Brush with stapled tufts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

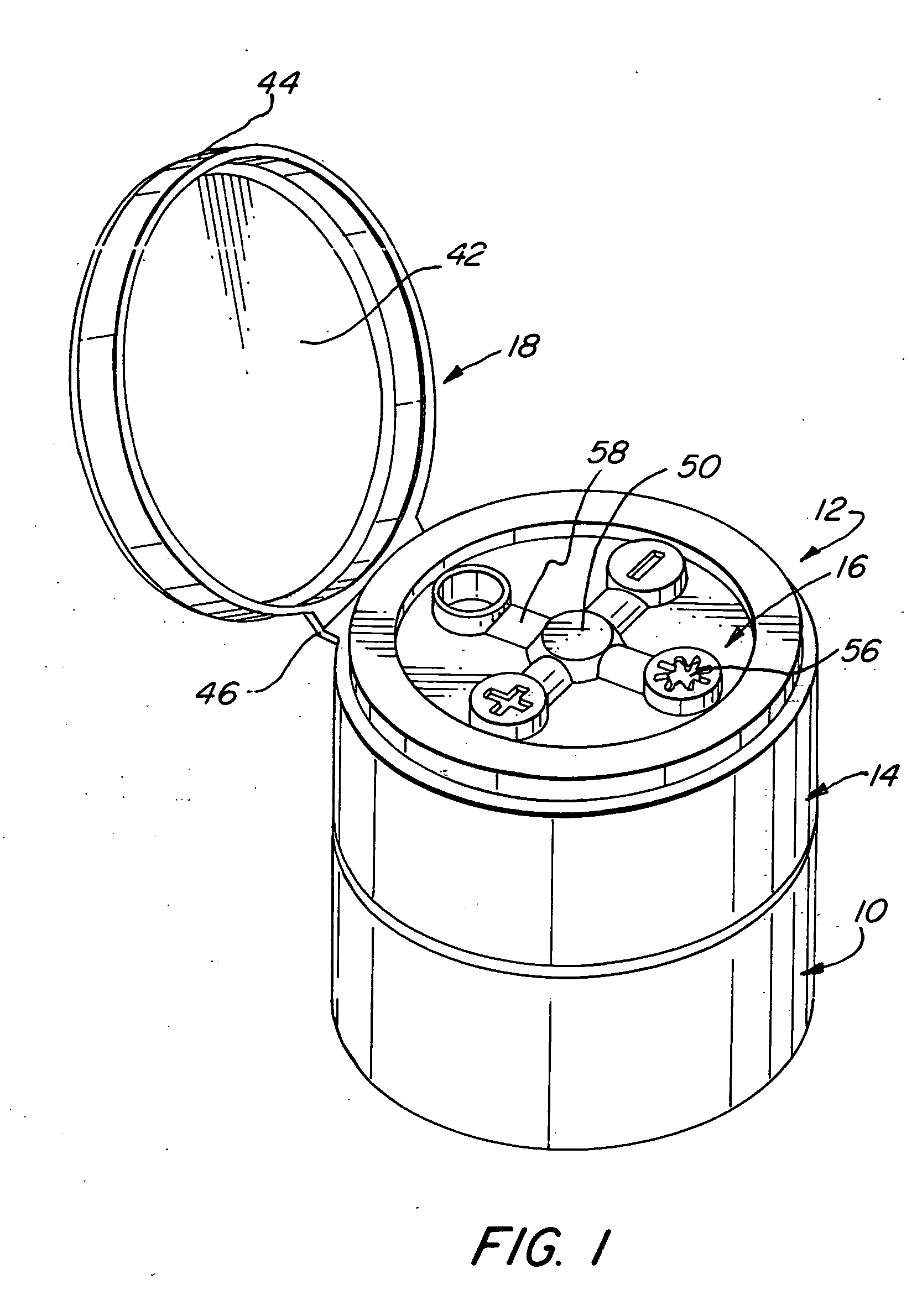

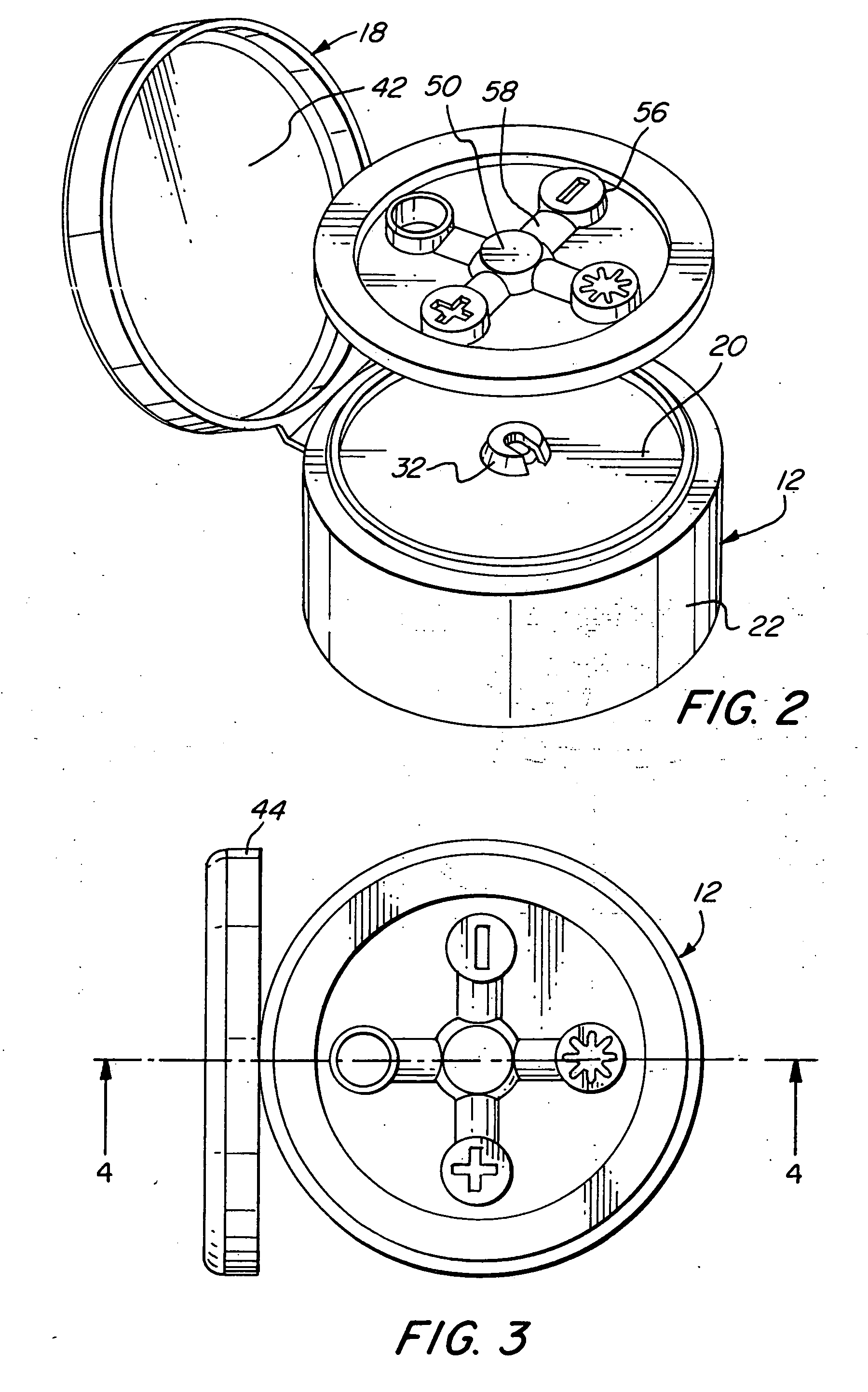

[0018] Turning first to FIG. 1, therein shown is a tooth brush employing the present invention and comprising a head 10 and a handle or grip 12. Seated in recesses (seen in FIGS. 4 and 5) in the head 10 are tufts generally designated by the numeral 14 and comprised of a multiplicity of bristles 16.

[0019] Turning next to FIGS. 2-4, therein illustrated is a staple embodying the present invention and generally designated by the numeral 18. The coil 20 of staple wire is cut into short segments to provide the staple 18 which has a body portion 22 of generally rectangular cross section with semi-cylindrical ribs 24 on both side surfaces thereof. The semi-cylindrical ribs 24 are spaced apart on centers a distance X and have a diameter Y at their base which is less than the thickness Z of the body portion as best seen in FIG. 6.

