Weight adjustable golf club head

a golf club head and adjustable technology, applied in the field of golf club heads, can solve the problems of affecting the fixation effect, so as to achieve the effect of enhancing the fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

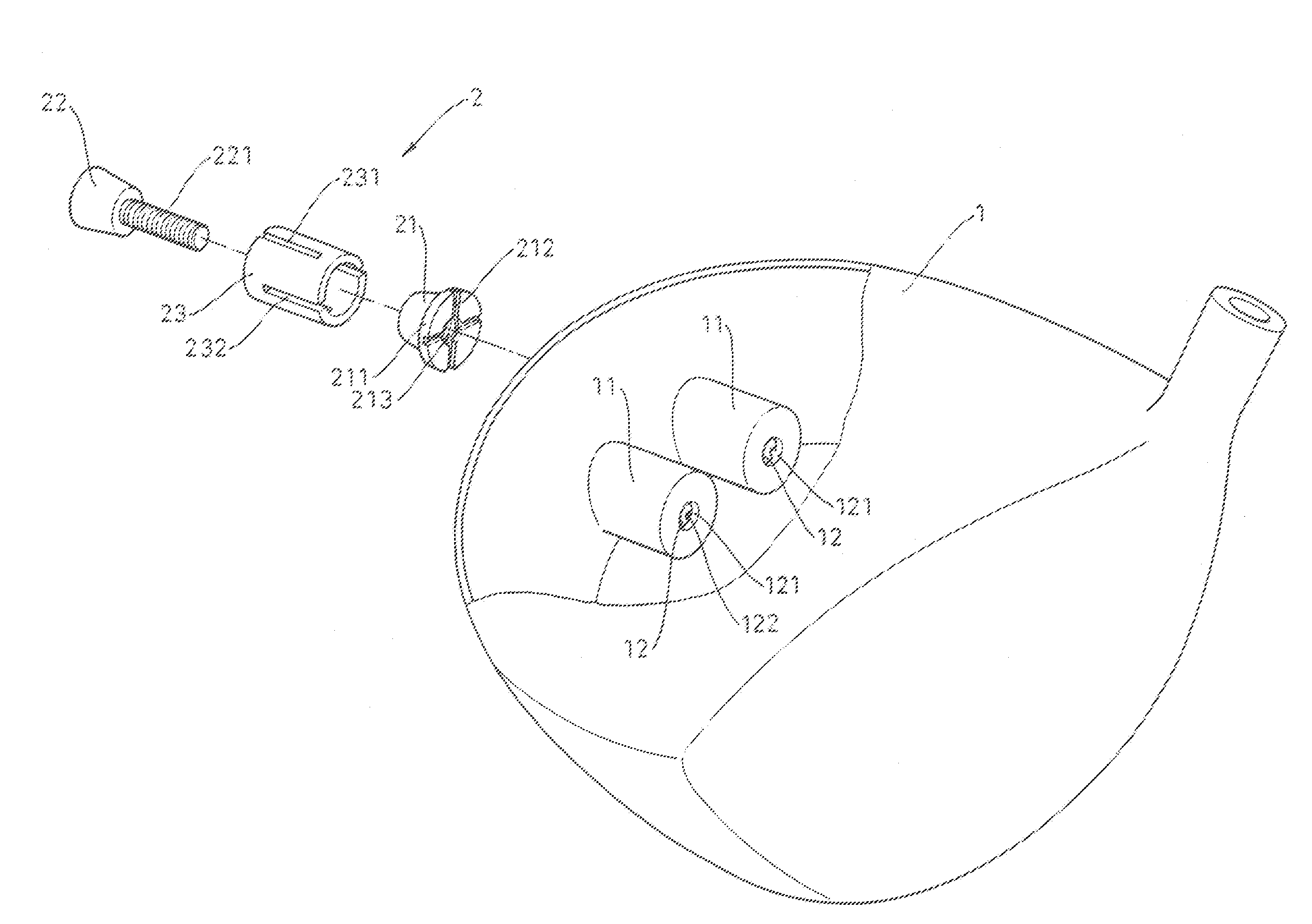

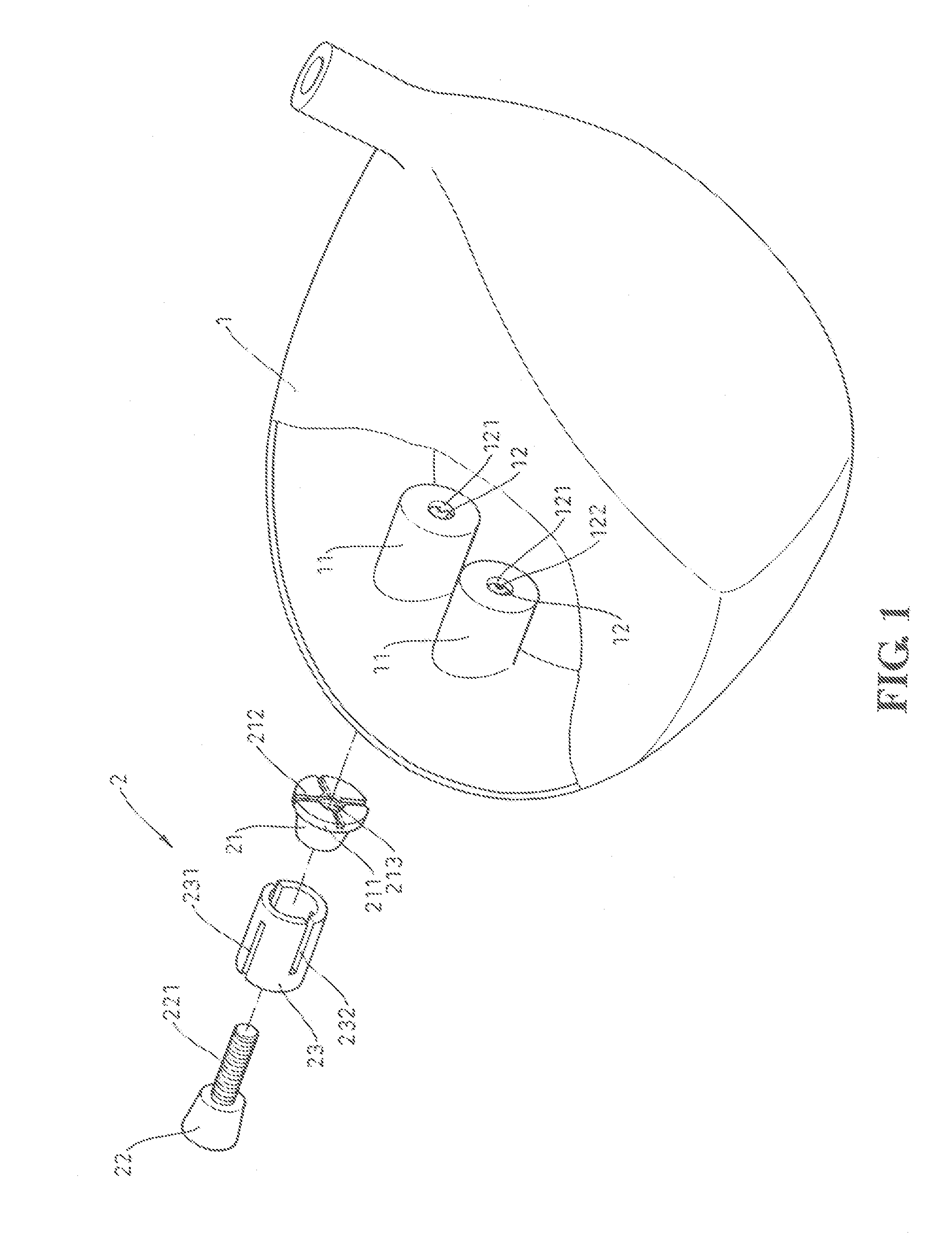

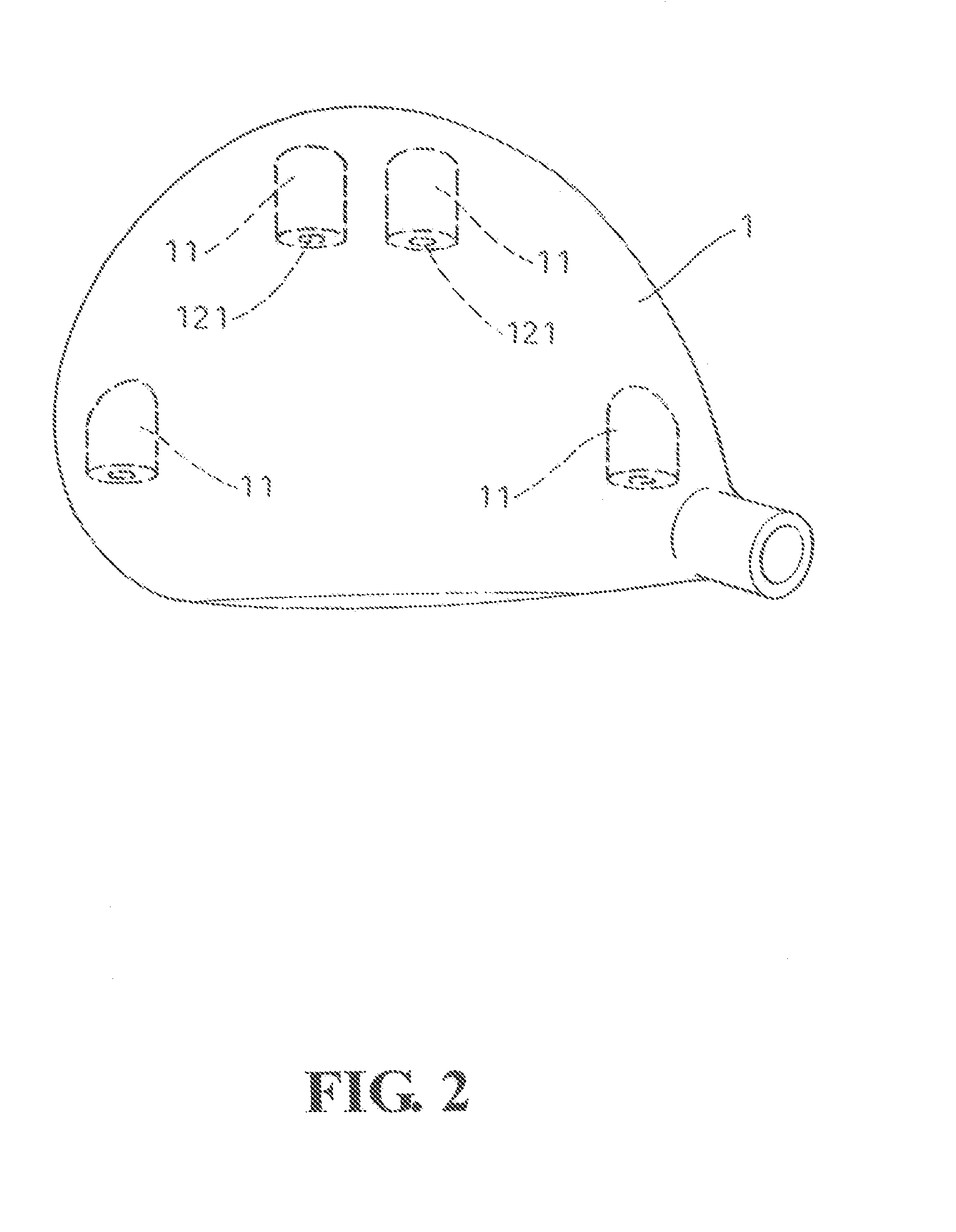

[0016]As shown in FIGS. 1 and 2, a club head 1 according to the present invention has a number of cylindrical blind holes 11 of appropriate depths into the interior of the club head 1 configured on the back surface (i.e., the curved surface opposite to the hitting surface of the club head 1) with appropriate spacing among them. Each of the blind holes 11 therefore provides a storage space 12 for the accommodation of a weight member 2.

