Plate concrete dowel system

a concrete and plate technology, applied in the direction of paving details, constructions, roads, etc., can solve the problems of horizontal movement relative to pour joints, and achieve the effect of facilitating the movement facilitating the centering of the dowel pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

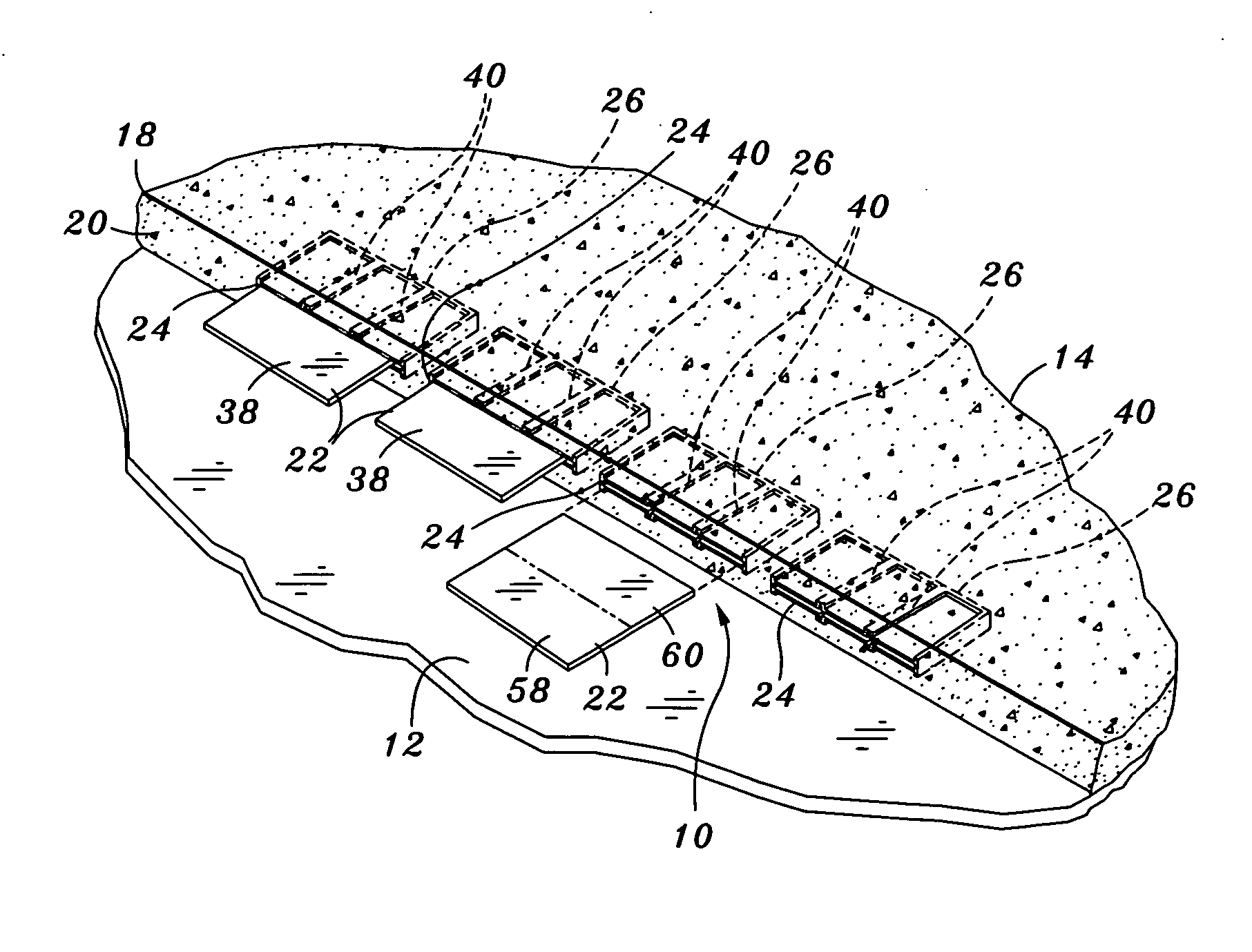

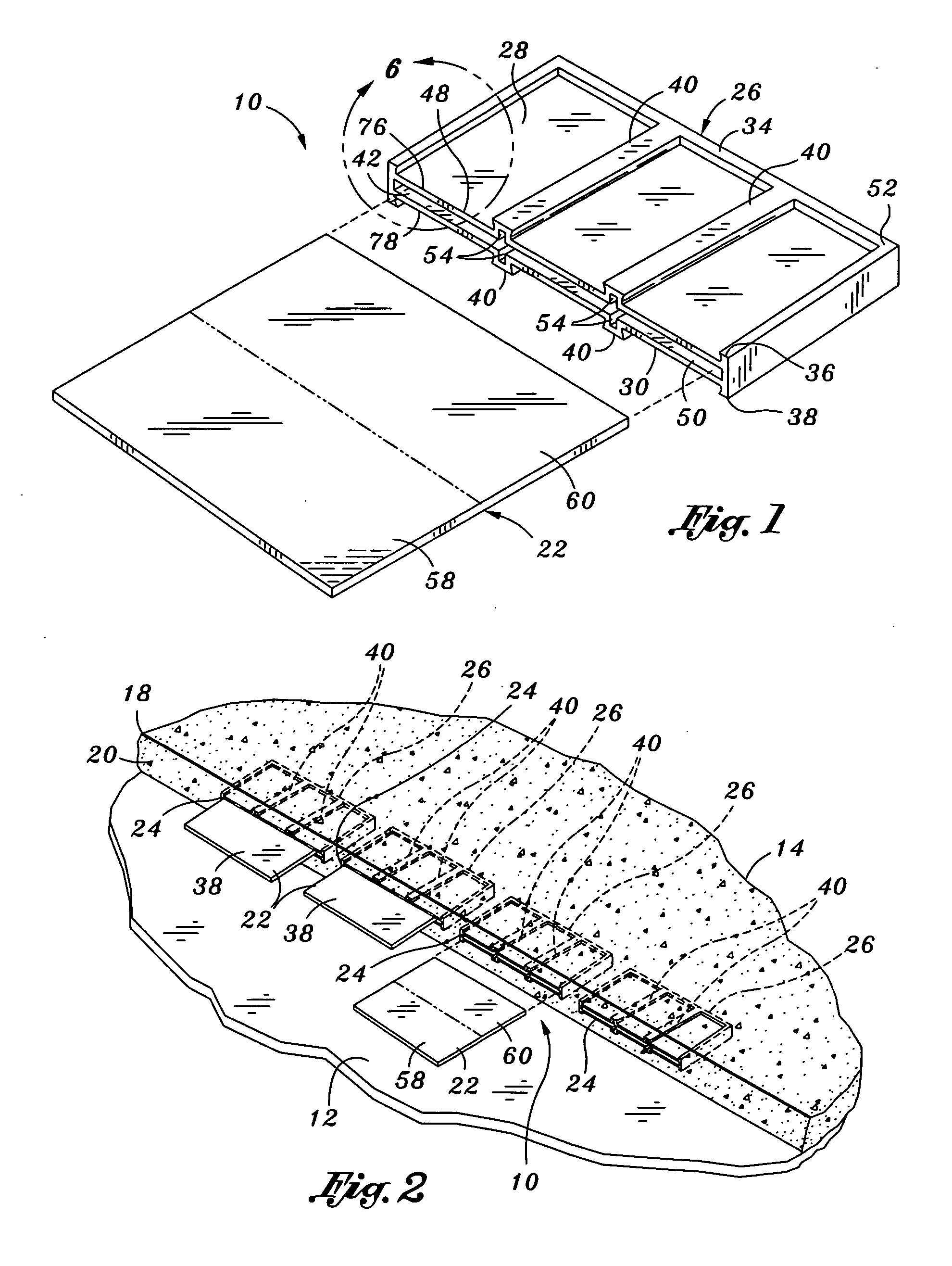

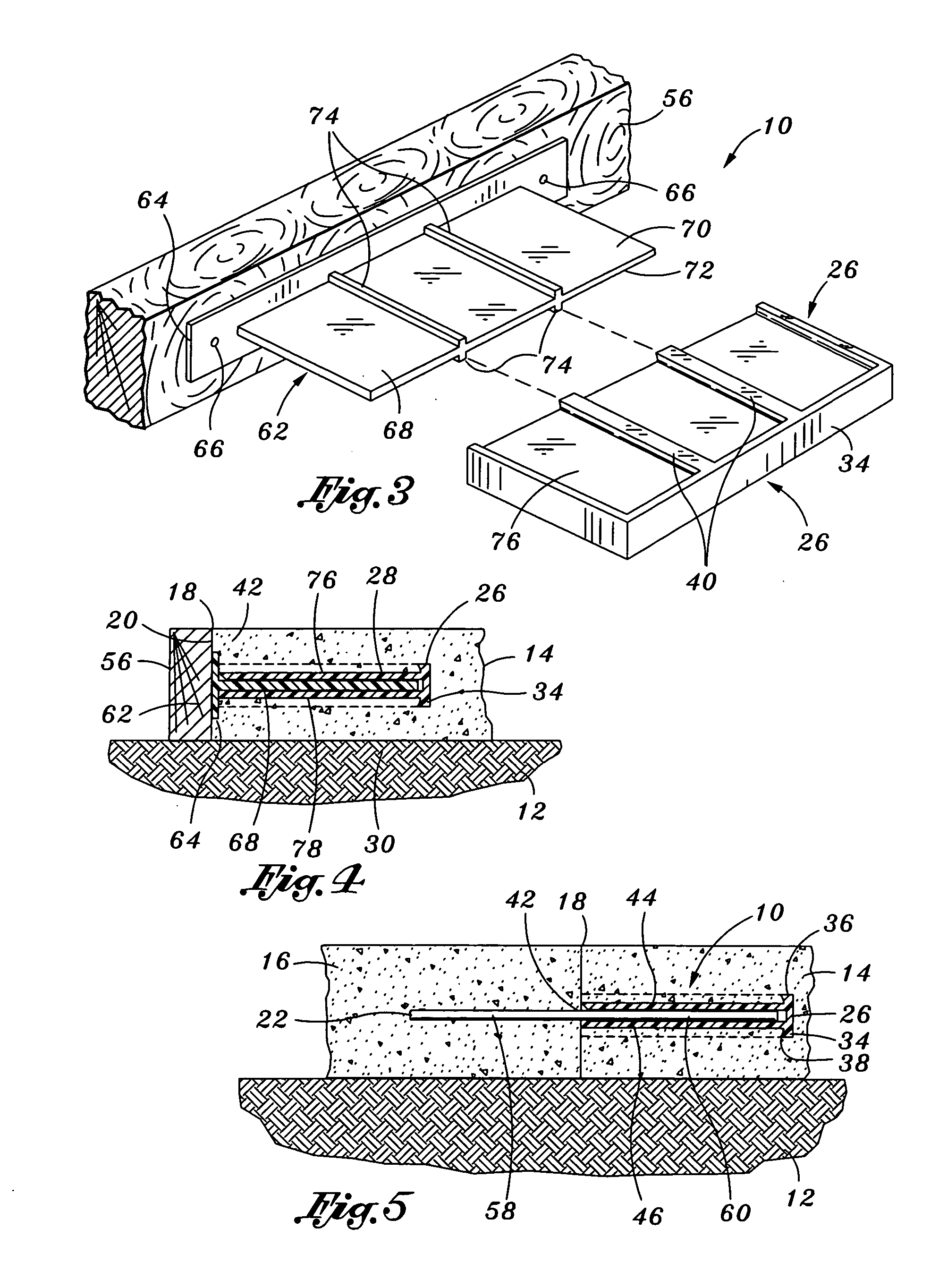

[0038] Referring now to the drawings wherein the showings are for purposes of illustrating the present invention and not for purposes of limiting the same, FIG. 1 illustrates a dowel plate 22 and corresponding pocket former 26 of the disc dowel system 10 of the present invention. The disc dowel system 10 is installed at a pour joint 18 between a first concrete pour 14 and a second concrete pour 16 disposed above a subgrade or a substrate 12, as can be seen in FIG. 5. The substrate 12 may be soil underlying the first and second pours 14, 16. Alternatively, the substrate 12 may be a metal decking or other surface that is adapted to support concrete.

[0039] As can be seen in FIGS. 1 and 2, the disc dowel system 10 is comprised of the dowel plate 22 and the pocket former 26. In FIG. 2, a series of the pocket formers 26 are shown encapsulated in the first pour 14 prior to pouring of the second pour 16. The disc dowel system 10 may further include a positioner bracket 62 for positioning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com