Ink supply amount adjustment method and apparatus for printing press

a technology of printing press and amount adjustment, which is applied in the direction of printing press parts, printing, printing presses, etc., can solve the problems of increasing taking a very long time, and the need to restart proof printing, so as to reduce the amount of wasted paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

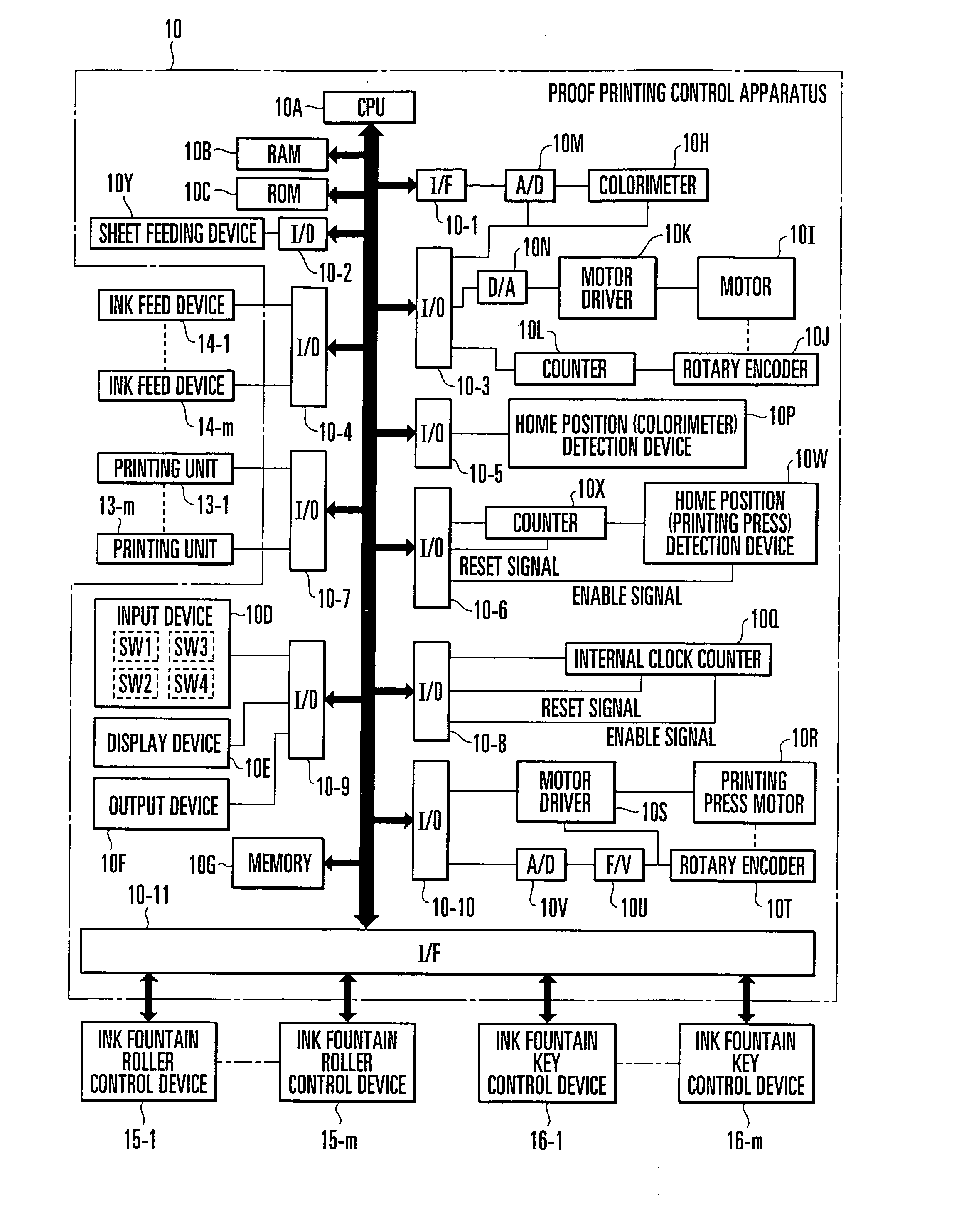

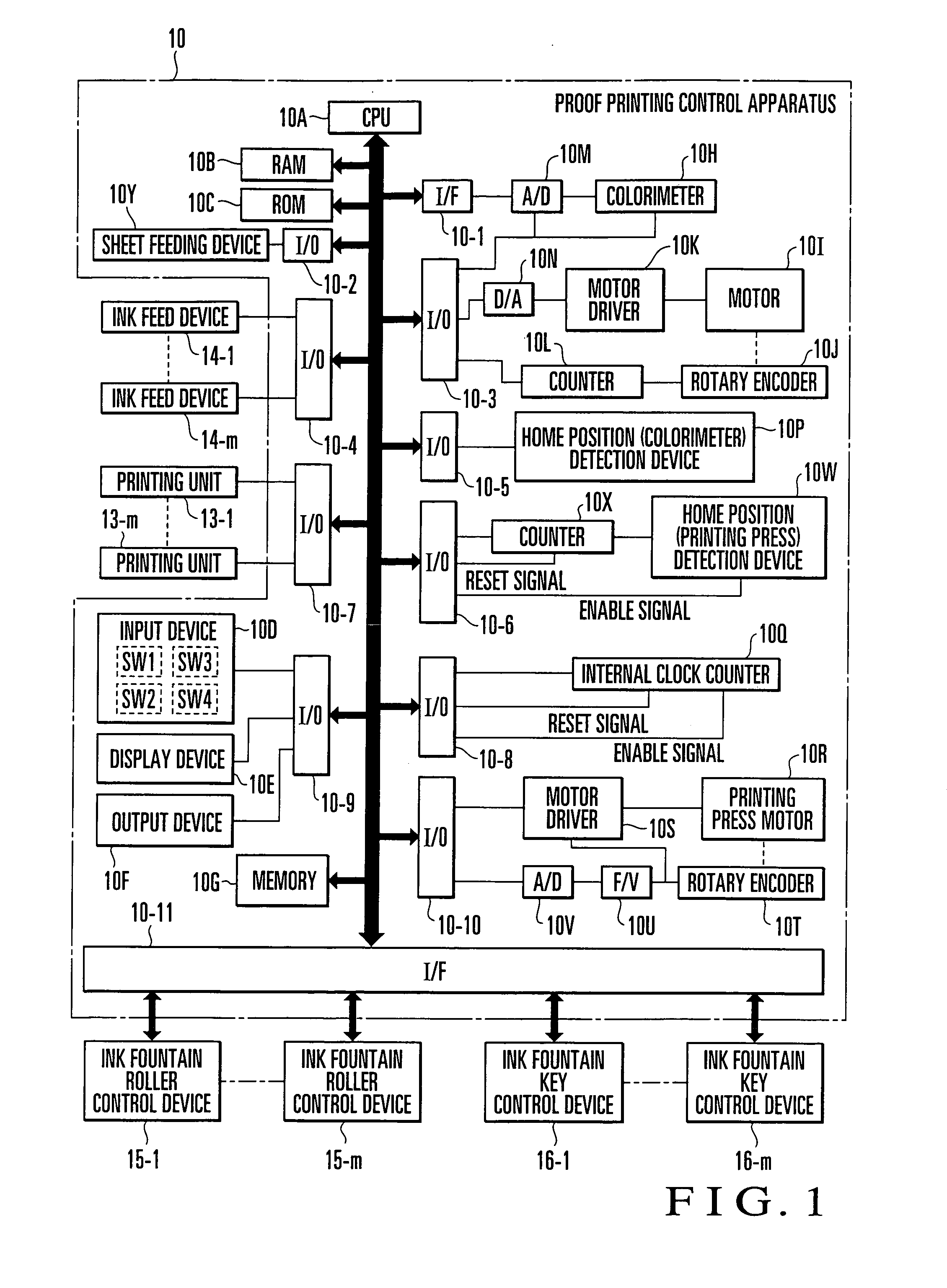

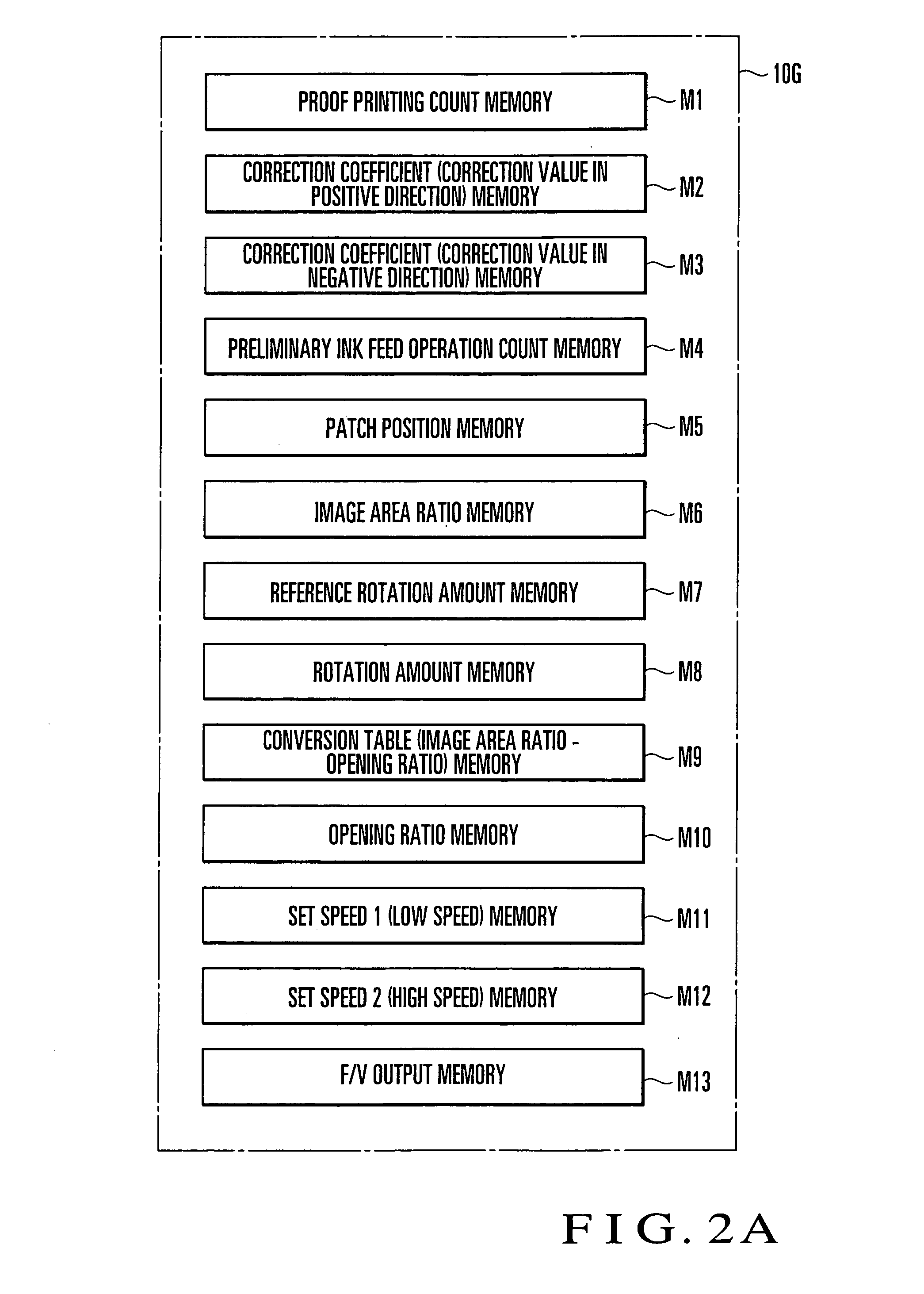

[0030]FIG. 1 shows a proof printing control device according to this embodiment of the present invention. A proof printing control device 10 comprises a CPU 10A, a RAM 10B, a ROM 10C, an input device 10D, a display device 10E, an output device 10F, a memory 10G, a colorimeter 10H, a colorimeter moving motor 10I, a rotary encoder 10J