Heat pipes utilizing load bearing wicks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

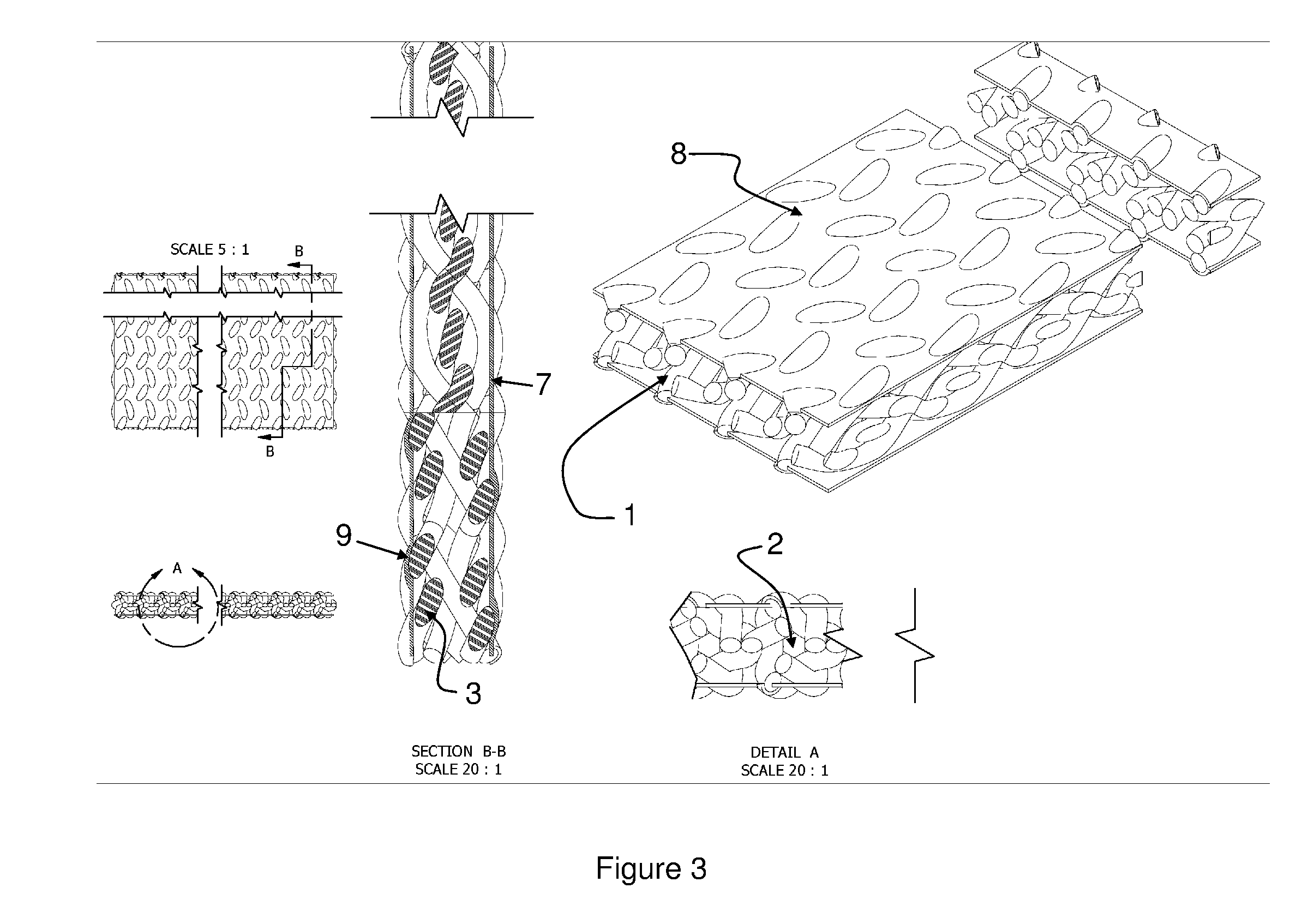

[0006] This invention overcomes cited technical challenges utilizing a soft shell and a load bearing wick structure in a heat pipe design. Unlike competitive technologies it provides convenient topological solution for compact designs, confined spaces, and flexible solutions.

