Wind Turbine, a Method for Assembling and Handling the Wind Turbine and Uses Hereof

a technology for wind turbines and wind power generators, which is applied in the field of wind power generators, can solve the problems of delicate electrical equipment, easy damage to the unit, and difficulty in handling and transporting the uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

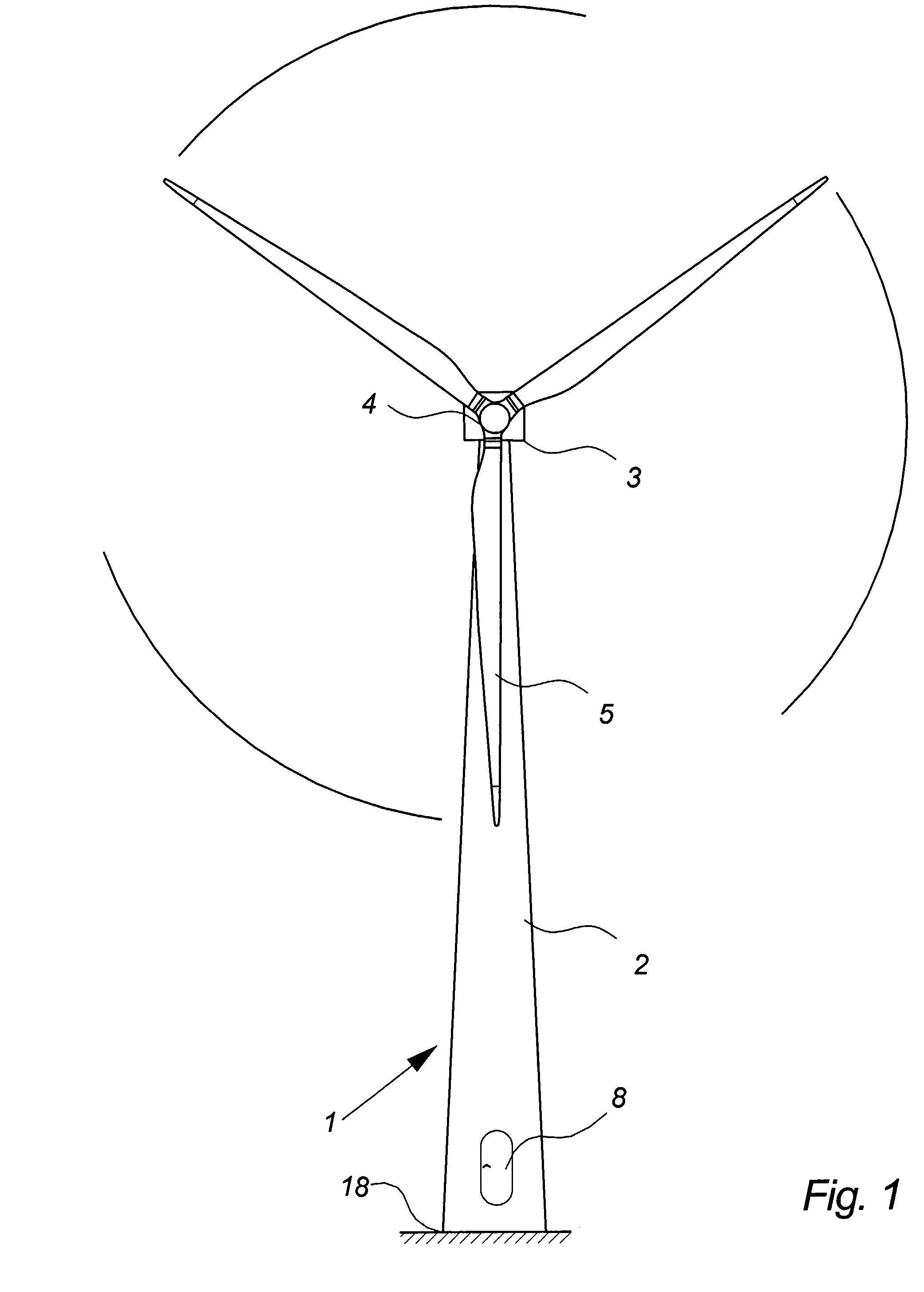

[0076]FIG. 1 illustrates a modern wind turbine 1 mounted on the foundation 18 comprising a tower 2 with a door 8 and a wind turbine nacelle 3 positioned on top of the tower 2. The wind turbine rotor 4, comprising three wind turbine blades 5, is connected to the nacelle 3 through the low speed shaft which extends out of the nacelle 3 front.