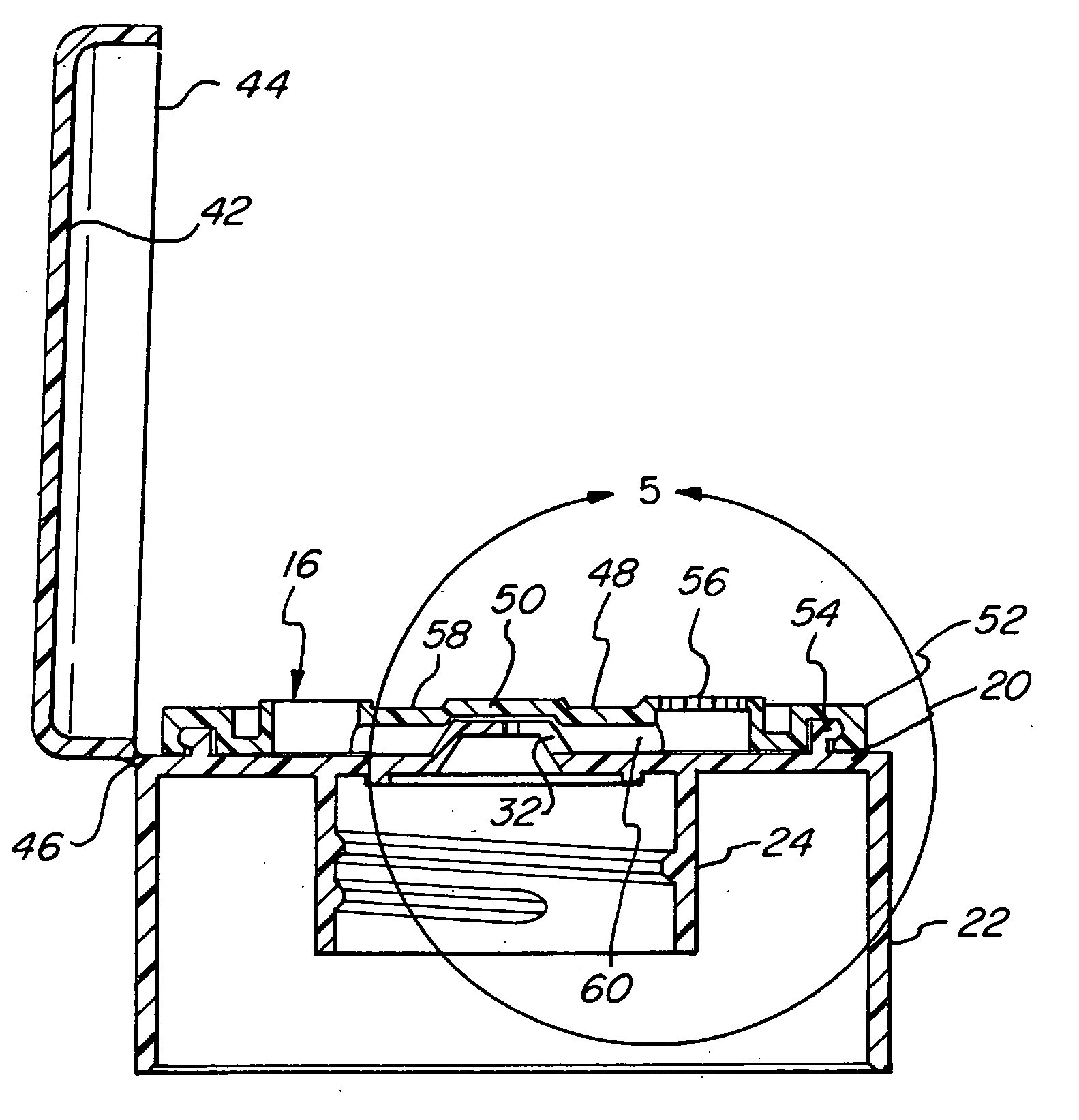

[0020]FIGS. 4 and 5 illustrate diagrammatically the method of assembling the tufts and staple into the brush head 10 which has a multiplicity of cylindrical recess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com