Direct-view MEMS display devices and methods for generating images thereon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

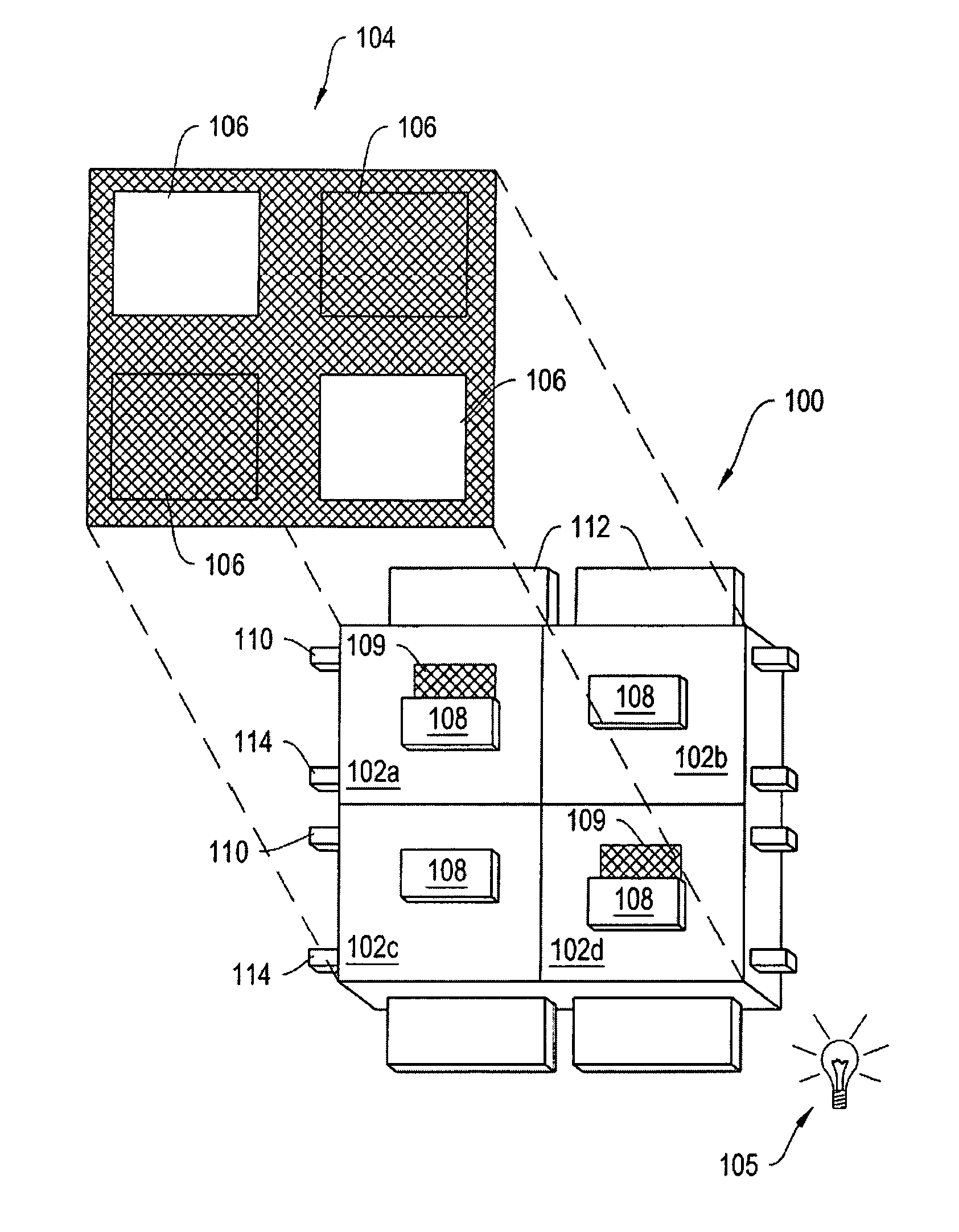

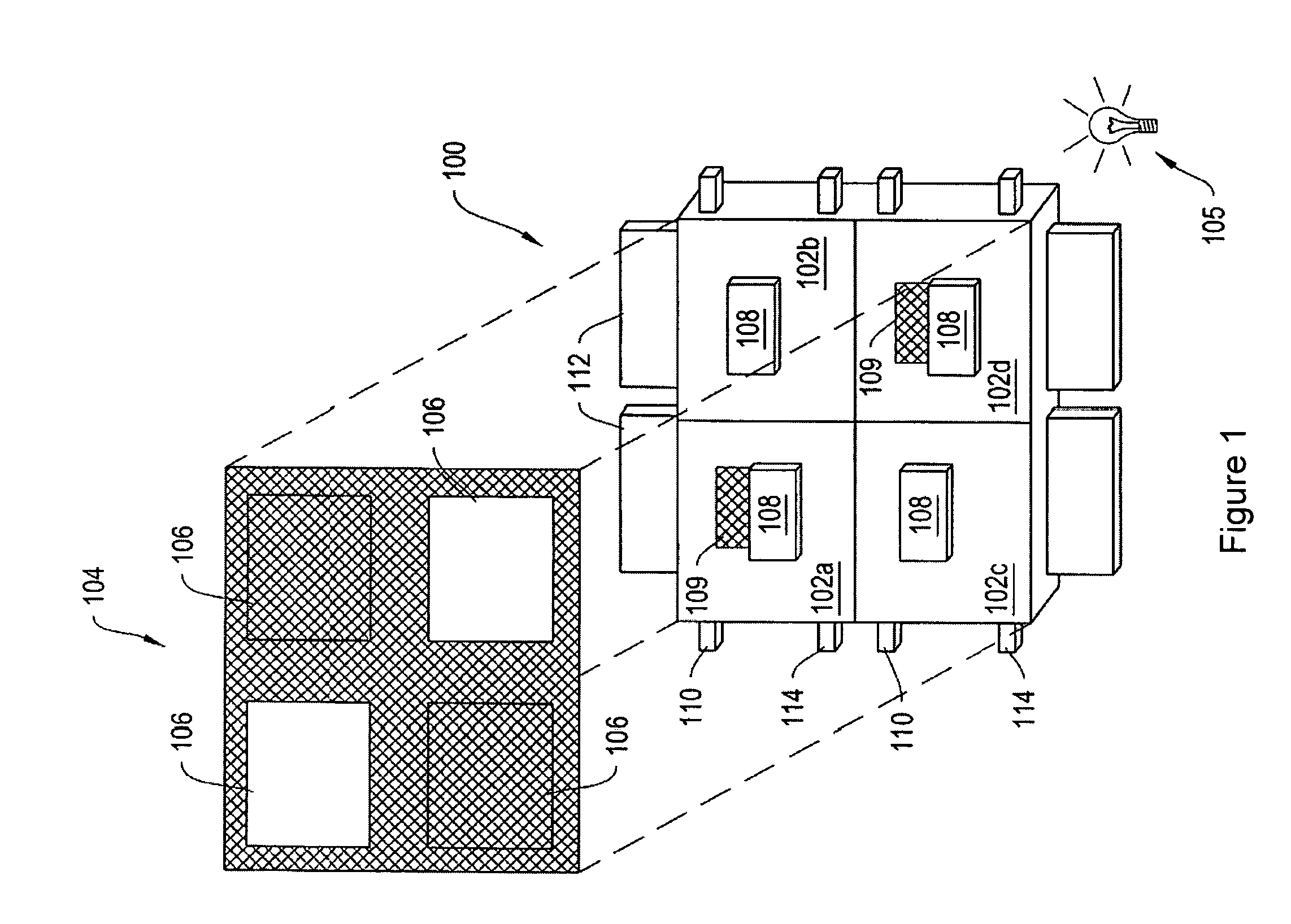

[0057]FIG. 1 is a schematic diagram of a direct-view MEMS-based display apparatus 100, according to an illustrative embodiment of the invention. The display apparatus 100 includes a plurality of light modulators 102a-102d (generally “light modulators 102”) arranged in rows and columns. In the display apparatus 100, light modulators 102a and 102d are in the open state, allowing light to pass. Light modulators 102b and 102c are in the closed state, obstructing the passage of light. By selectively setting the states of the light modulators 102a-102d, the display apparatus 100 can be utilized to form an image 104 for a backlit display, if illuminated by a lamp or lamps 105. In another implementation, the apparatus 100 may form an image by reflection of ambient light originating from the front of the apparatus. In another implementation, the apparatus 100 may form an image by reflection of light from a lamp or lamps positioned in the front of the display, i.e. by use of a frontlight.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com