Suction brush for a vacuum cleaner

a vacuum cleaner and suction brush technology, applied in the direction of vacuum cleaners, cleaning equipment, domestic applications, etc., can solve the problems of deteriorating manipulation capability, inconvenience for users, and deteriorating manipulation ability of moving the suction brush, so as to improve the manipulation capability of the suction brush, minimize noise generation, and introduce smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinbelow, certain embodiments of the present invention are described in detail with reference to accompanying drawings. In the following description, a detailed description of known functions and configurations incorporated herein will be omitted when it may make the subject matter of the present invention rather unclear.

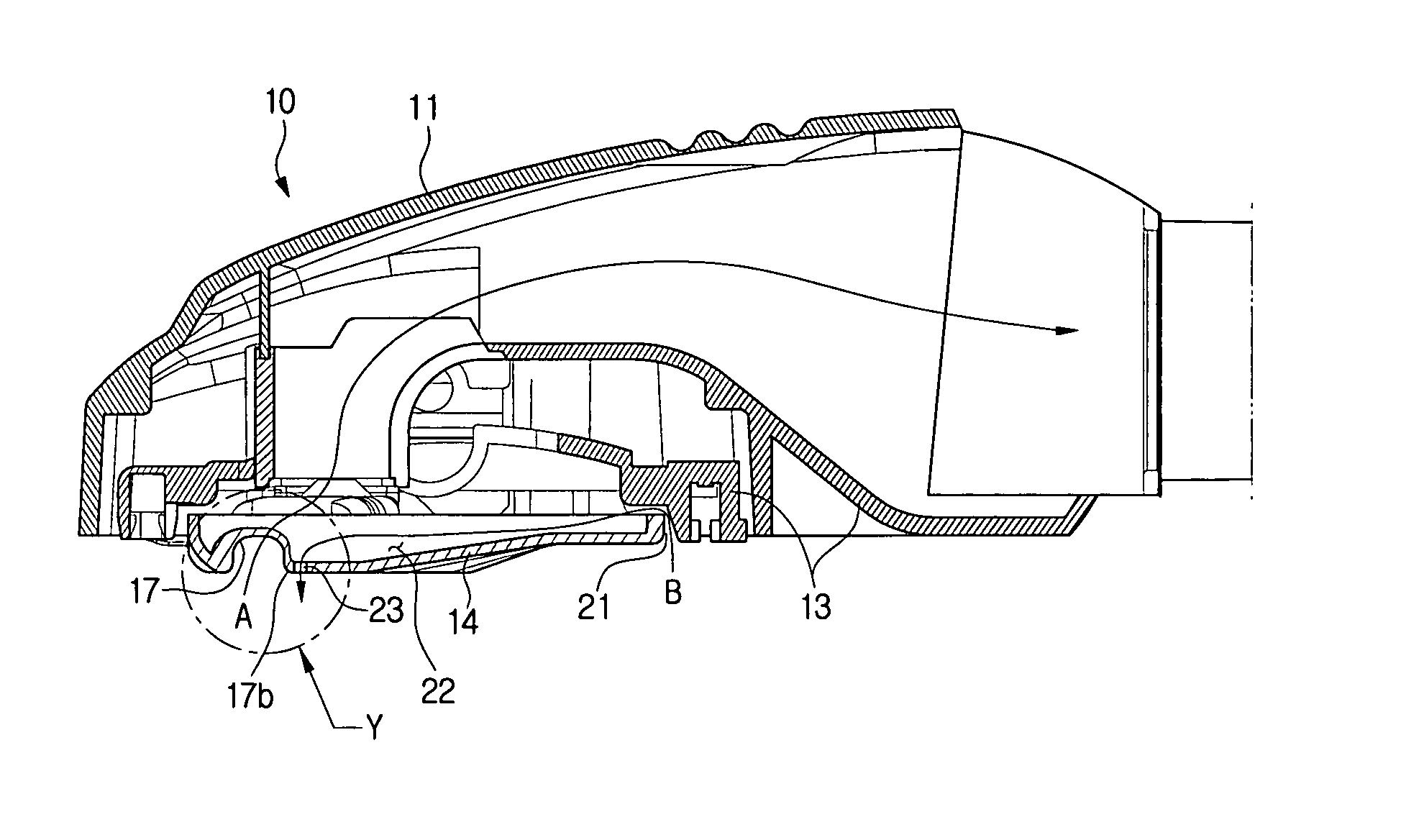

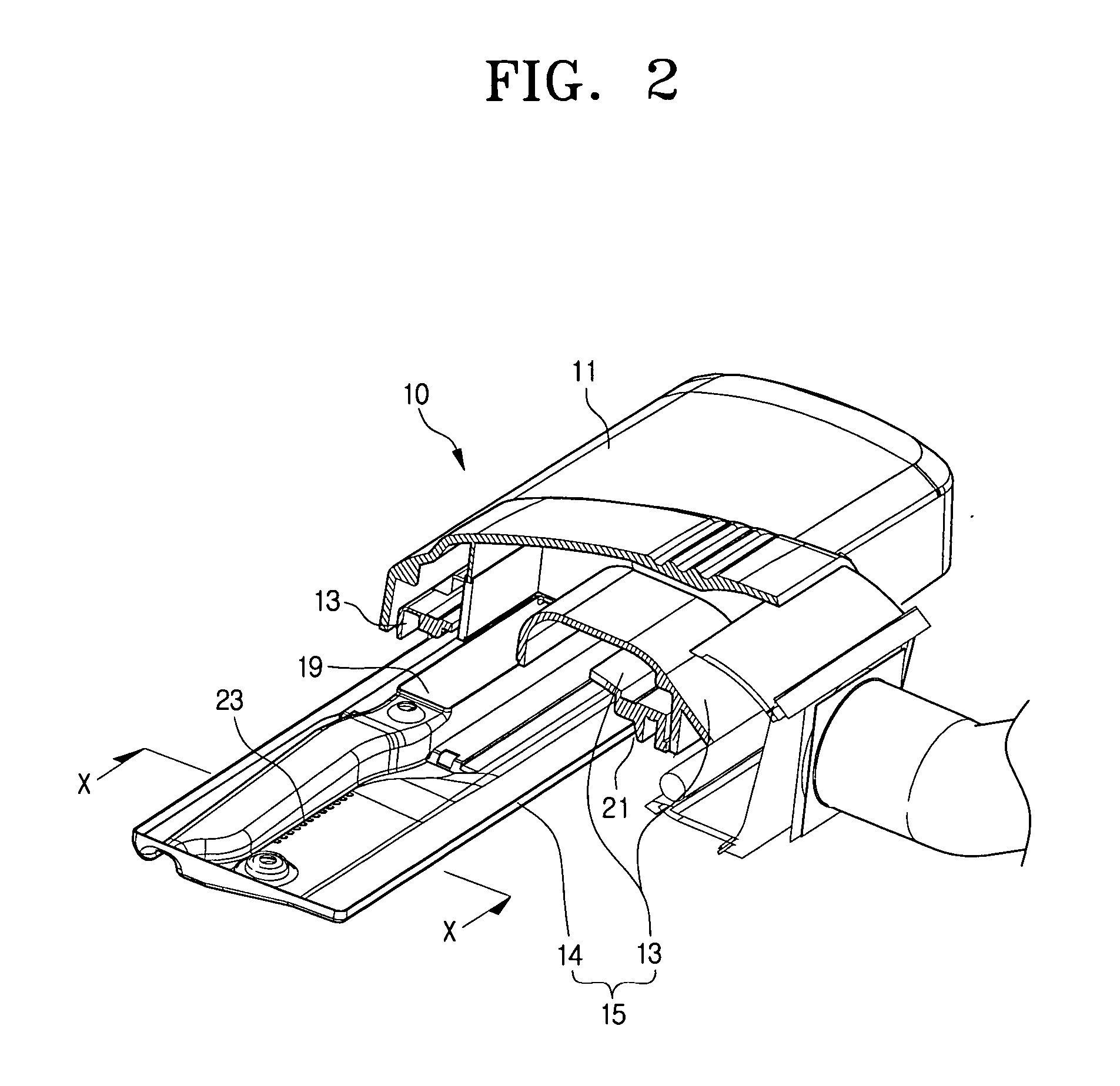

[0025]FIG. 2 is a partially cut-away perspective view illustrating an internal construction of a suction brush of a vacuum cleaner according to an embodiment of the present invention, FIG. 3 is a bottom view of the suction brush of FIG. 2, and FIG. 4A is a cross-sectional view taken along line X-X of FIG. 2, and FIG. 4B is a enlarged view of Y illustrated in FIG. 4A.

[0026] As shown in FIG. 2, the suction brush 10 of a vacuum cleaner according to an embodiment of the present invention has a body 15 which comprises a bottom panel 14 which contacts the surface to be cleaned, a top panel 13 located on the top of the bottom panel 14.

[0027] As shown in FIG. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com