Wick

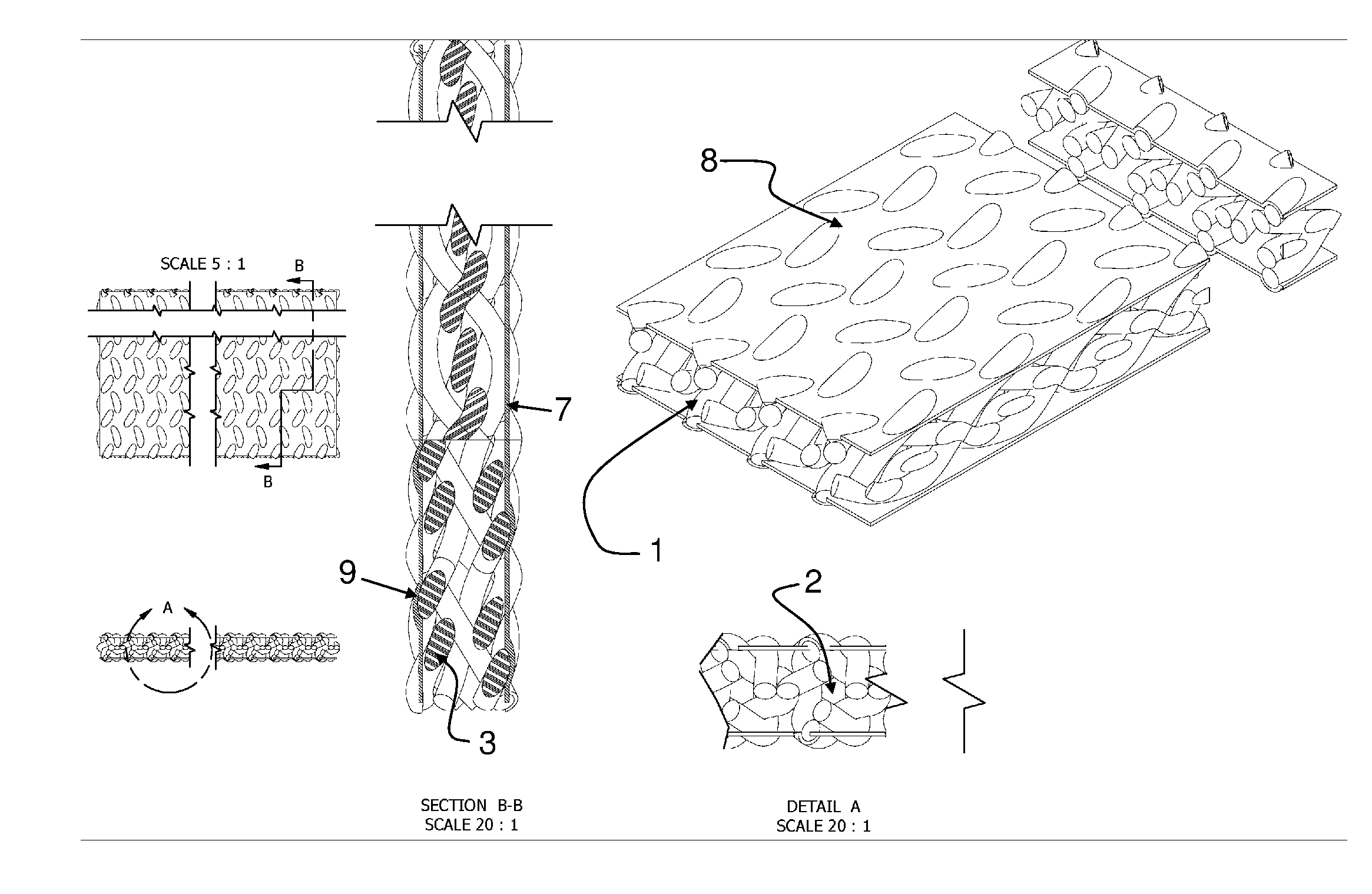

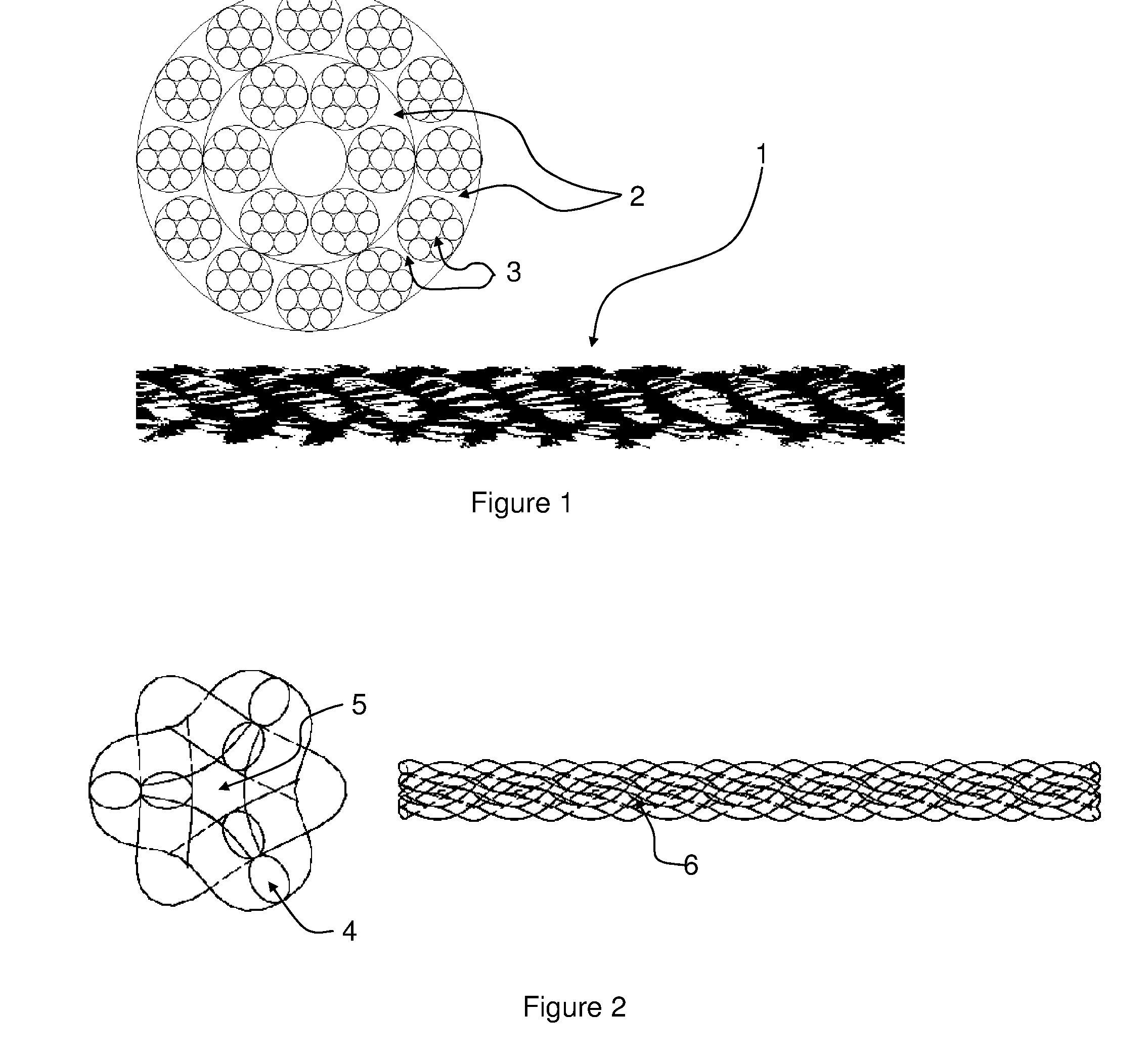

[0007]FIG. 1 shows schematic the structure of the wick. Preferred embodiment of the invention uses a wick 1 is formed by braided fiber. The yarns are braided to form plaits along preferred direction of the pipe. Each yarn could be formed by braided fiber or tows. 6-tow maypole braided construction is a good example for one of many possible yarn designs.

[0008] The total wick structure accounts for small (capillary 3) and large (passages 2) gaps. The capillary are formed by fiber-fiber gaps and inner-yarn tubes, Inner yarn tube is formed when small number of carriers (4-8) are used in rotary or maypole braiding. The passages are formed by yarn-yarn and braid-braid spacing. This construction has high mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com