Collapsible window blinds structure

a window blind and collapsible technology, applied in the direction of shutters/movable grilles, door/window protective devices, wing arrangements, etc., can solve the problems of difficult increased packaging and carriage costs, and conventional window blind structure, so as to facilitate carriage and storage of window blinds, save production costs, and boost competitive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

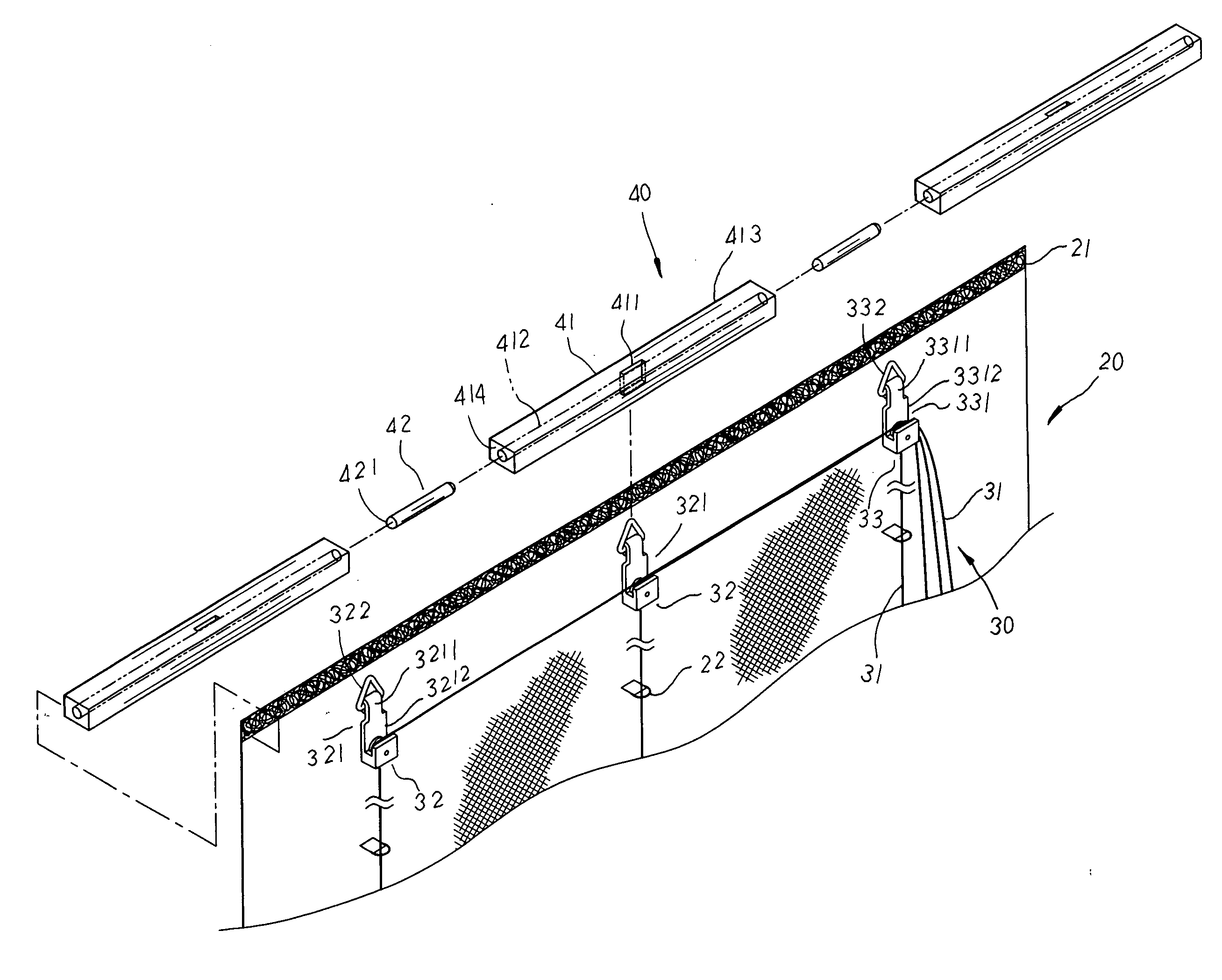

[0016] Please refer to FIG. 3 showing an exploded perspective view of the present invention. The present invention is related to a collapsible window blinds structure, comprising a blind body 20, a lift cord set 30, and a head rail assembly 40 wherein the blind body 20 has a fastening portion 21 made up of hook-side fasteners disposed at the top edge thereon, and a plurality of limiting hoops 22 evenly spaced and fixed in vertical lines at the rear side surface thereon. The lift cord set 30 is composed of lift cords 31, pulley seats 32 and a positioning pulley unit 33 wherein the lift cords 31 are guided through the limiting hoops 22 of the blind body 20 to wind around the pulley seats 32 and the positioning pulley unit 33 and fixed to the bottommost limiting hoops 22 thereof respectively. In this way, the blind body 20 is raised or lowered according to the collecting or expanding operation of the lift cords 31 thereby. The top edges of the pulley seats 32 and the positioning pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com