Apparatus and methods for managing the temperature of a substrate in a high vacuum processing system

Inactive Publication Date: 2007-12-13

VEECO INSTR

View PDF57 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0009]The present invention is directed generally to apparatus and methods for improving the control of the temperature of a supported member, such as a substrate or a pallet carrying one or more substrates, in high vacuum processing systems, such as ion beam etch (IBE) systems. In accordance with an embodiment of the invention, an apparatus is provided for controlling the temperature of a supported member exposed to a treatment that heats the substrate. The apparatus comprises a first member having a surface configured to support the supported member and a second member coupled with the first member. The first member receives heat from the supported member transferred to the surface and the second me

Problems solved by technology

Therefore, the overall product throughput of the system is significantly limited by the cooling capacity of the support fixture.

Other processes, such as reactive ion etching, for forming thin film magnetic heads are tolerant of considerably higher etch rates than ion beam etching, but lack the precision of ion beam etching processes.

Heat conduction between a substrate and a conventional substrate holding fixture using backside heat transfer gas cooling is relatively inefficient in a near vacuum or other low pressure environment quite difficult because heat does not transfer well at these pressures.

For example, the conduction of heat between coextensive surfaces of a substrate fixture and the substrate is slow and inefficient because actual contact on an atomic scale between the surfaces is limited to a small fraction of the coextensive contacting areas.

Despite the cooperation of these cooling techniques, conventional substrate fixtures c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

