Kinetic sculpture and method of assembling same

a kinetic sculpture and sculpture technology, applied in toys, entertainment, domestic applications, etc., can solve the problems of limiting the configuration of the overall shape of the sculpture, contributing significantly to the cost of manufacturing the sculpture, etc., and achieve the effect of reducing skill and time and broadening the possible configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

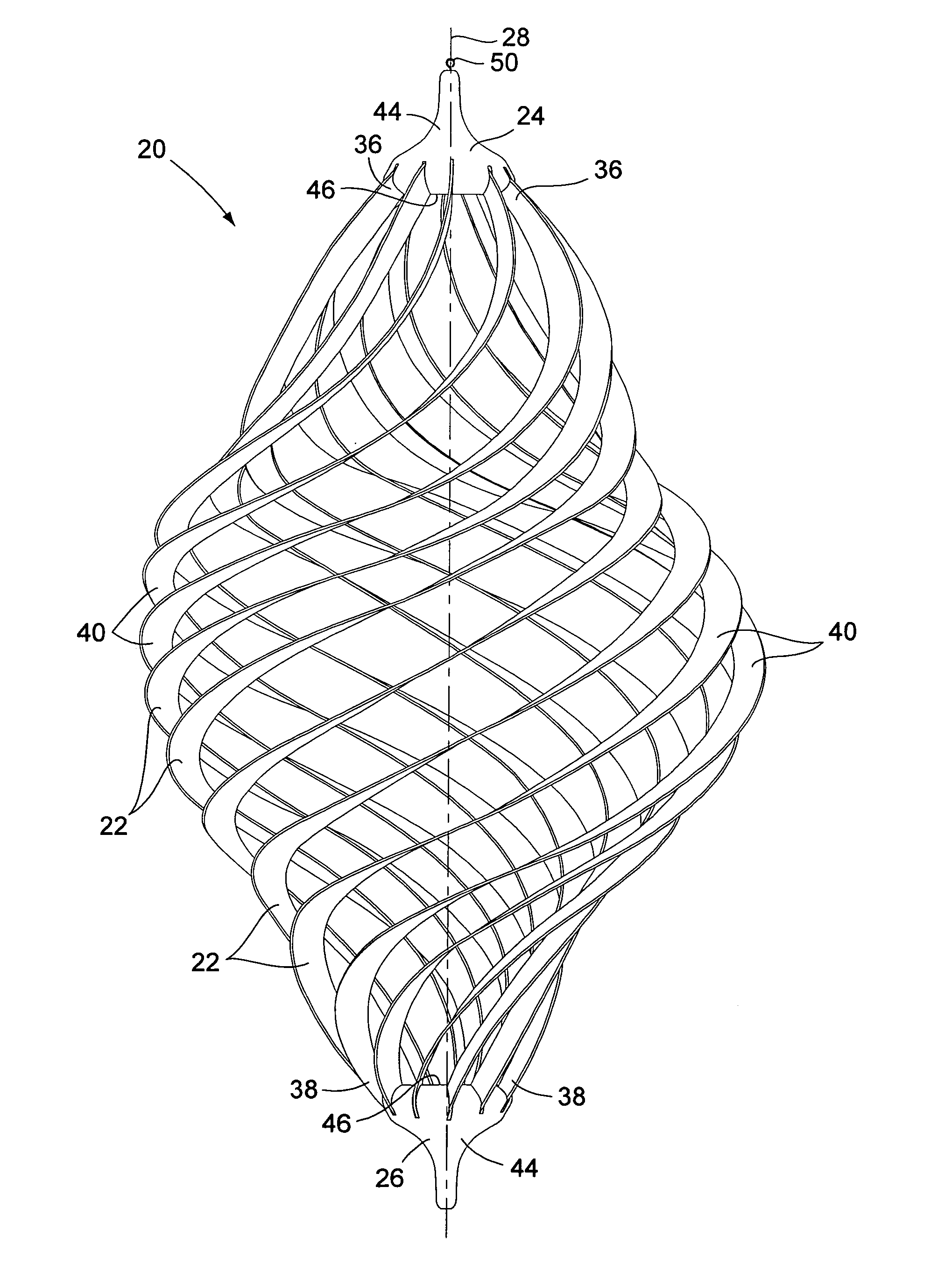

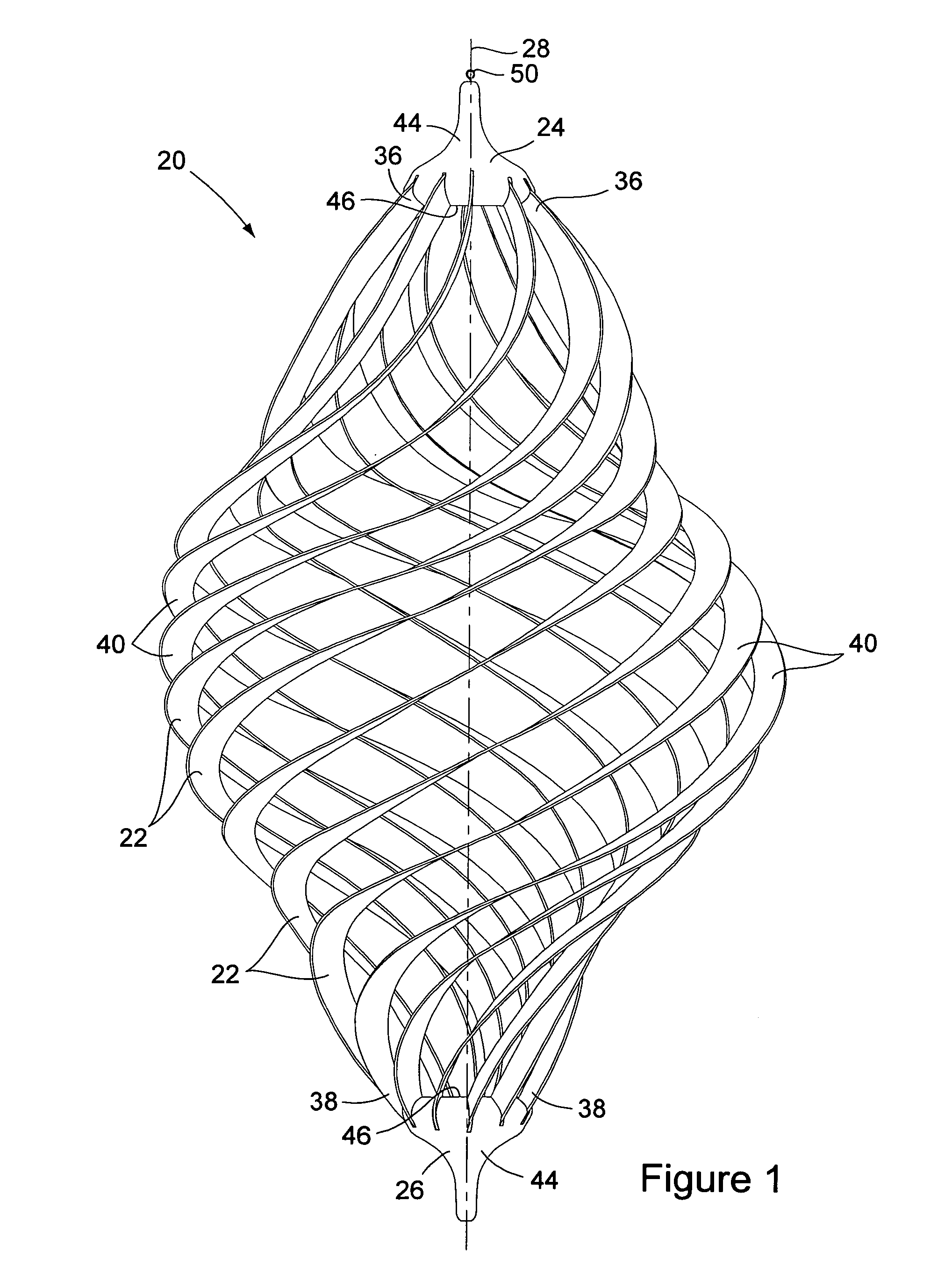

