Garbage can

a garbage can and lid technology, applied in the field of garbage cans, can solve the problems of inconvenient use, difficult assembly, uneasy assembly, etc., and achieve the effect of convenient opening or closing and more steady standing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

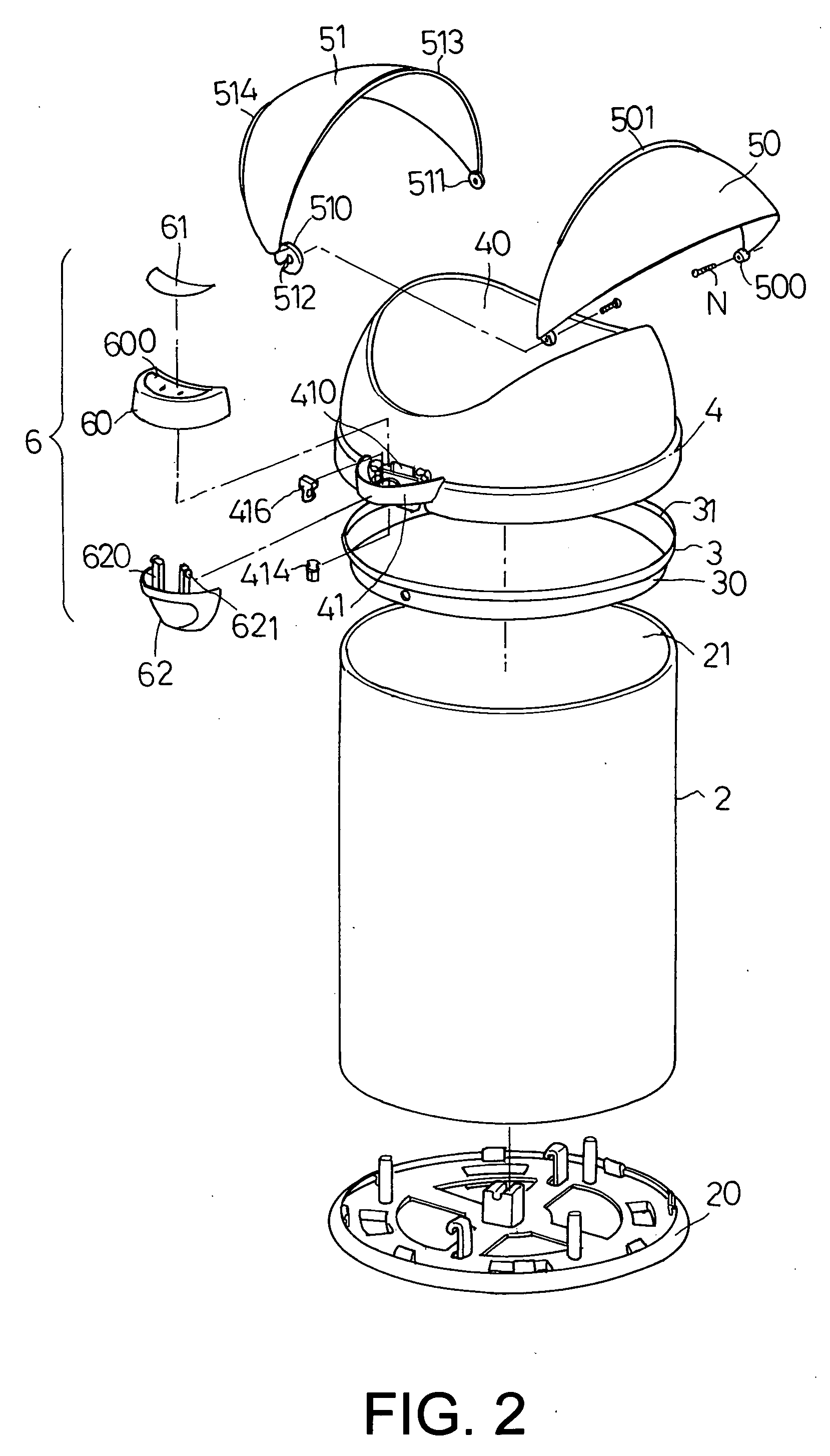

[0018] A preferred embodiment of a garbage can in the present invention, as shown in FIGS. 2-7, includes a can body 2, a ring 3, a stationary cover 4, two movable curved covers 50, 51 and a pressing device 6.

[0019] The can body 2 has a bottom base 20 at its bottom and an opening 21 on top.

[0020] The ring 3 sitting around the opening 21 of the can body 2 possesses an annular edge 30 at its bottom and a fitting annular edge 31 on top.

[0021] The stationary cover 4 matching with the fitting annular edge 31, has an opening 40 in the center, a projection 41 with a hole 410 at its side, a fitting groove 411 and a slide base 412 on a side to be connected with the stationary cover 4, a post hole 413, a fitting piece 414 and a spring 415 at the center, a locking member 416 near its outer edge and two holes 417 in front of the locking member 416, and two fixing rods 42 in the inside.

[0022] The two movable curved covers 50, 51 are to be bolted with the fixing rods 42 of the stationary cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com