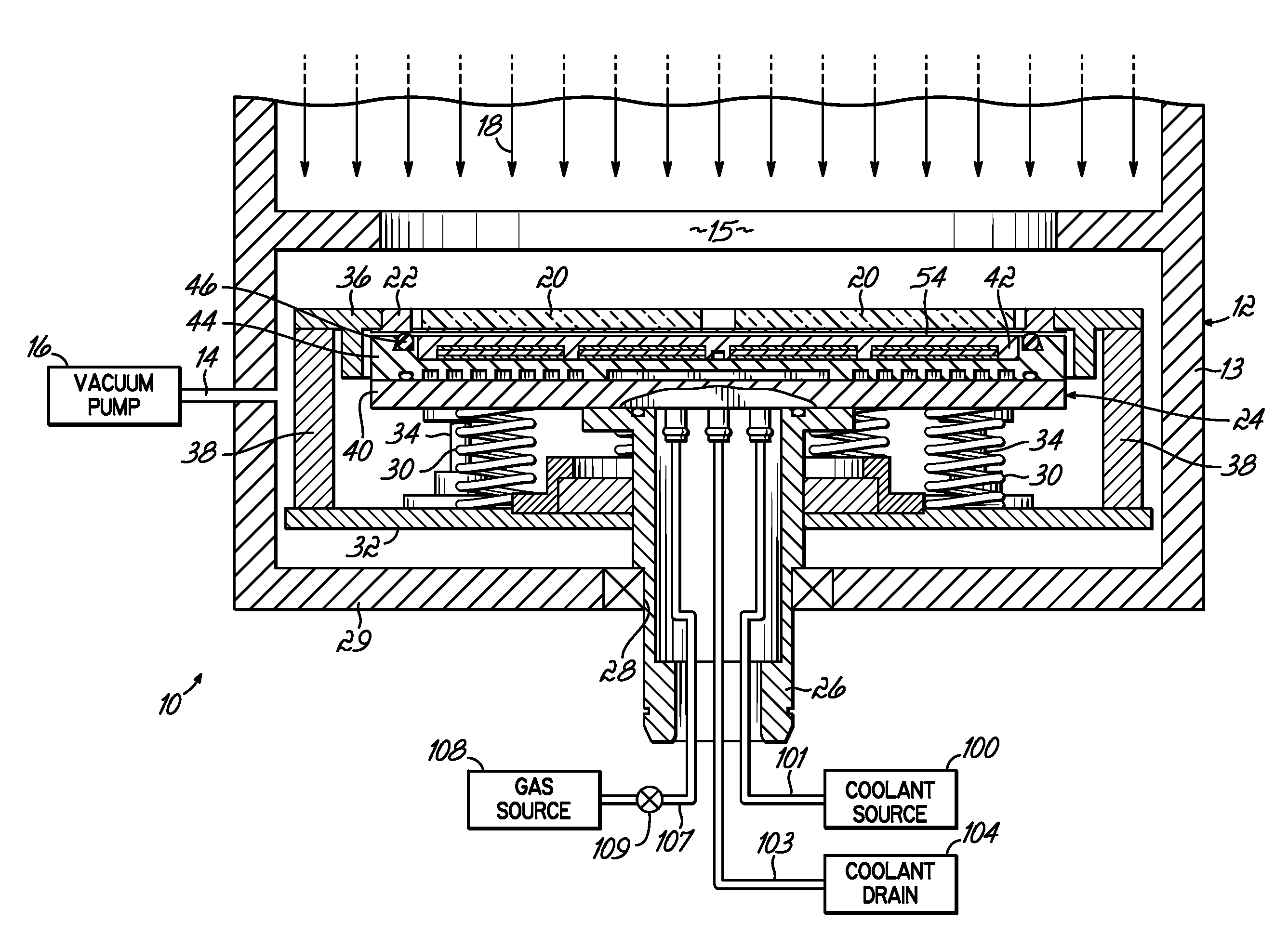

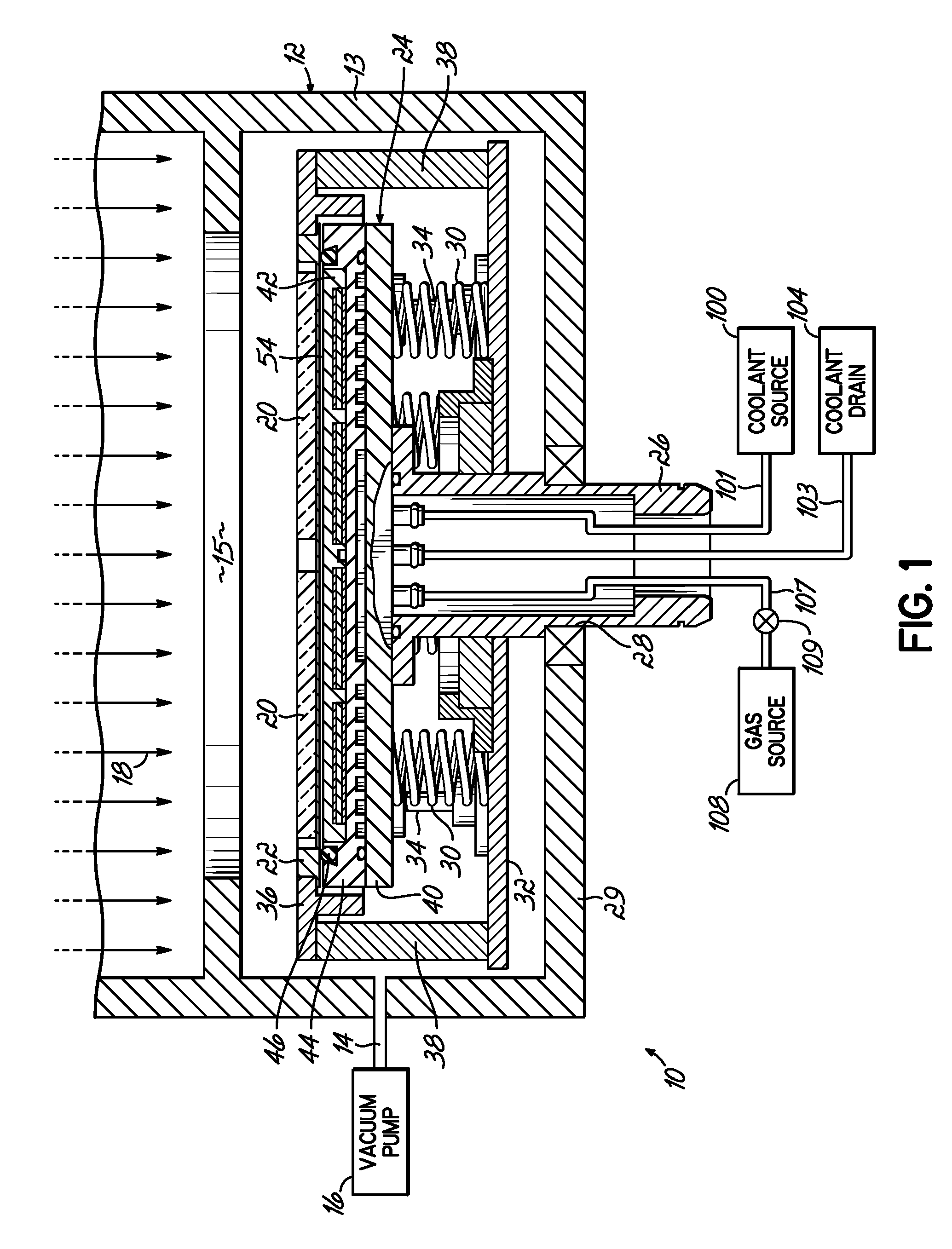

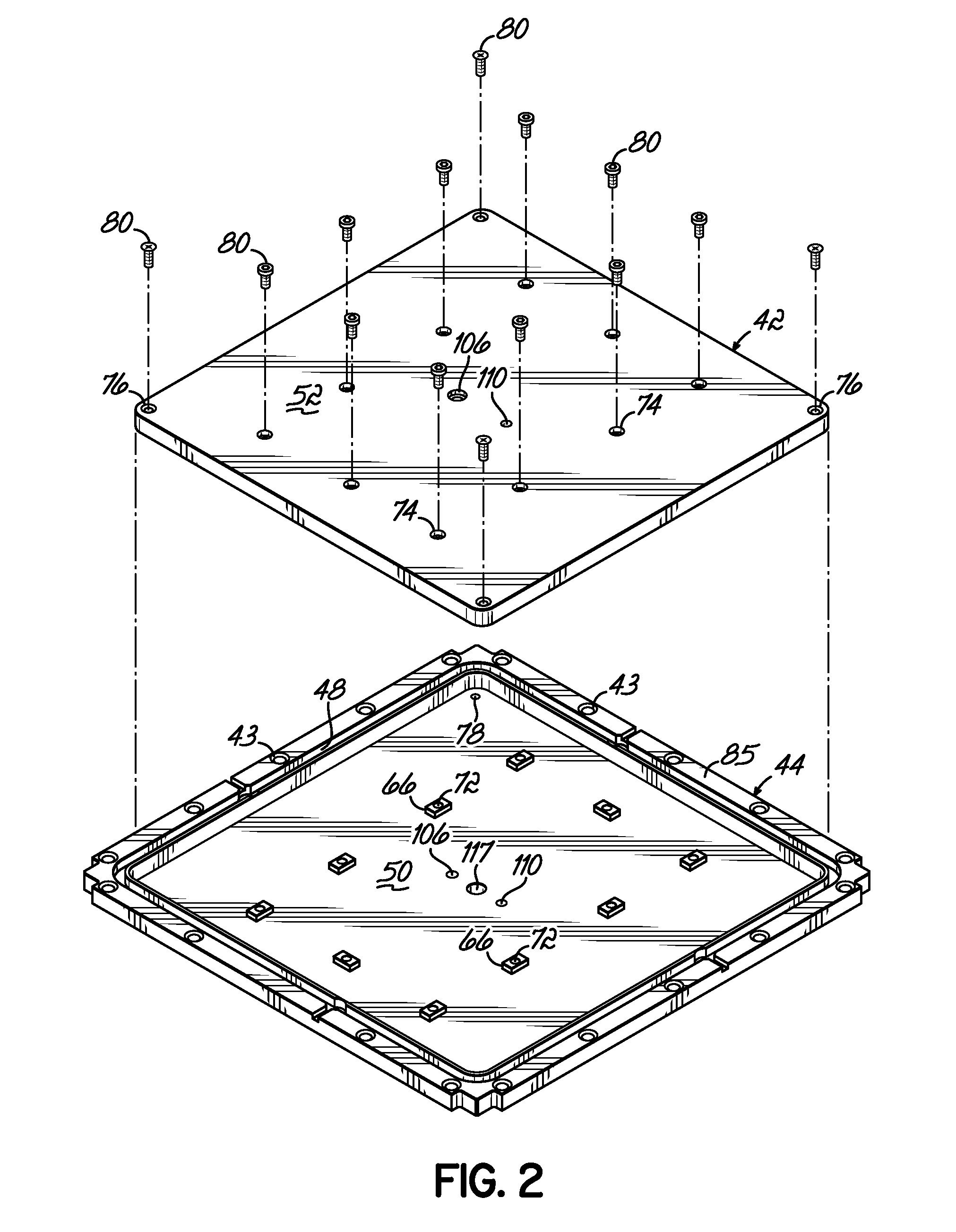

Apparatus and methods for improving the control of the temperature of a supported member, such as a substrate, in high vacuum processing systems, such as ion beam etch (IBE) systems. The apparatus includes thermoelectric devices that transfer heat from a support member supporting the supported member to a liquid-cooled heat exchange member to regulate the temperature of the support member. The method includes cooling the support member with thermoelectric devices that transfer the heat to the liquid-cooled heat exchange member.

Description

FIELD OF THE INVENTION[0001]The invention relates generally to high vacuum processing systems and methods and, in particular, to apparatus and methods for controlling a temperature of a supported member, such as a substrate or one or more substrates supported on a pallet, during ion beam processing in a high vacuum processing system.BACKGROUND OF THE INVENTION[0002]Substrates are supported in vacuum chambers of high vacuum processing systems for treatment by processes such as ion beam etching, reactive ion etching, and plasma etching that remove a material layer from the substrates, processes such as ion beam deposition, physical vapor deposition, and chemical vapor deposition that deposit a material layer on the substrates, and other processes that modify a substrate surface property. In such surface treatment processes, the substrate rests on, or is secured to, a substrate support fixture, such as a platen, a chuck, or an electrode. During processing, a large amount of thermal ene...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25B21/02F25D23/12

CPCF25B21/02H01L21/67248H01L21/67109H01L21/67103

Inventor LUSE, TODD ARTHURFREMGEN, ROGERMILLER, WILLIAM J.CELARU, ADRIAN

Owner VEECO INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com