Microchannel, flat tube heat exchanger with bent tube configuration

a technology of heat exchanger and microchannel tube, which is applied in the direction of stationary conduit assembly, metal-working apparatus, lighting and heating apparatus, etc., can solve the problems of flat microchannel tube across equivalent bends, wide acceptance as a replacement for the type of heat exchanger, and perceived difficulty or inability to bend relatively wid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

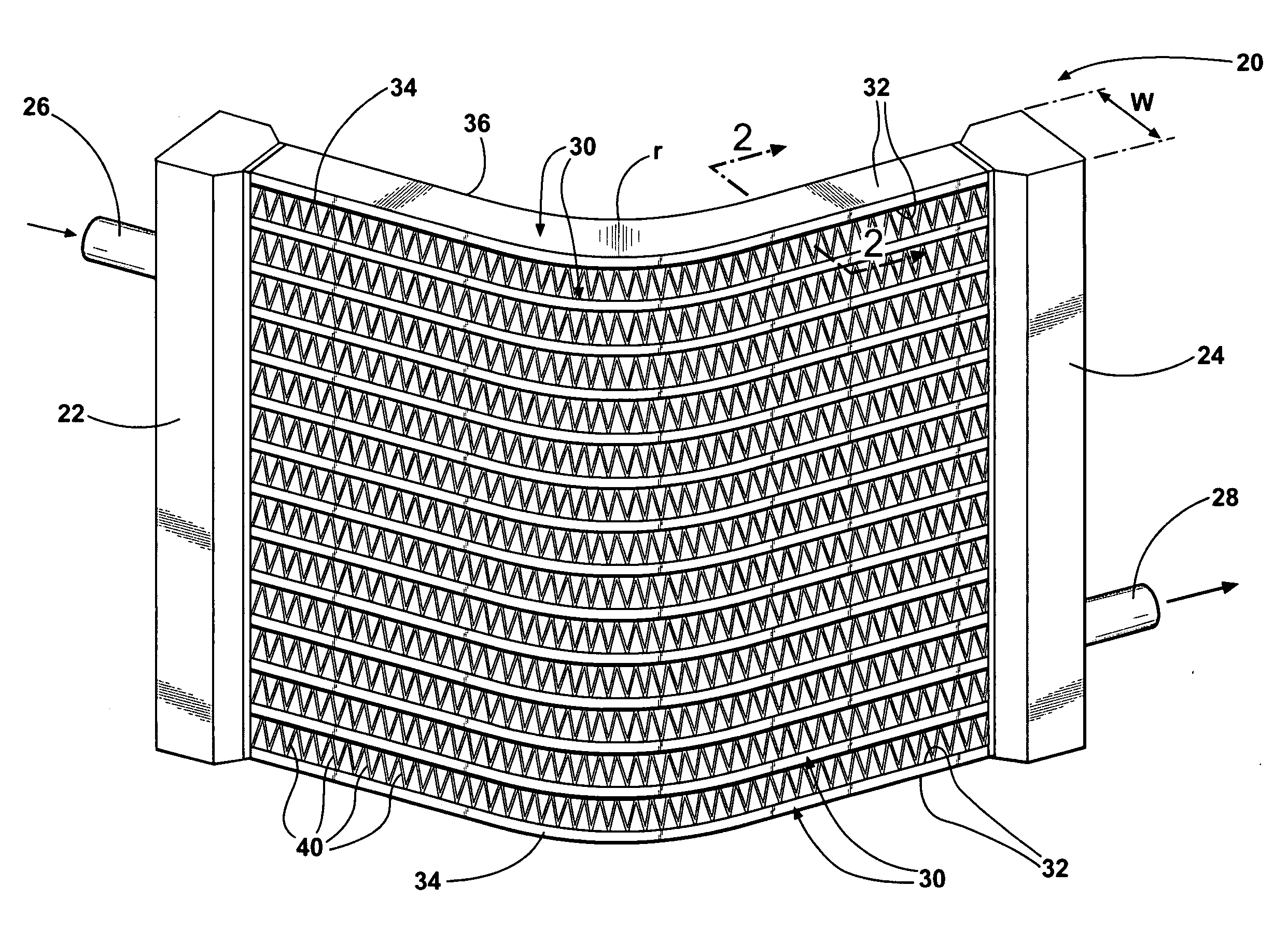

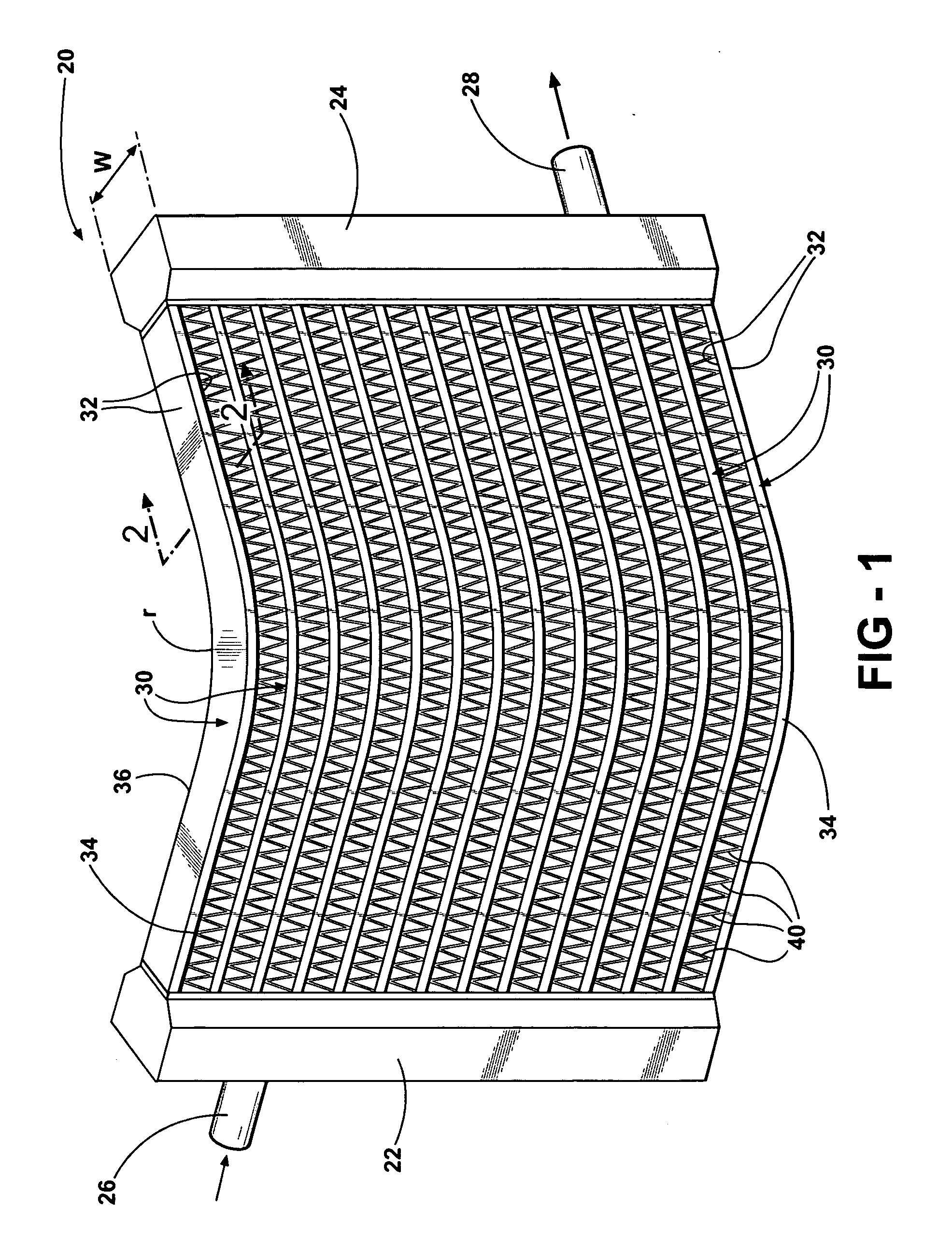

[0016] Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a heat exchanger assembly 20 is generally shown for use in residential air conditioning units in FIGS. 1-3.

