Chair seat structure

a chair seat and seat technology, applied in the field of chair seat structure, can solve the problems of wasting a lot of time and labor in assembling the chair seat, and the seat cannot be quickly dismantled for replacement and repair of its parts,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

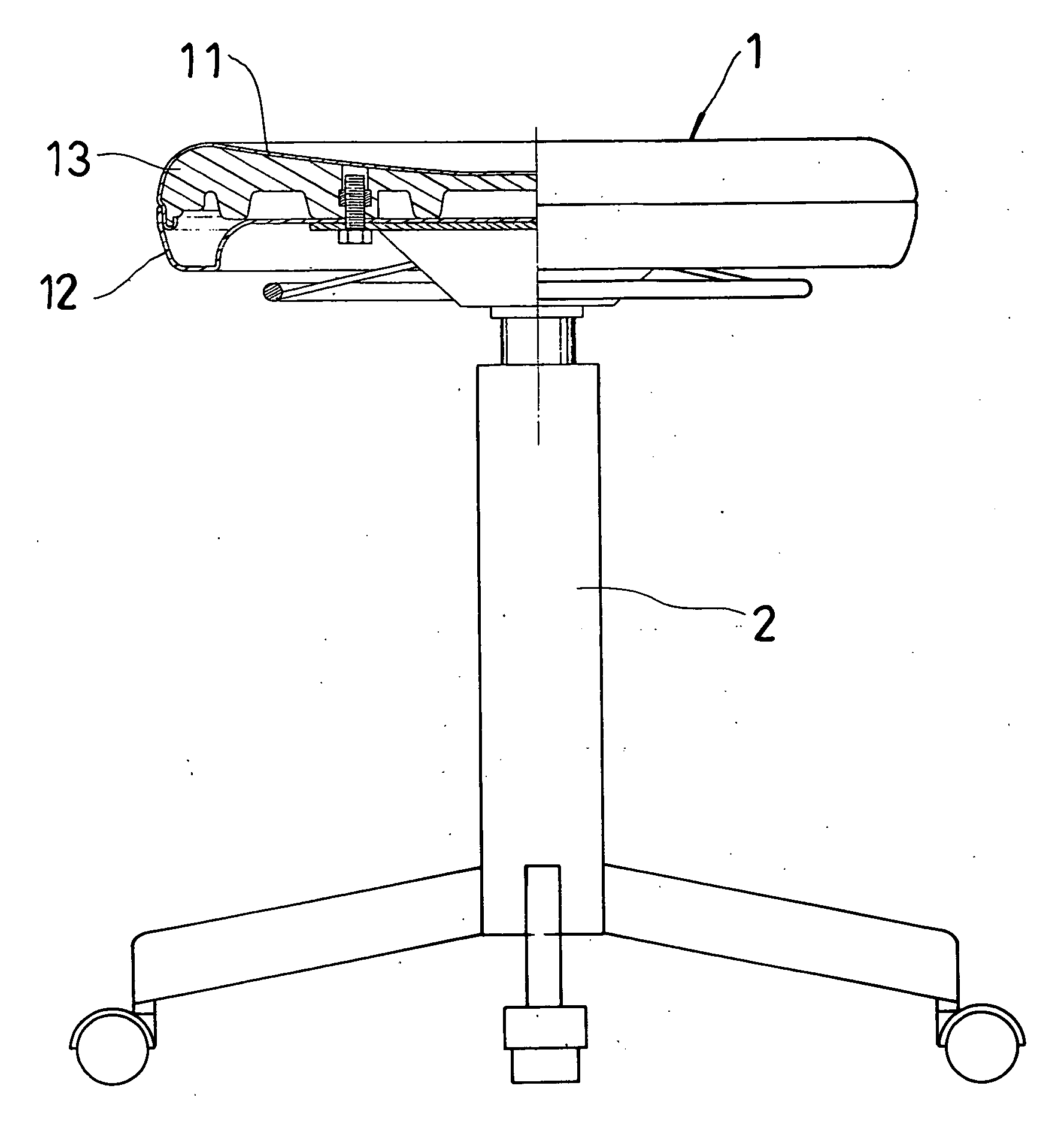

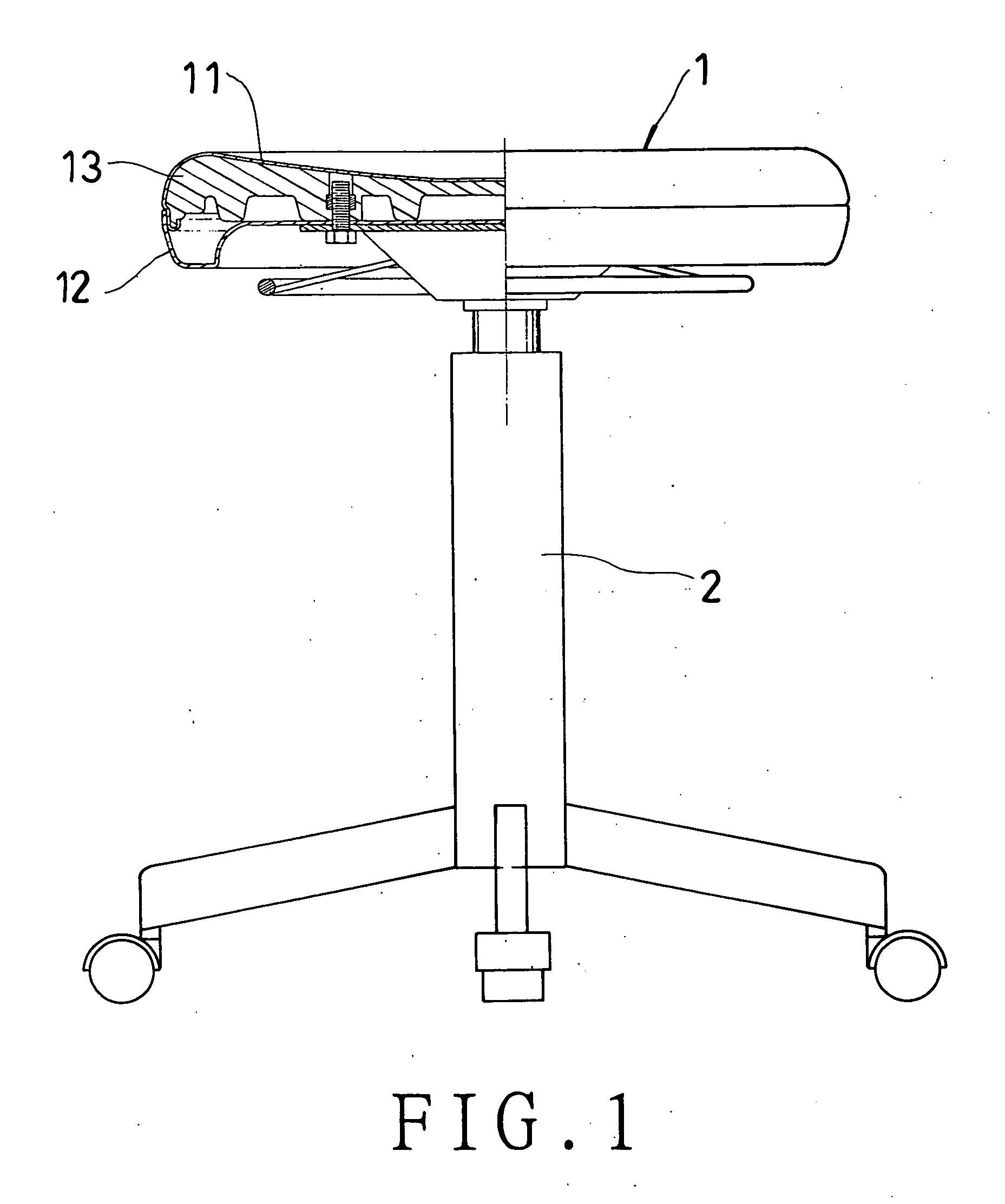

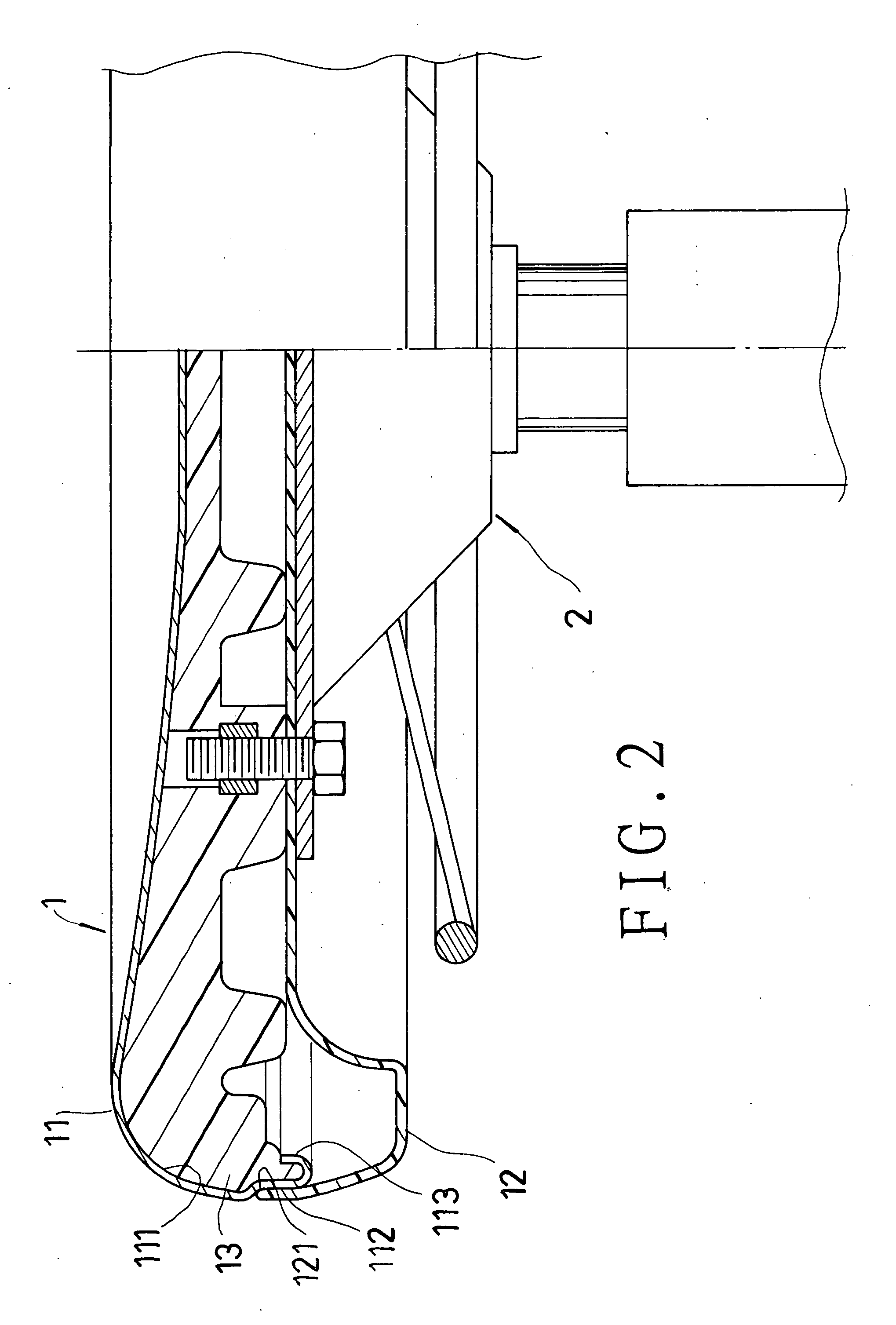

[0013] Referring to FIGS. 1 to 5, a preferred embodiment of a seat 1 of a chair in the present invention includes an upper metallic covering sheet 11, a lower covering sheet 12, and a plastic main body 13. The seat 1 is joined to a chair leg 2 at a lower side thereof.

[0014] The upper metallic covering sheet 11 is substantially in the shape of a bivalve shell valve, which is sealed at one side and has an opening at the other side. Further, the upper metallic covering sheet 11 includes a hollow portion 111.

[0015] The main body 13 is held in the hollow portion 111 of the upper metallic covering sheet 11, and the upper metallic covering sheet 11 is pressed at a lower circumferential portion thereof to form a compressed step-shaped section 112, and the upper metallic covering sheet 11 is curled at a lower end to form an edge sealing section 113.

[0016] The lower covering sheet 12 can be made of metal. Or alternatively, the lower covering sheet 12 can be made of plastic. The lower cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com