[0017]The weight member 2 contains a tubular weight element 23, and a fastening element 22 and a seat element 21 plugged into the two ends of the weight element 23, respectively. The diameter of the weight element 23 is slightly smaller than the aperture of the blind hole 11 so that the weight element 23 can be slid into the blind hole 11. Along the circumference of the weight element 23, a member of through slits 231 are provided along the axial direction from a first end towards the other, second end (but not reaching the second end). Similarly, a num...

second embodiment

[0022]As shown in FIG. 6, a club head 1A according to the present invention has the blind holes 1A1 with longer depths than those of the previous embodiment. Inside the storage space 1A2 of each blind hole 1A1, two opposing slots 1A23 and 1A24 are provided along the axial direction and along the inner wall of the blind hole 1A1. Correspondingly, two radially protruding tenons 2A14 and 2A15 are provided on the rim of the base 2A11 of the seat element 2A1. As such, the seat element 2A1 is prevented from rotation when the fastening element 2A2 is screwed. In the present embodiment, there are multiple fastening elements 2A2, each having a threaded rod 2A21 of a specific length. When a particular fastening element 2A2 is used and screwed to join the seat element 2A1, the threaded rod 2A21 is able to run through the through channel 2A13 until its tip reaches the bottom of the blind hole 1A1. In the process, again, the slits 2A31 and 2A32 allows the two ends of the weight element 2A3 to ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com