Apparatus for performing well work on floating platform

a technology for floating platforms and accessories, applied in the direction of sealing/packing, drilling pipes, drilling/well accessories, etc., can solve problems such as problems such as drilling, completing, and producing problems, and achieve the effect of improving the safety and safety of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

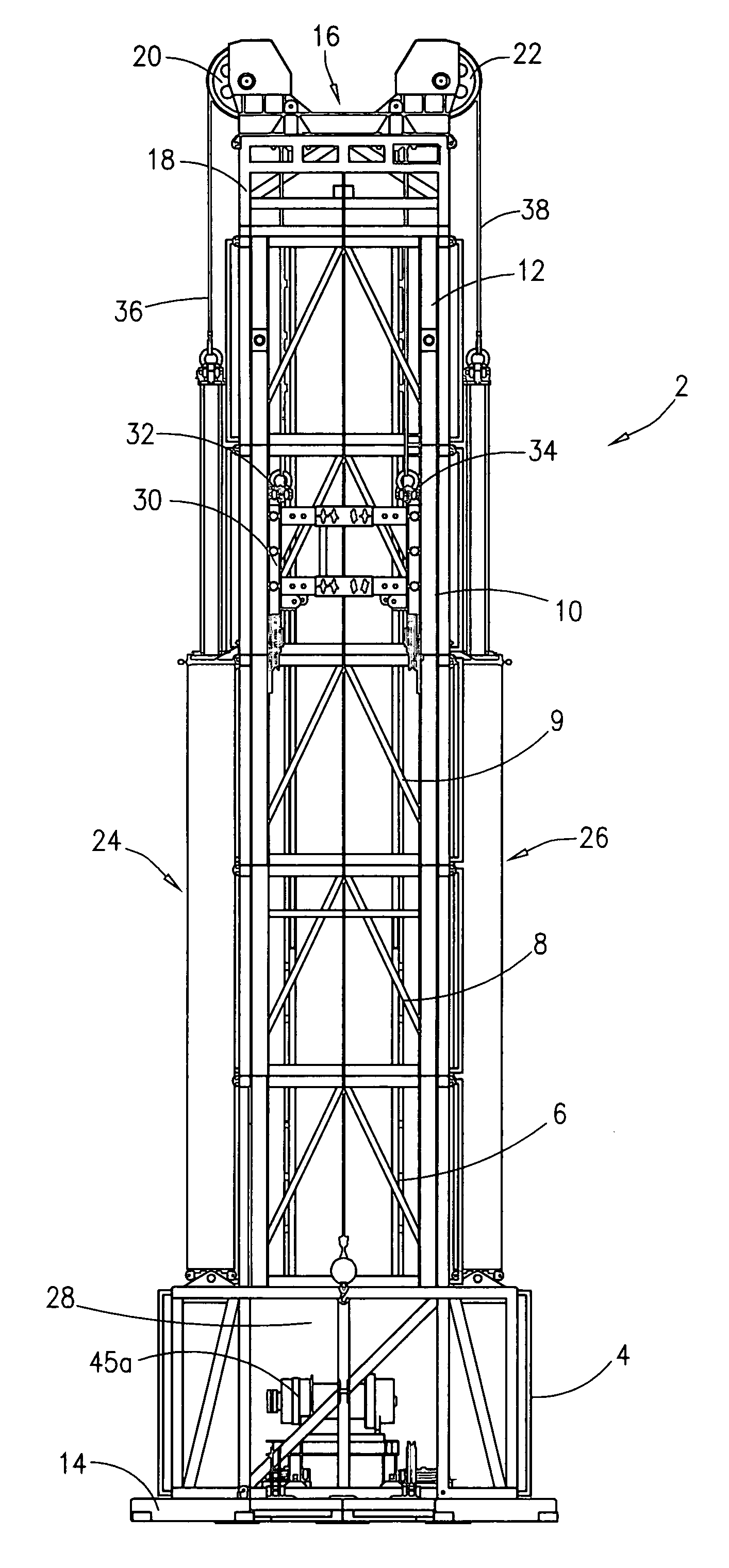

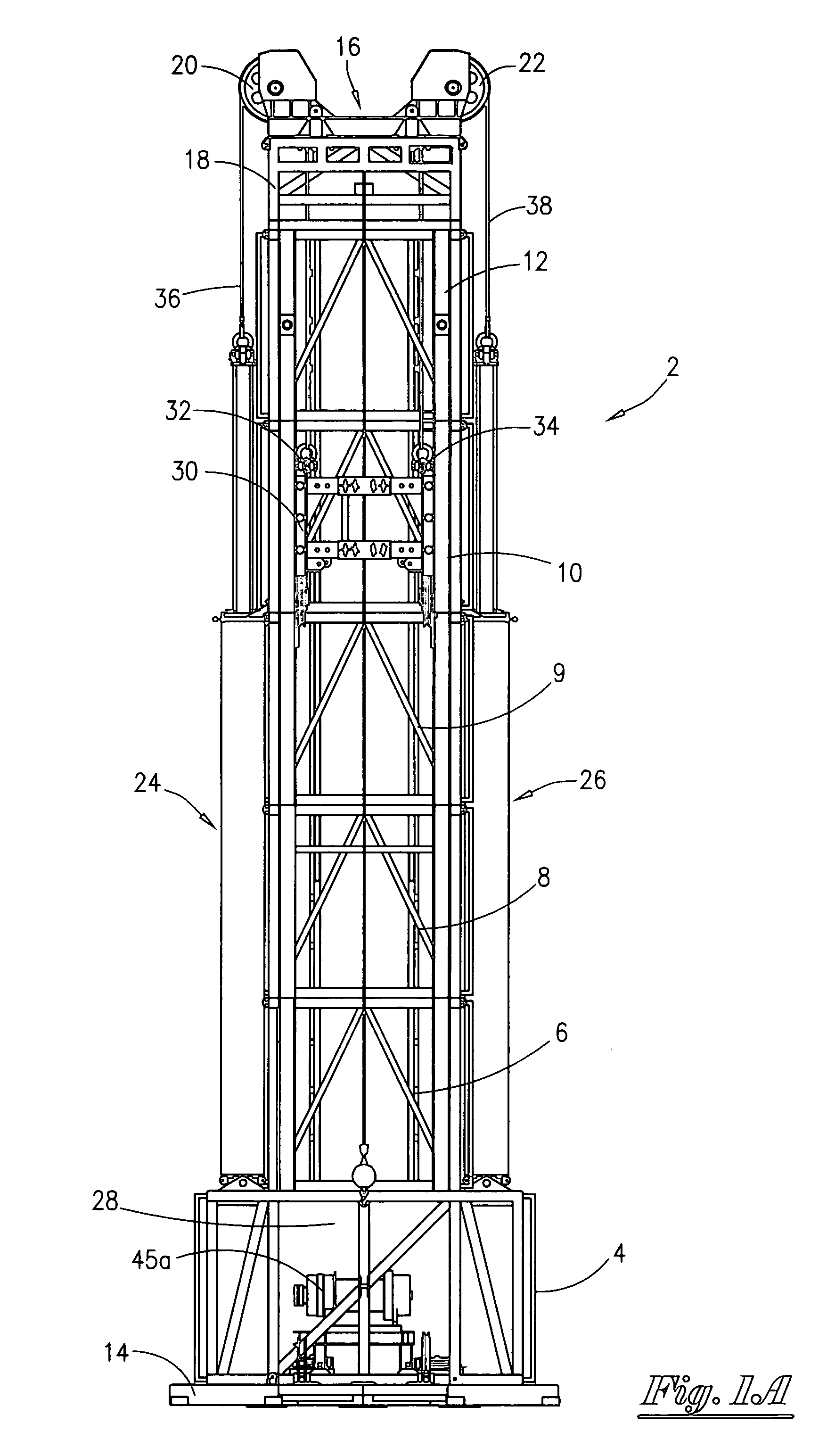

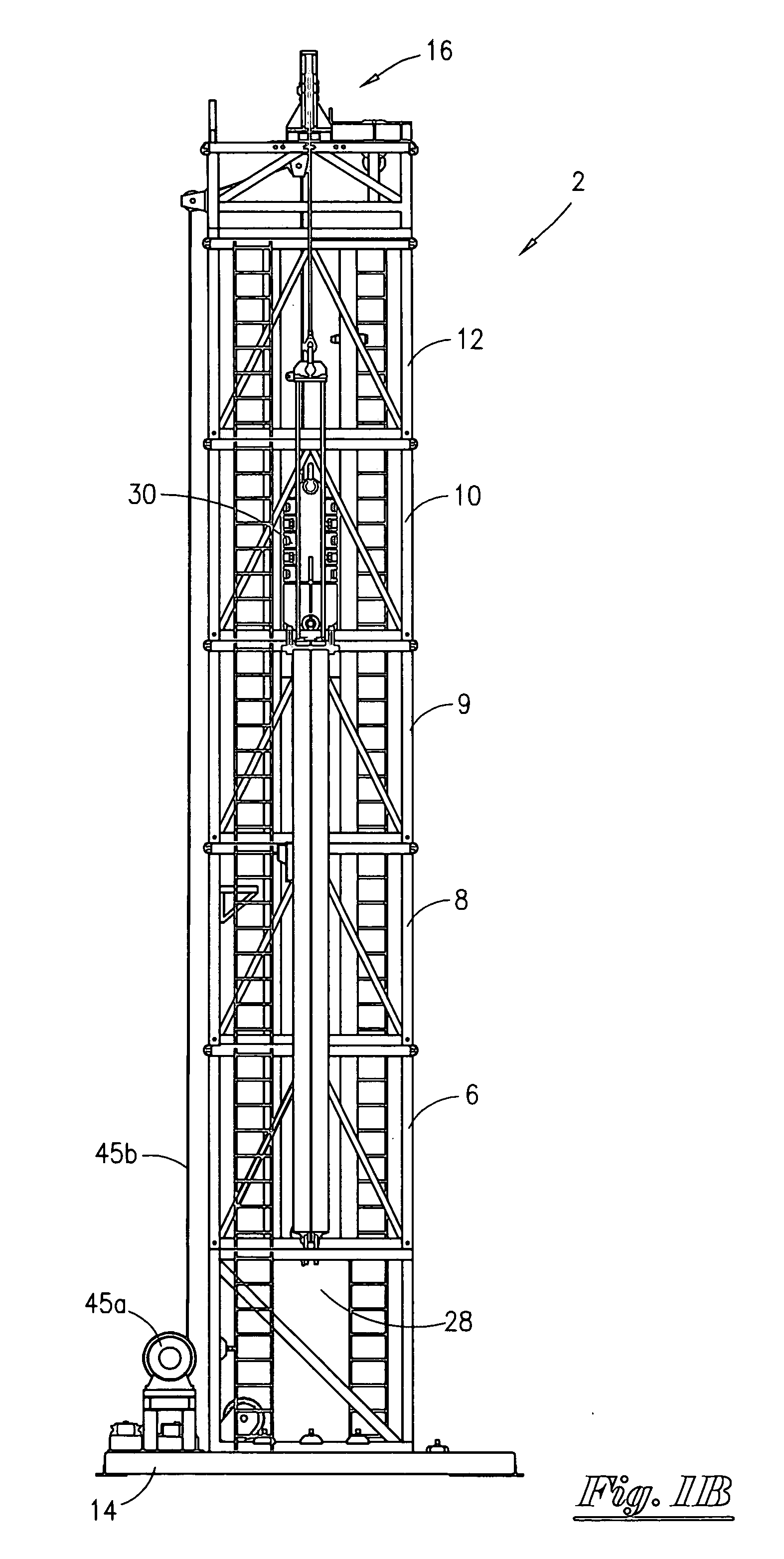

[0029]Referring now to FIG. 1A, a front general layout view of the most preferred embodiment of the well intervention frame assembly 2 will now be described. In the most preferred embodiment, the frame assembly 2 consist of a series of modular frames, sometimes referred to as a tower. As shown in FIG. 1A, the modular frames can be stacked one on top of the other in order to reach a specific height. FIG. 1A depicts the base frame 4, the modular frame 6, the modular frame 8, the module frame 9, the modular frame 10, and the modular frame 12. The modules are commercially available from Devin International Inc. under the name Track Stack Jr. Generally, the individual modular frames have three (3) vertical sides, and wherein one side is open in order to allow a window for entry (sometimes referred to as a working window area). As seen in FIG. 1A, the base frame 4 has a larger footprint (i.e. larger width) in order to better distribute the vertical load which leads to stability of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com