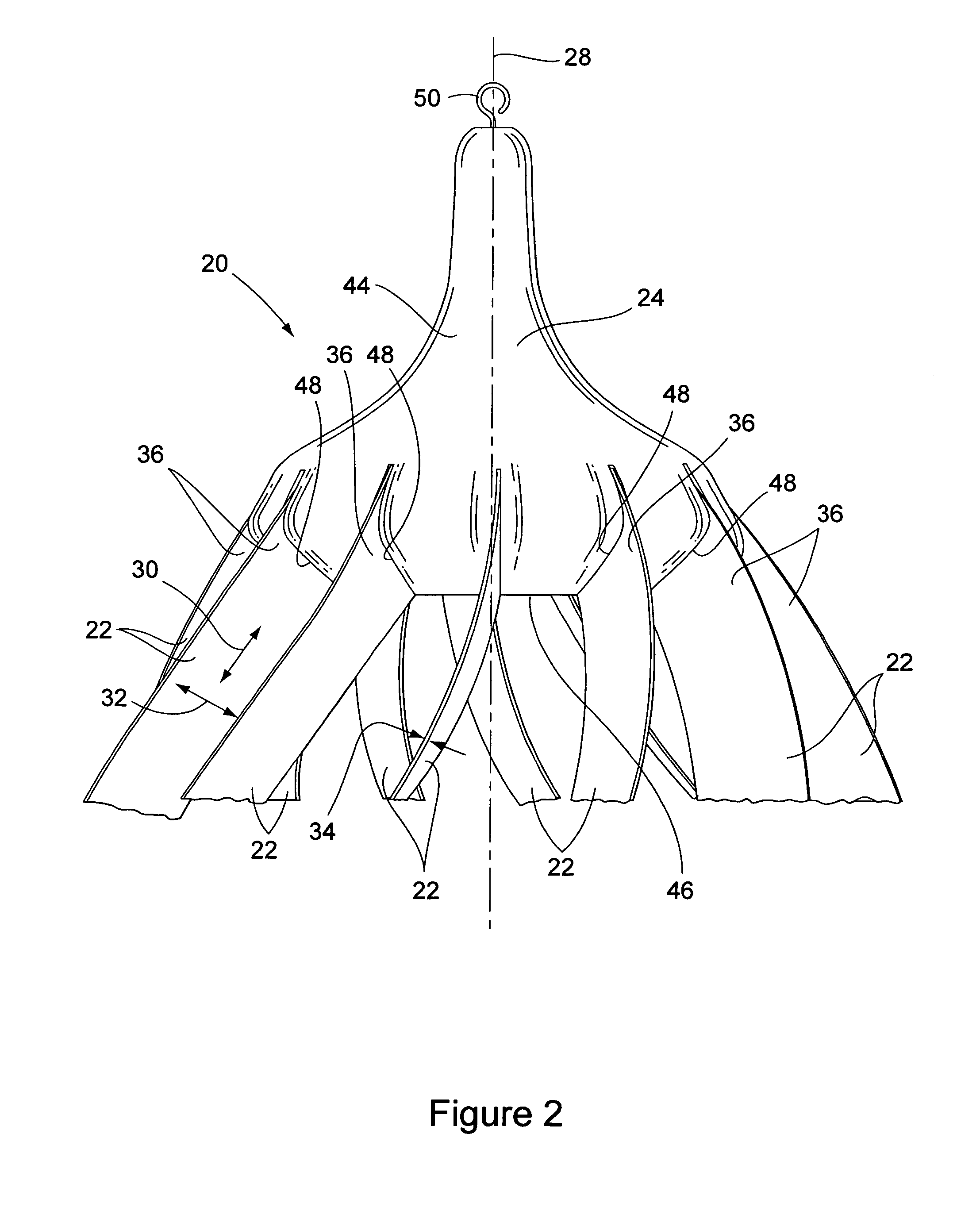

[0017] A first embodiment of a kinetic sculpture 20 of the present invention is shown in its entirety in FIG. 1. The kinetic sculpture 20 preferably comprises a plurality of vanes 22 and top 24 and bottom 26 assembly members. The vanes 22 are preferably formed out of metal, such as copper, and may be coated with decorative finishes or allowed to patina. The assembly members may be formed out plastic, metal, wood, or any other suitable materials.

[0018] The vanes 22 of the kinetic sculpture 20 are preferably identical in shape and spiral about the axis of rotation 28 of the kinetic sculpture. Each vane 22 is preferably die cut in a spiral pattern from a flat piece of sheet material and is thereafter stretched out of plane such that the vane longitudinally extends along the axis of rotation 28 as it spirals thereabout. Each vane 22 has a longitudinal length 30, a width 32, and a thickness 34 that are mutual transverse to each other at each point along the vane. Additionally, each vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com