Anchoring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

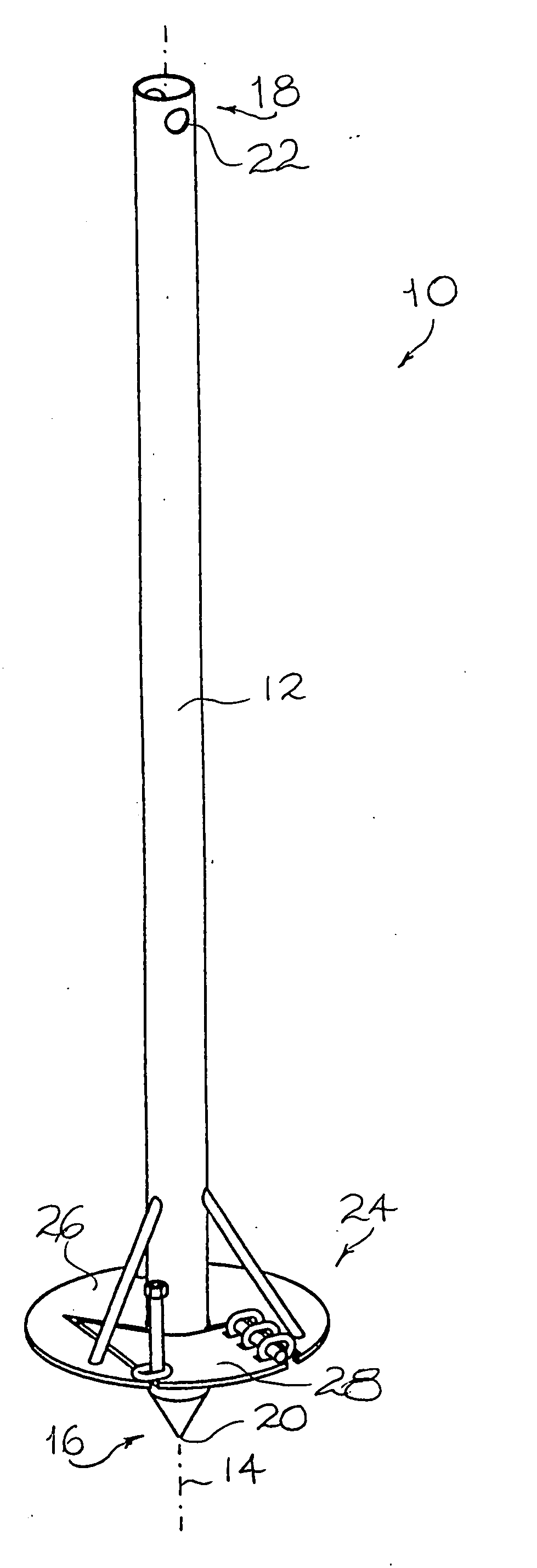

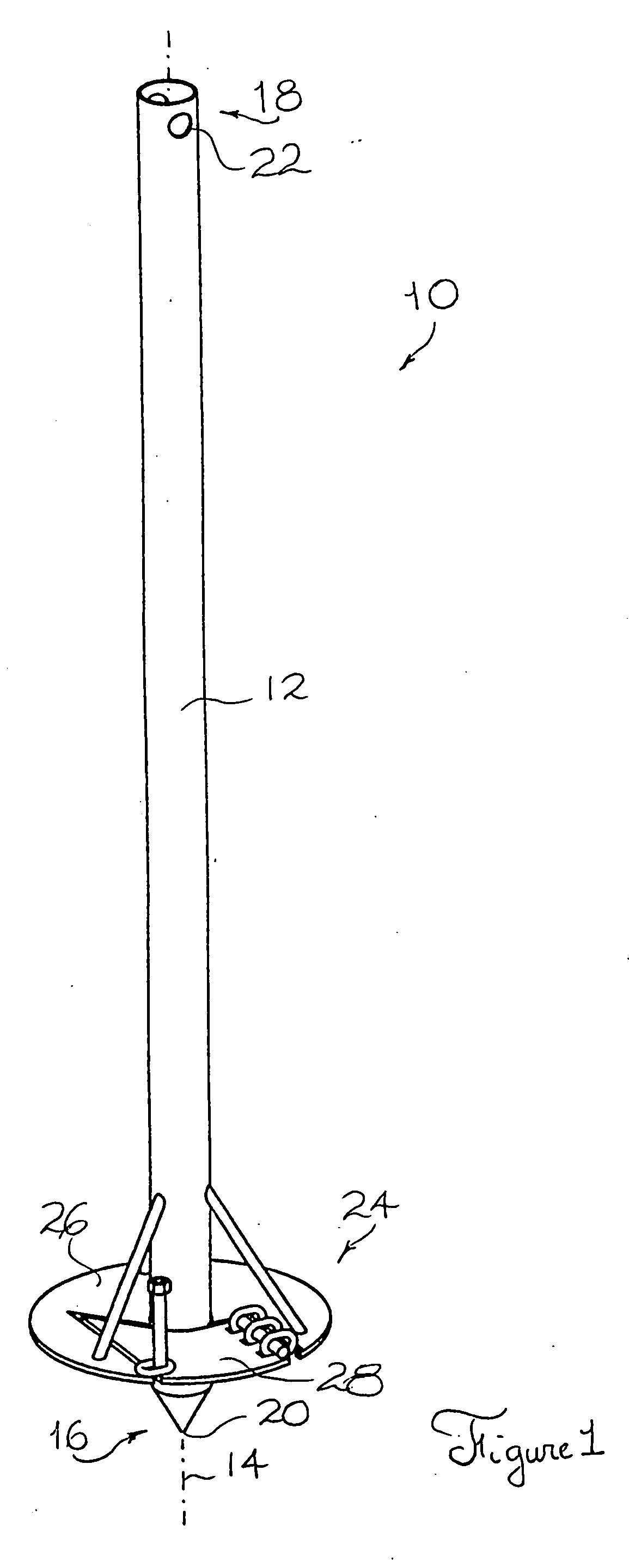

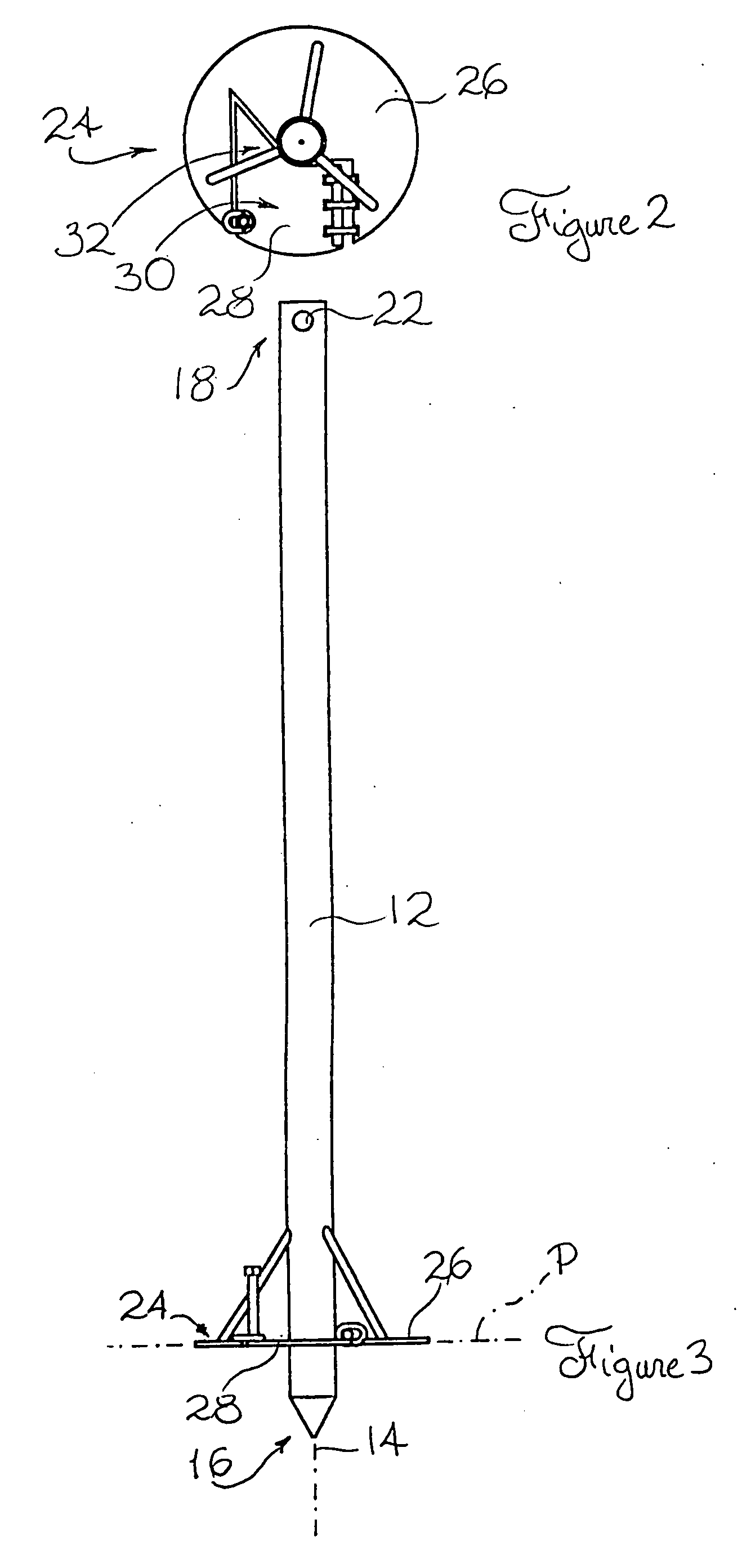

[0039] Referring to FIG. 1, there is shown an anchoring device in accordance with an embodiment of the present invention, generally indicated by the reference numeral 10. The anchoring device 10 is intended to be used mainly for anchoring an object (not shown) into a ground material (also not shown). The object may take any suitable form such as that of a car shelter, a tent, a balcony or any other suitable object without departing from the scope of the present invention. Also, the ground material may take any suitable form such as that of earth, sand, clay or any other suitable ground material without departing from the scope of the present invention.

[0040] Typically, the anchoring device is adapted to be anchored into the ground material using a driving tool (not shown) for providing a rotational driving force. Alternatively, the anchoring device 10 could be anchored into the ground manually. It should be understood that various types of driving tools could be used together with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap