Transportation machine with energy absorbing structure

a technology of transporting machine and energy-absorbing structure, which is applied in the direction of buffer cars, railway bodies, axle-box lubrication, etc., can solve the problems of large impact on the railway vehicle, the possibility of collision with an unexpected material object during operation, and the inability to effectively dispose of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

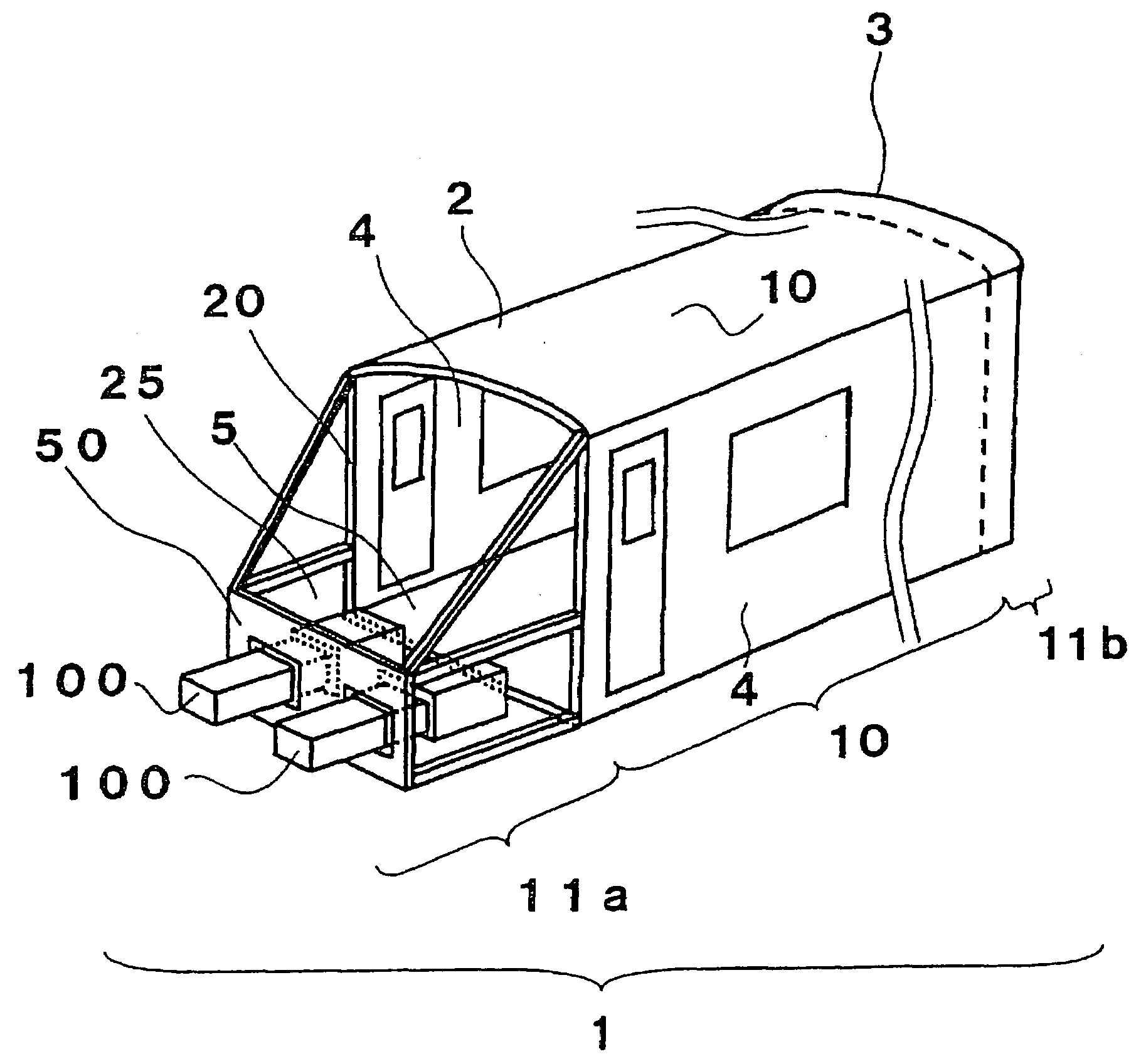

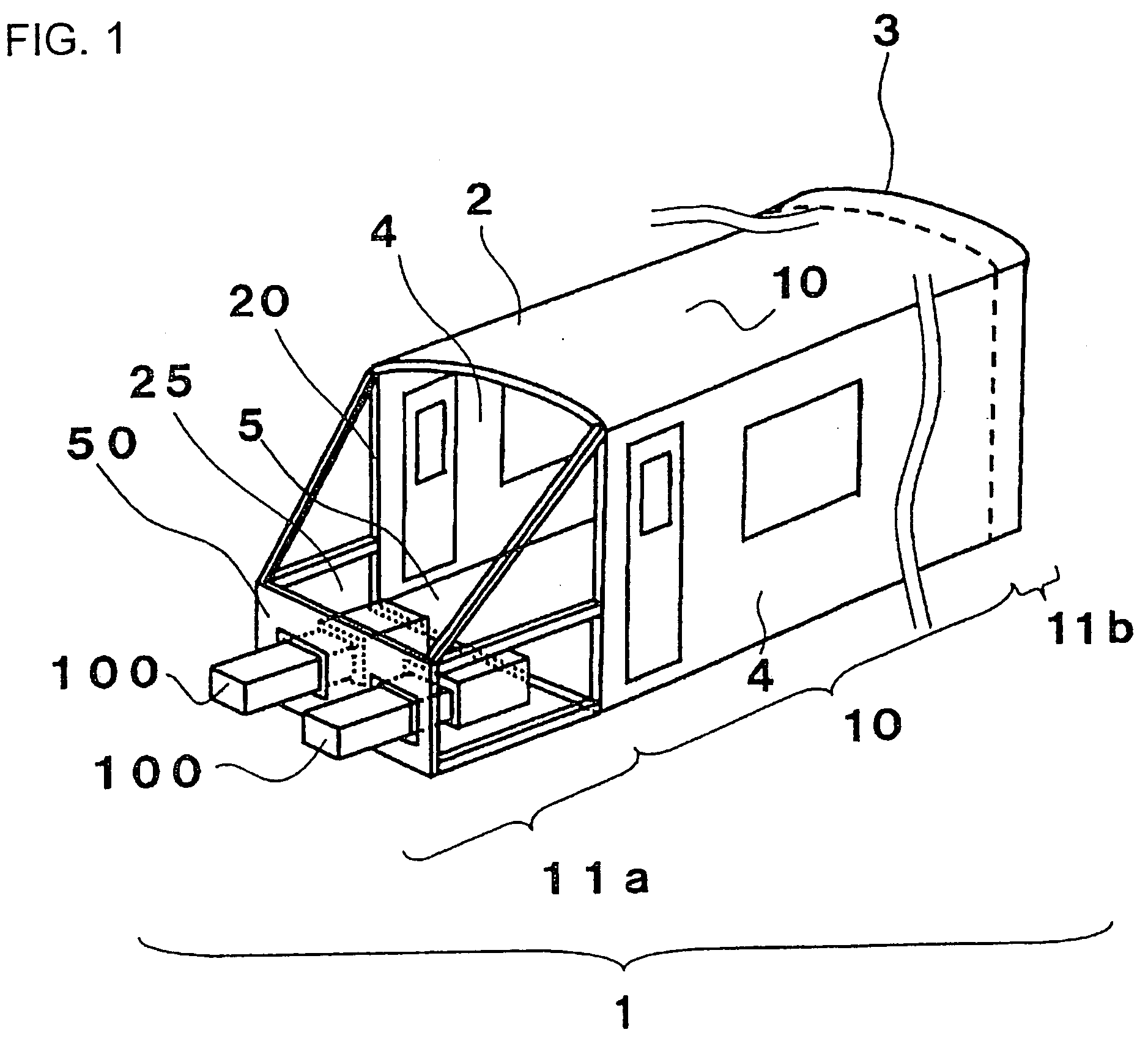

