Fluid Coupling Assembly for a Dishwasher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

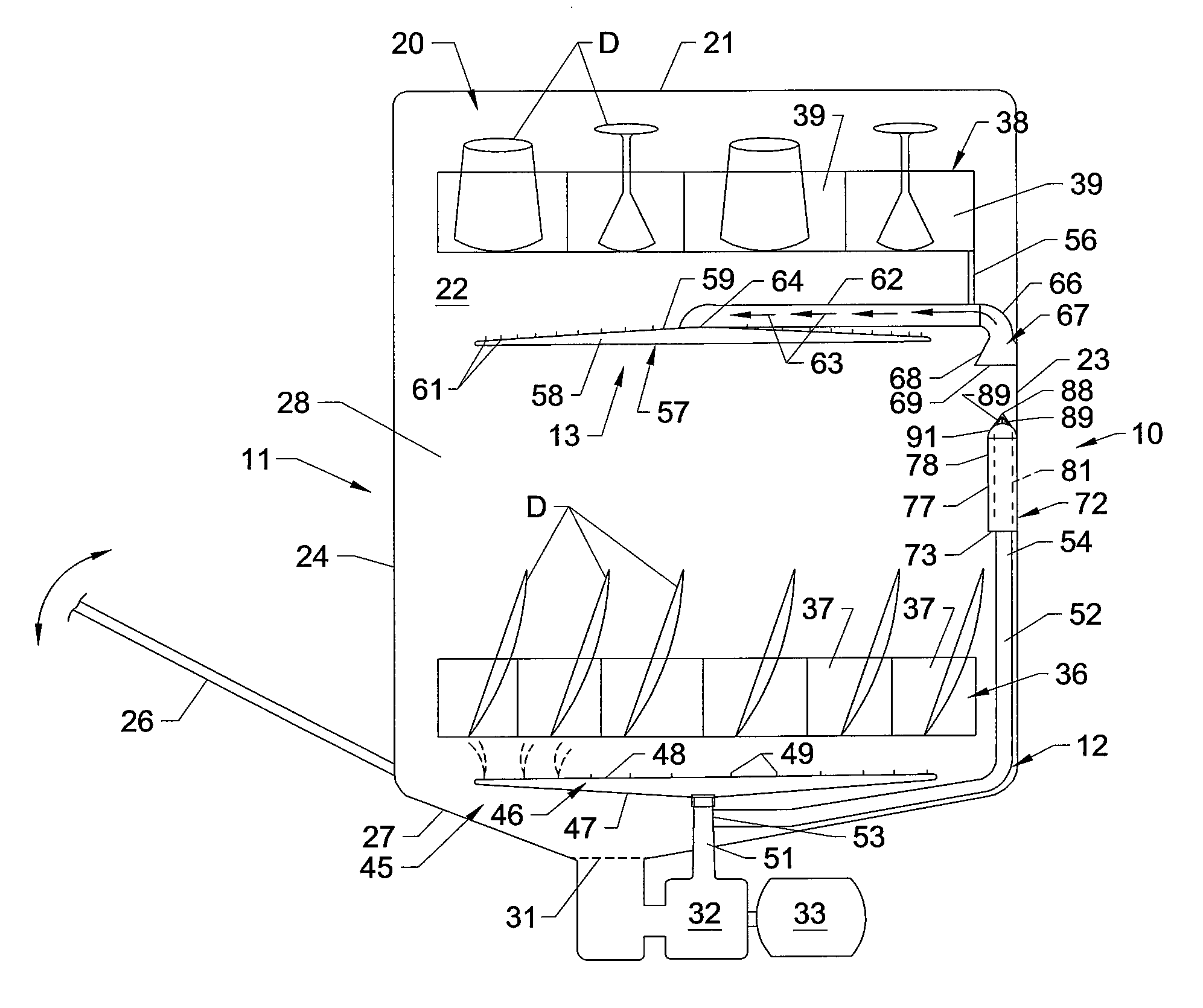

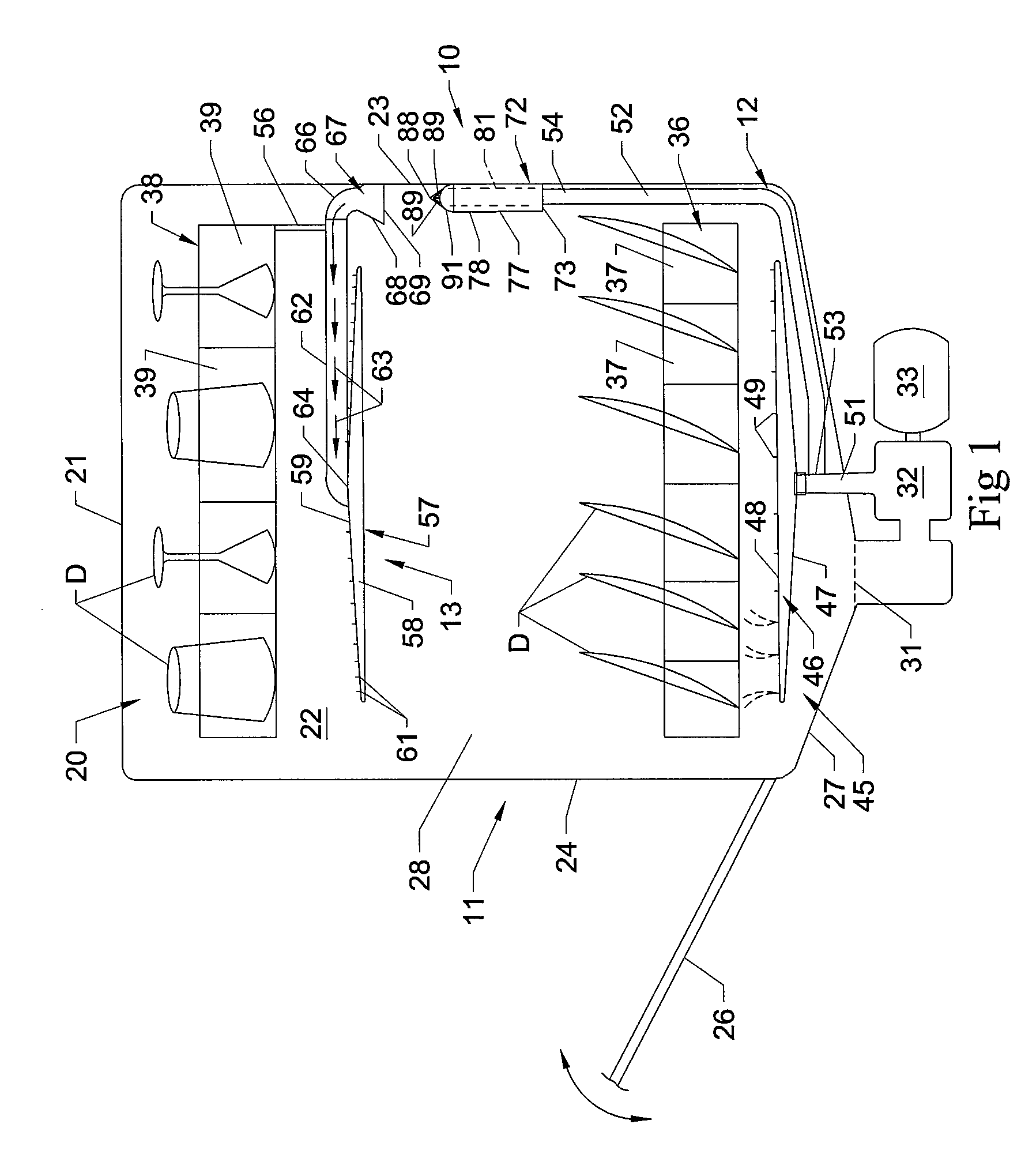

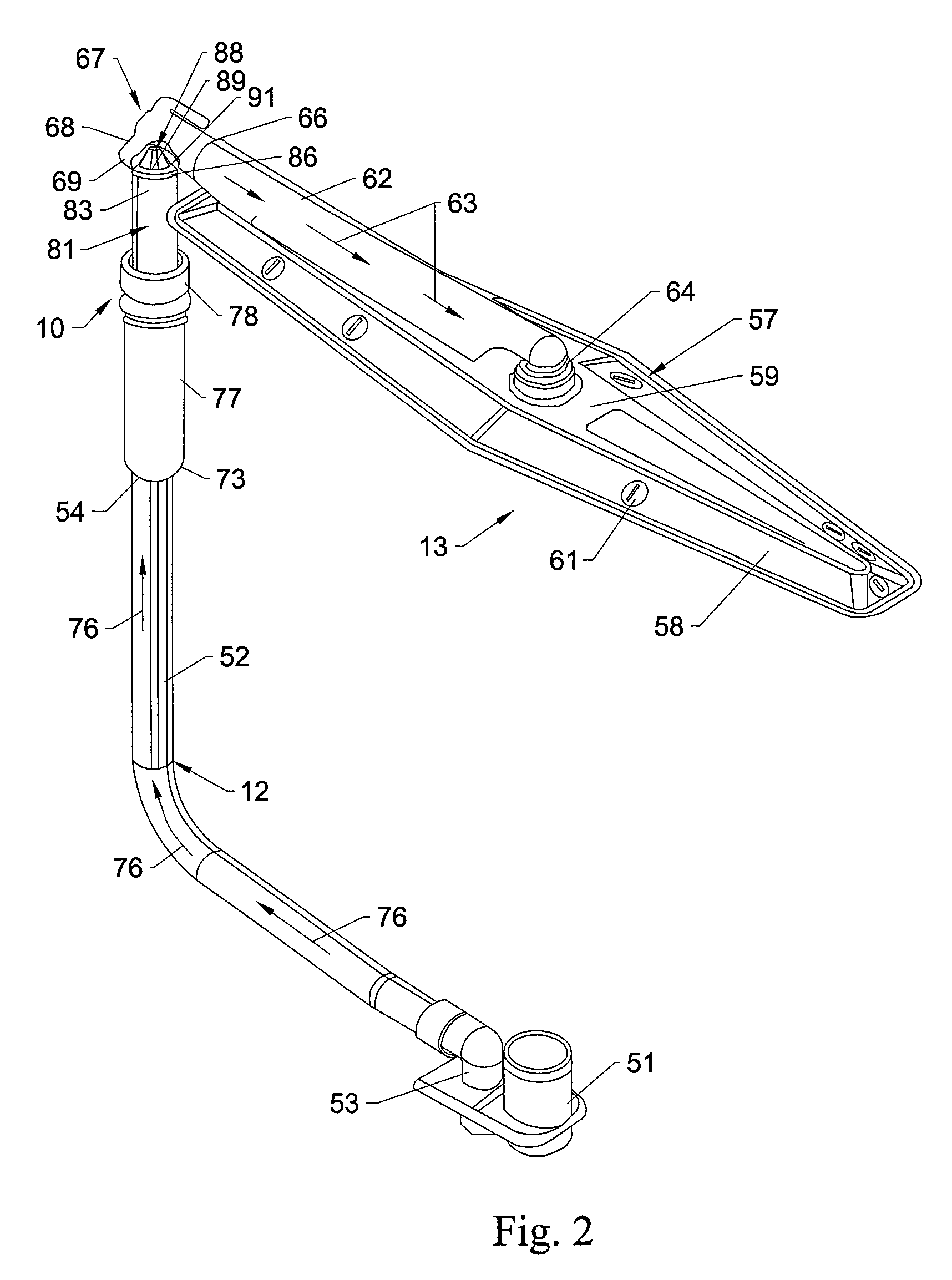

[0018]Referring now to the drawings in which like numerals indicate like parts throughout the several views, as shown in FIG. 1, the present invention generally relates to a flexible fluid coupling assembly 10 for use in a dishwasher 11 for releasably coupling or connecting a wash fluid supply 12 to an upper spray arm assembly 13 of the dishwasher 11. The fluid coupling assembly 10 of the present invention is designed to facilitate and ensure consistent formation of a sealed, substantially fluid-tight connection between the wash fluid supply and the upper spray arm assembly of the dishwasher during a washing operation, with the fluid coupling assembly being automatically disconnected from the upper spray arm assembly when the flow of washing fluid is shut off, so as not to interfere with the loading and unloading of dishware D within the dishwasher, and without reducing the amount of useable space within the dishwasher for loading dishware D therein.

[0019]As generally illustrated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com