Dispensing container having improved torque response and closure sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

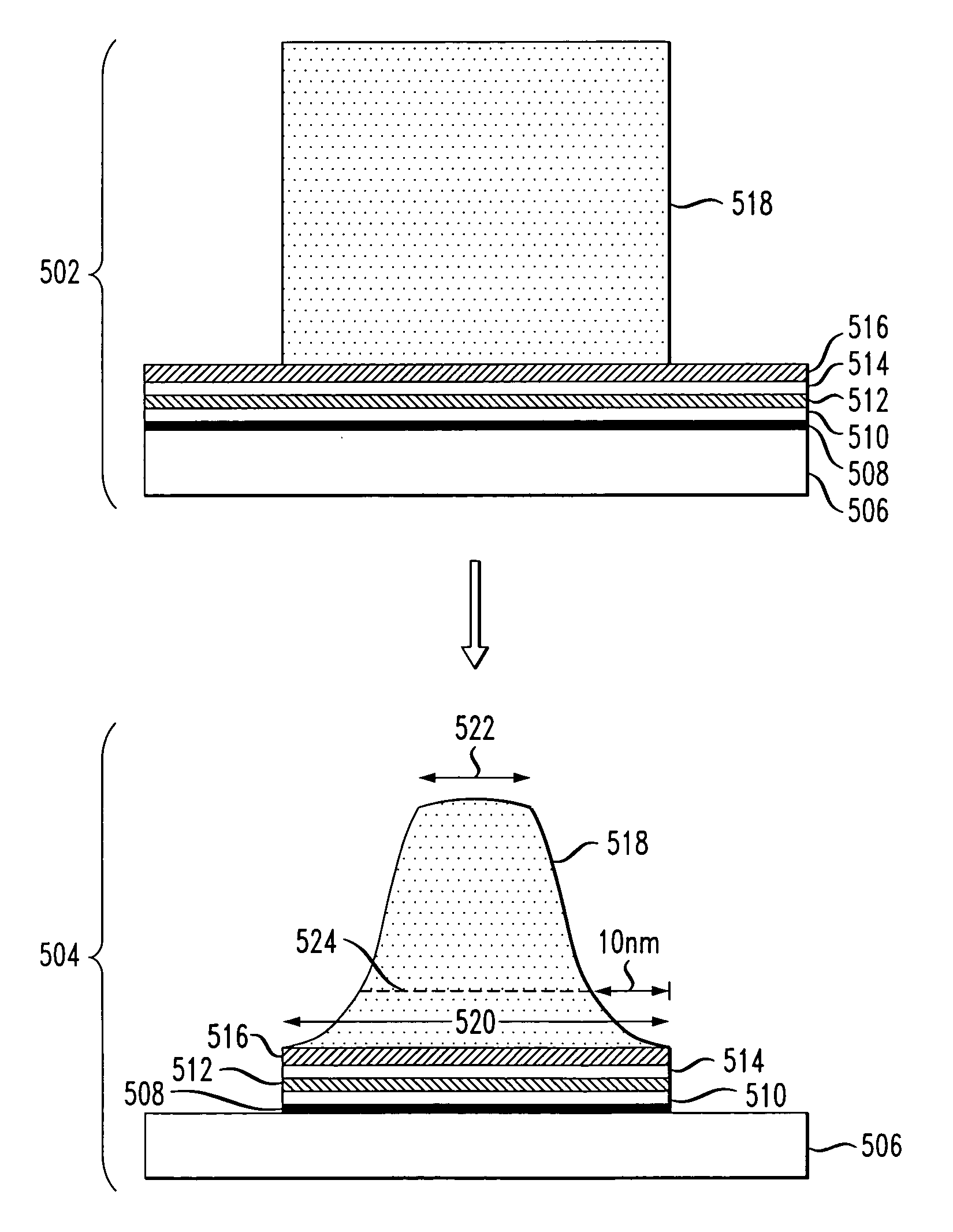

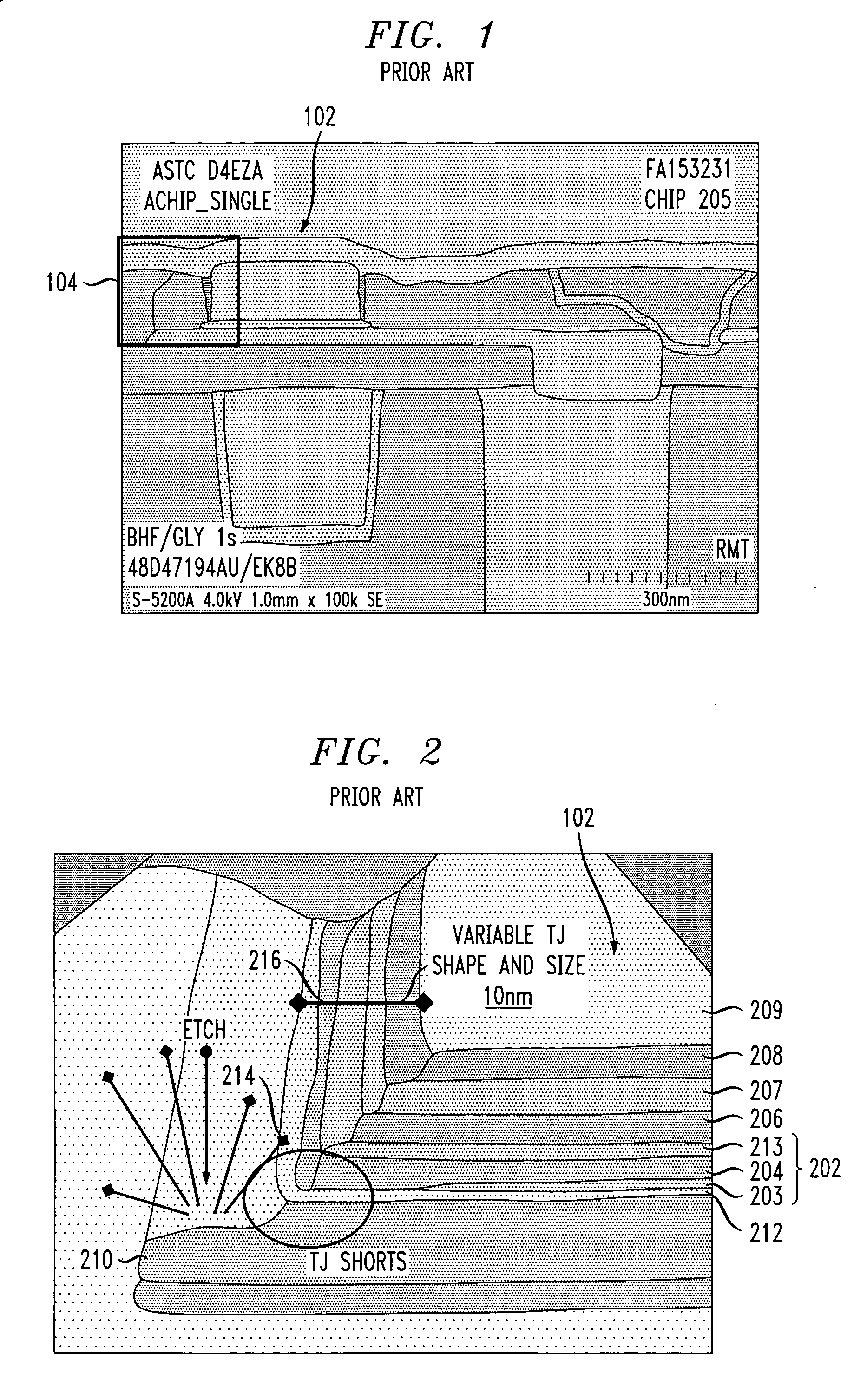

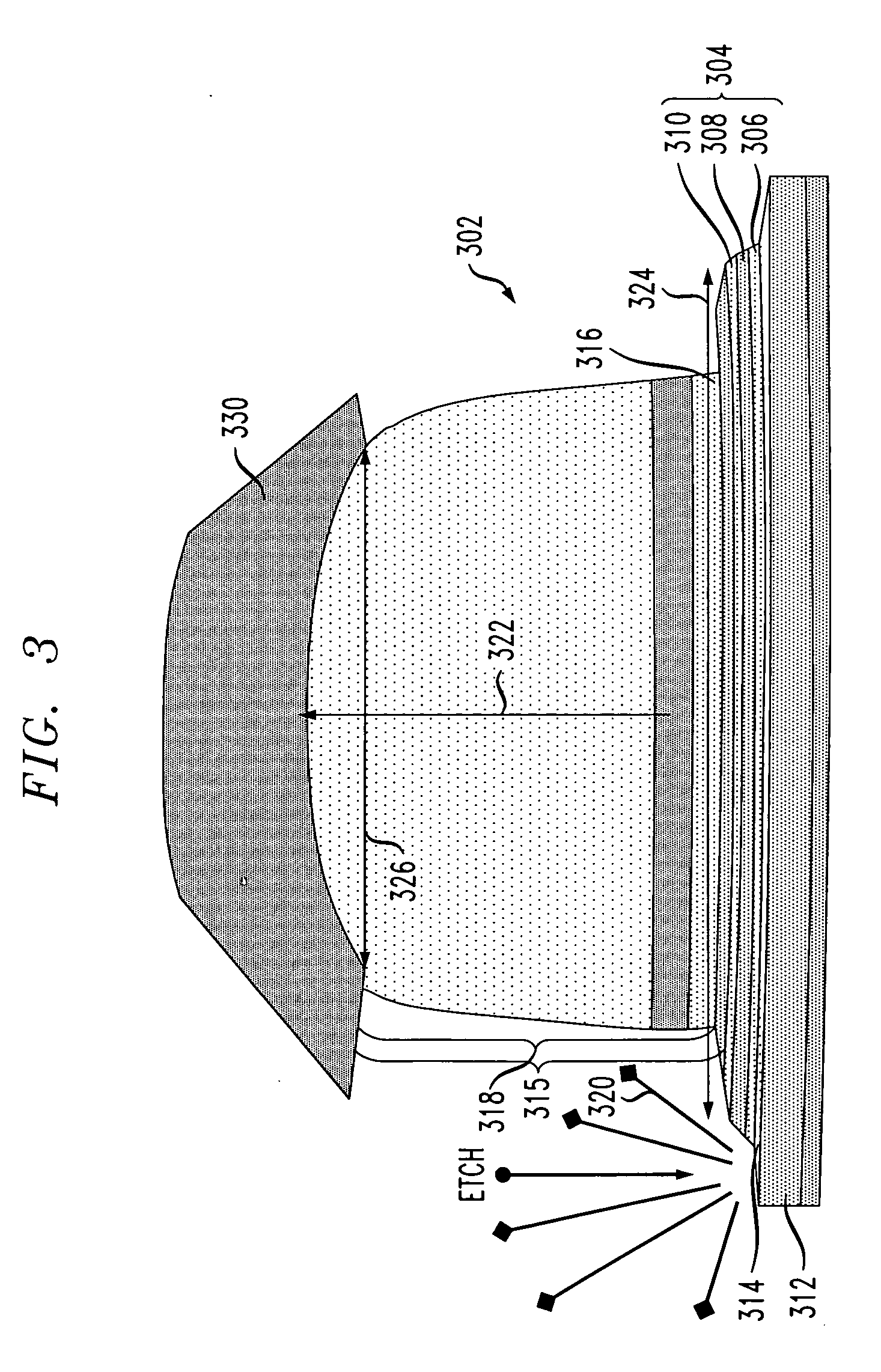

[0014] The dispensing tube of the present invention provides improved torque retention and response and closure sealing. The dispensing tube has a tapered surface within an indentation in the head that is adapted to receive and contact the leading edge of a closure. The tapered surface diminishes excessive torque generated when the closure is screwed onto the neck of the head.

[0015] The tapered surface is present within an indentation that extends into the head proximal to the junction of the neck and the shoulder and that extends circumferentially around the neck. The tapered surface tapers or slopes outward with respect to the neck (away from the neck) towards a top surface of the shoulder.

[0016] The taper or slope of the tapered surface enables the leading edge of the skirt of the closure to be easily received yet simultaneously be contained, constrained, or blocked as the closure is screwed on to the neck and head. Since the tapered edge is tapered inward toward the neck, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com