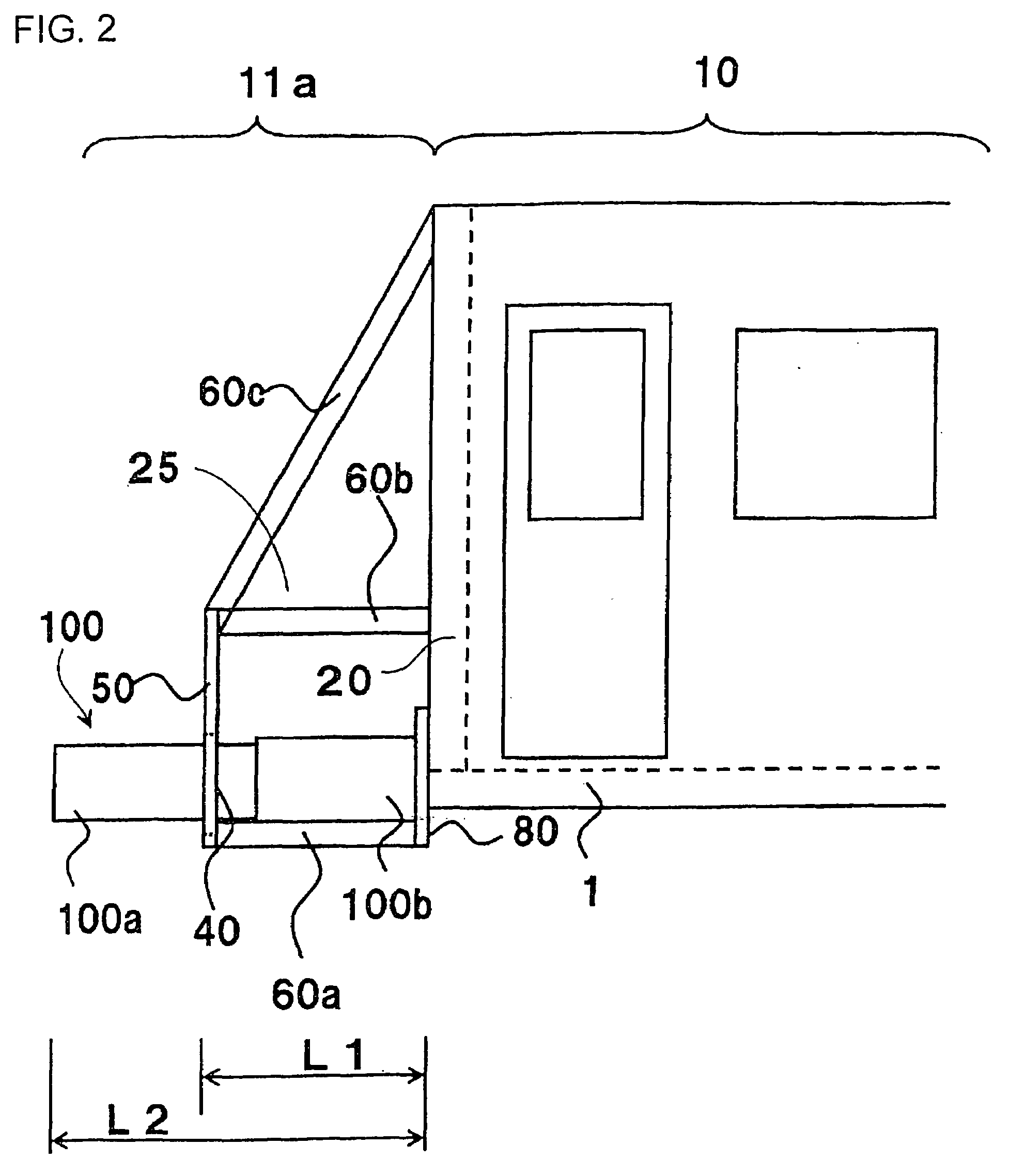

[0027]A first embodiment in the case where the present invention is applied to a railway vehicle body structure when a transportation machine is a railway vehicle will be described with reference to FIGS. 1 to 4.

[0028]First, a structure of the railway vehicle body structure will be described with reference to FIG. 1. A railway vehicle body structure 1 is constructed by a roof body structure 2 which forms a roof, end body structures 3 which form surfaces for closing both ends with respect to a vehicle body longitudinal direction, side body structures 4 which form left and right surfaces with respect to the vehicle body longitudinal direction, and an underframe 5 which forms a floor surface. The underframe 5 has high rigidity against a compression load in the longitudinal direction. Windows and openings for entrance / exit are formed in the side body structure 4. The railway vehicle body structure 1 having such a basic structure has a survival zone 10 which protects the lives of passeng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com