[0077] The different components of a wind turbine 1 are usually transported separately to the site of mounting and assembled there e.g. the different tower sections, the nacelle 3 and the wind turbine blades 5.

[0078] The wind turbine may e.g. be an off-shore wind turbine.

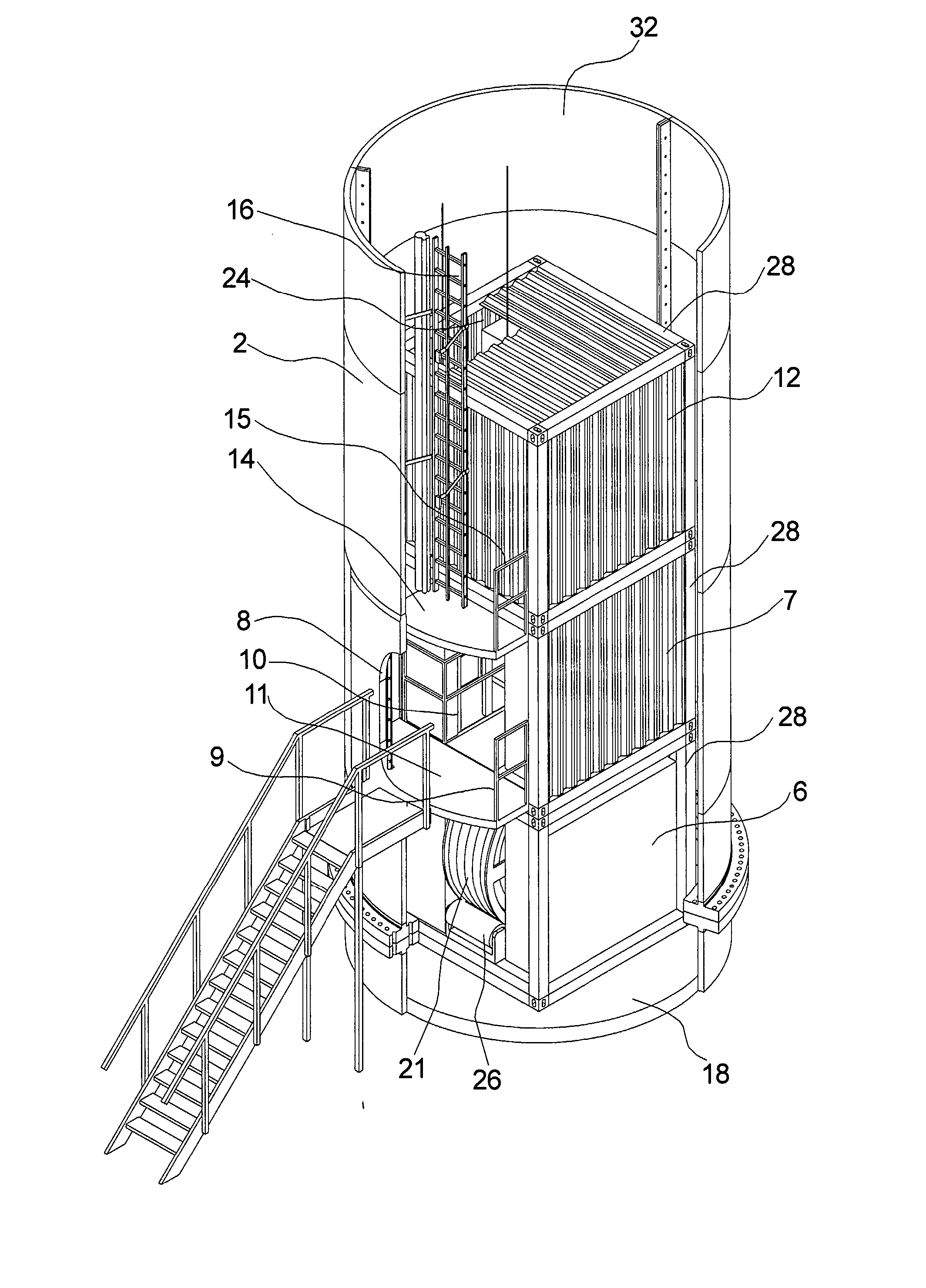

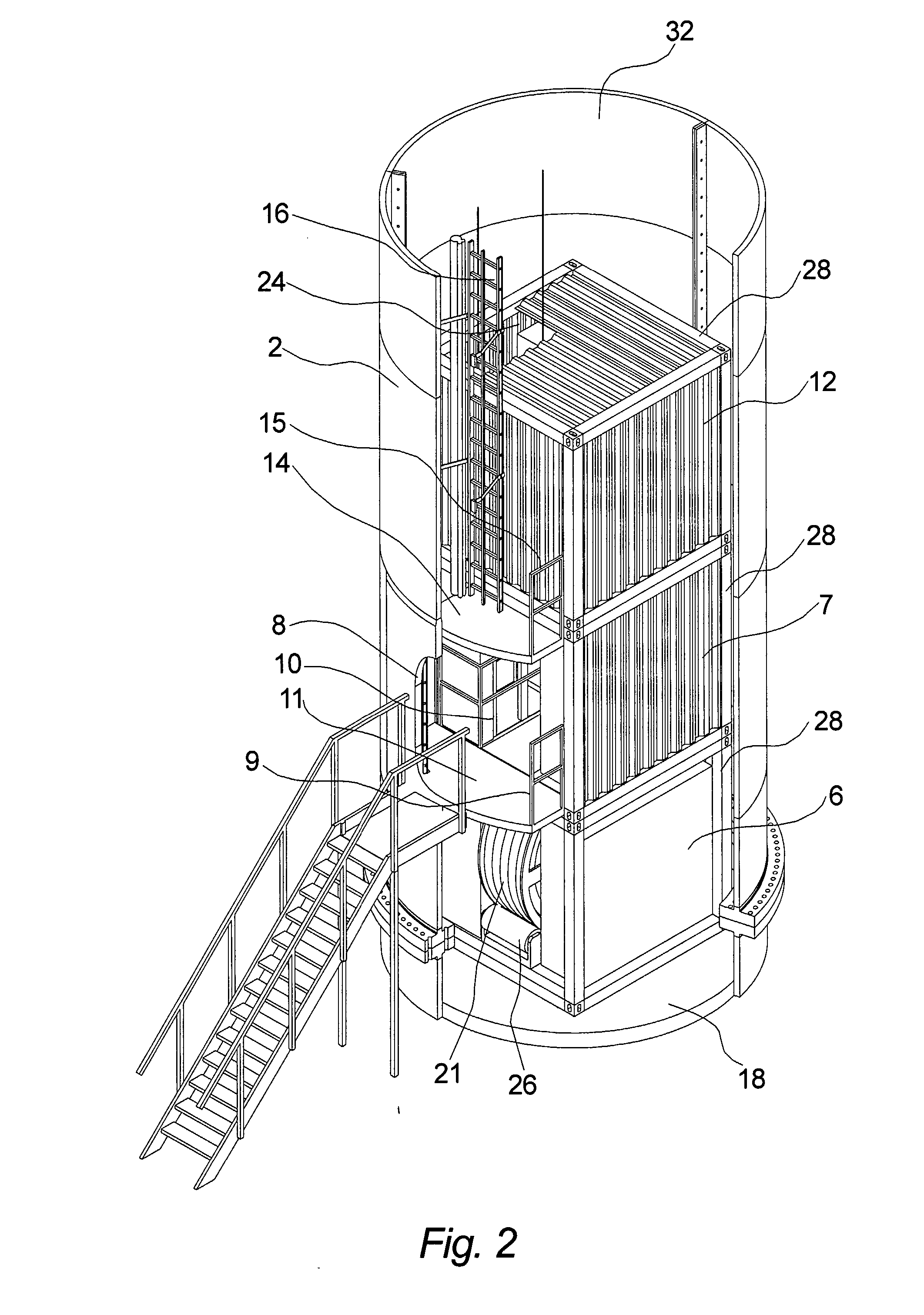

[0079]FIG. 2 illustrates in perspective a wind turbine tower 2 with a section cut-off so it is possible to see inside the tower 2. In this embodiment of the invention three equipment modules are placed on the wind turbine foundation 18 inside the tower 2. A cable module 6 is positioned at the bottom and is somehow connected to the foundation 18. The cable module 6 at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com