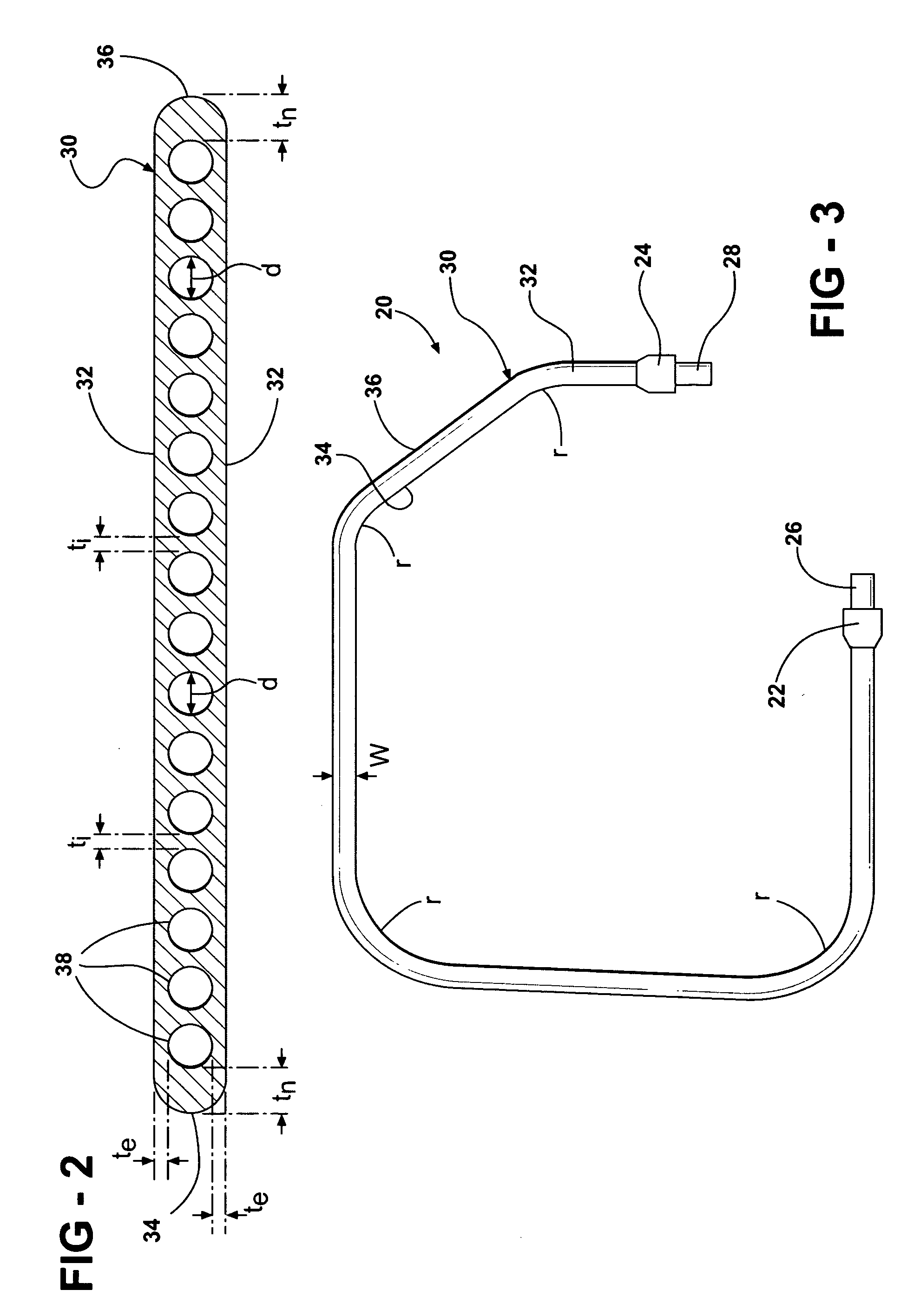

[0017] The assembly 20 comprises a first header 22 and a second header 24 spaced parallel from each other. The first header 22 includes an inlet 26 and the second header 24 includes an outlet 28 for the flow of a liquid through the assembly 20. Although the headers 22, 24 are illustrated as trapezoidal in cross-section, many different configurations may be used, including round and rectangular. A plurality of tube members 30 generally indicated extend between the first header 22 and the second header 24. The tube members 30 have two parallel flat sides 32 that extend between semi-circular first and second noses 34, 36. The first nose 34 and the second nose 36 are spaced a width w from each other. The width w of the tube members 30 is in the range of 12.00 mm to 27....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com