIG. 1 is a front perspective view of the hanger / dryer system showing the body of the unit 1, which contains the drying components and its integral hanger arms 2. The arms' broad, contoured surfaces minimize stress on the wetsuit shoulders when hanging on the system. Slots 3 and openings in the underside of the arms 2 allow air to circulate freely into the wetsuits' shoulder region and then out of the hanger armholes 4 and exiting the wetsuit's sleeves. The domed air grill 5 allows air to be drawn into the body 1 for warming before it is pumped into the wetsuit itself. The timer switch 6 permits selective, safe and pre-timed use of the system. The power cord 7 provides standard 110-volt power to the system. Foot supports 8 provide a stable resting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com