Shelf tray assembly

a shelf tray and assembly technology, applied in the field of improved shelves, can solve the problems of difficult removal of track and movement, and achieve the effect of better holding and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

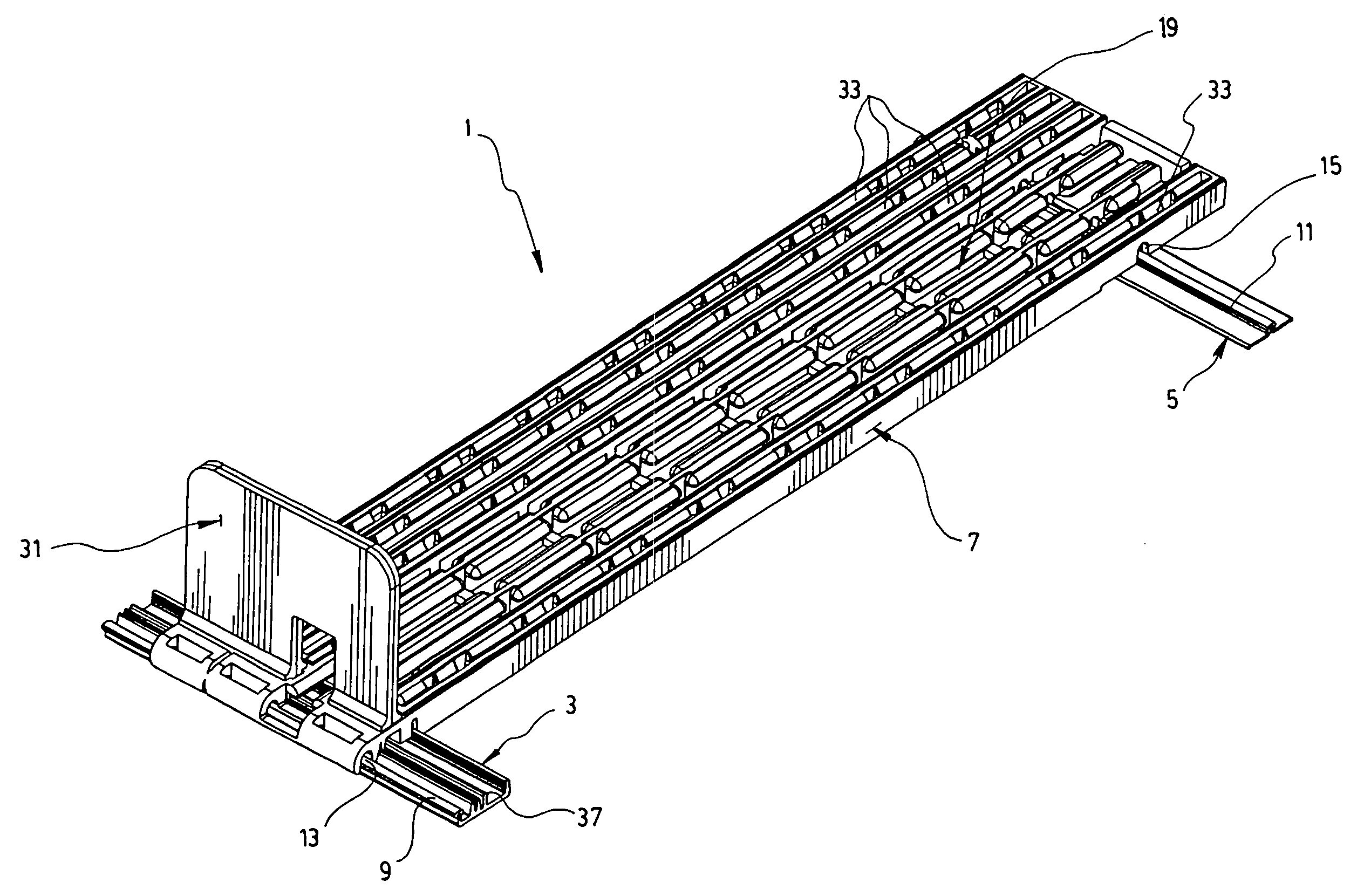

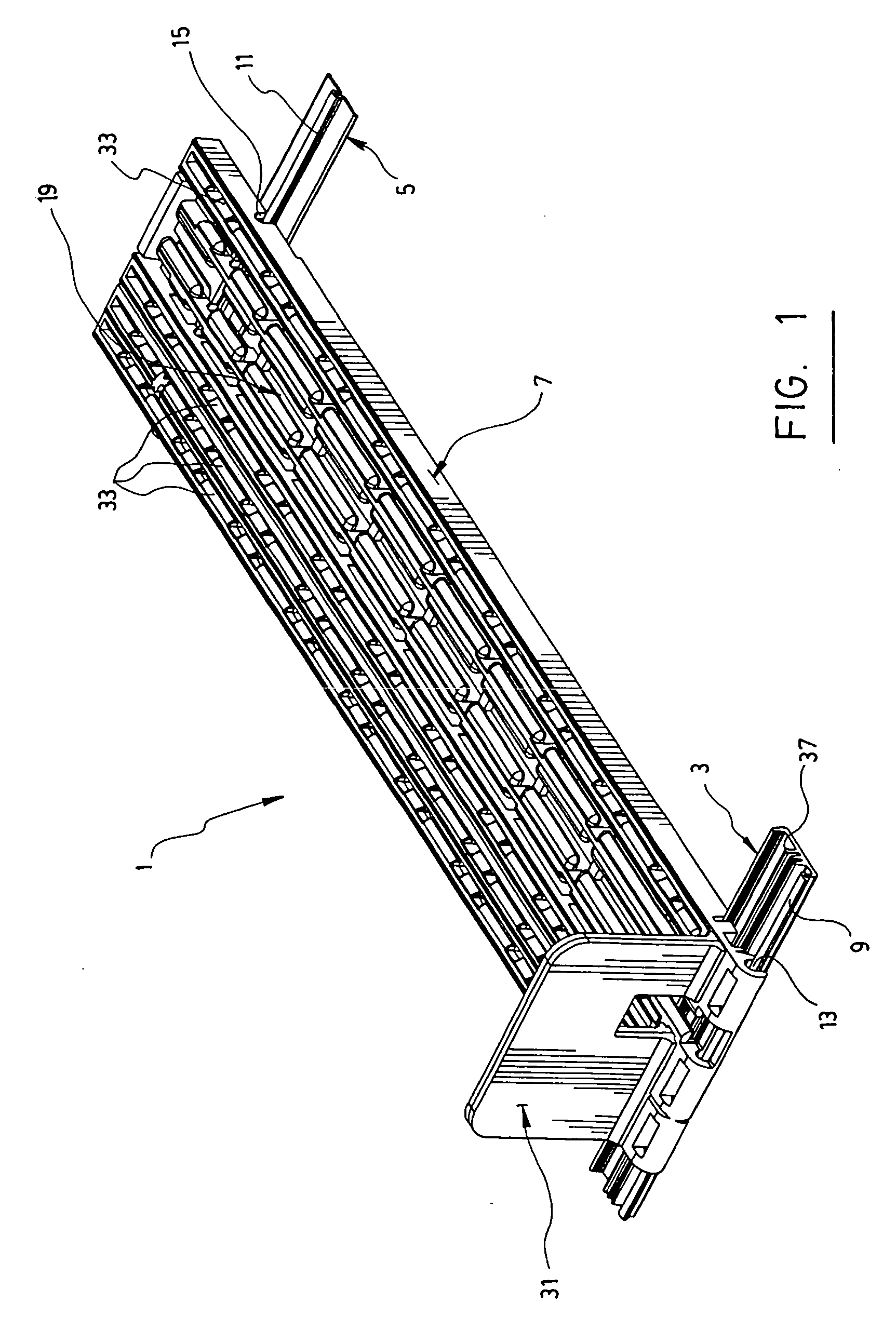

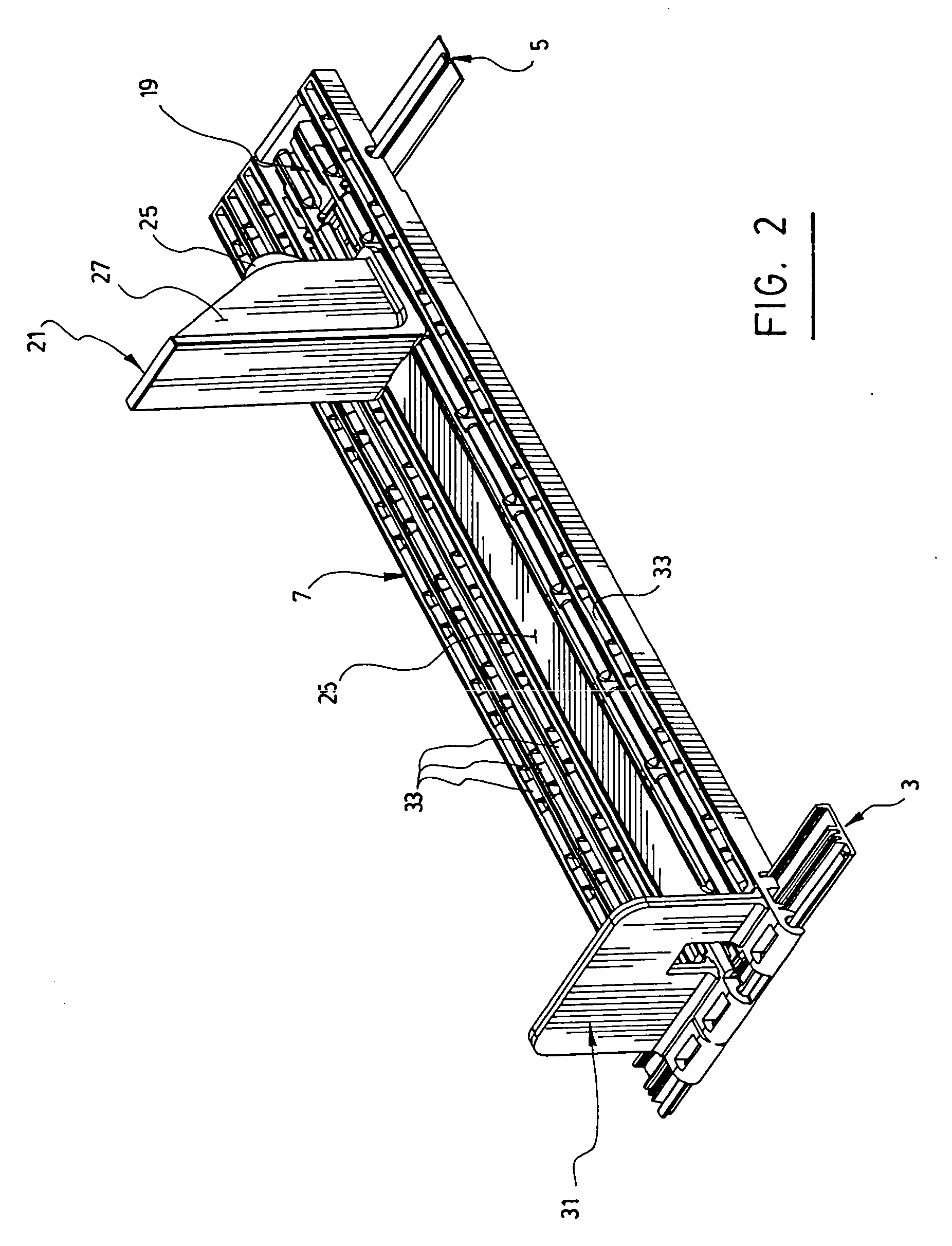

[0037] The improved shelf tray assembly 1 according to the preferred embodiment of the invention as shown in the accompanying drawings is intended to be used for holding and moving forward in a simple and efficient way a plurality of articles of a given dimension placed on a shelf toward a front edge of the shelf in order to allow frontal display of these articles. This assembly basically comprises: [0038] (i) a front rail 3 installable onto the shelf close to its front edge [0039] (ii) a rear rail 5 that is parallel to the front rail and installable onto the shelf at a distance away from the front rail; and [0040] (iii) at least one track 7 extending perpendicularly to the front edge of the shelf.

[0041] As is better shown in FIGS. 14a and 14b, the front rail 3 has an upper surface of a given length with an upwardly projecting tongue 9 extending all over its length. As is shown in FIGS. 15a and 15b, the rear rail 5 also has an upper surface of a given length with an upwardly projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com