for the calorimeter moving motor, a motor driver 10K for moving the colorimeter, a counter 10L for measuring the current position of the colorimeter, an A / D converter 10M, a D / A converter 10N, a detector 10P for detecting the home position of the colorimeter, an internal clock counter 10Q, a driving motor 10R of a printing press, a driver 10S of a printing press driving motor, a rotary encoder 10T for the printing press driving motor, an F / V converter 10U, an A / D converter 10V, a detector 10W for detecting the home position of the printing press, counter 10X for counting total rotational speed of the printing press, a sheet feeding device 10Y, and input / ...

second embodiment

[0106] In the first embodiment, the reference correction amount of the ink fountain key opening ratio is multiplied by a predetermined correction coefficient (>1) to obtain the correction amount. This correction amount is added to the current ink fountain key opening ratio to obtain the ink fountain key opening ratio in the preliminary ink feed operation. In contrast to this, in the second embodiment, the reference correction amount of the ink fountain key opening ratio is added to the current ink fountain key opening ratio to obtain the ink fountain key opening ratio in the preliminary ink feed operation. In this case, the ink fountain key opening ratio of each color in the preliminary ink feed operation equals the ink fountain key opening ratio of each color in next proof printing. Hence, the ink fountain key opening ratio need not be adjusted after the preliminary ink feed operation.

[Schematic Operation in Second Embodiment]

[0107] (1) Each data is input.

[0108] (2) A proof prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com