Trolley with tractor drive for use in curved enclosed tracks and system including the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

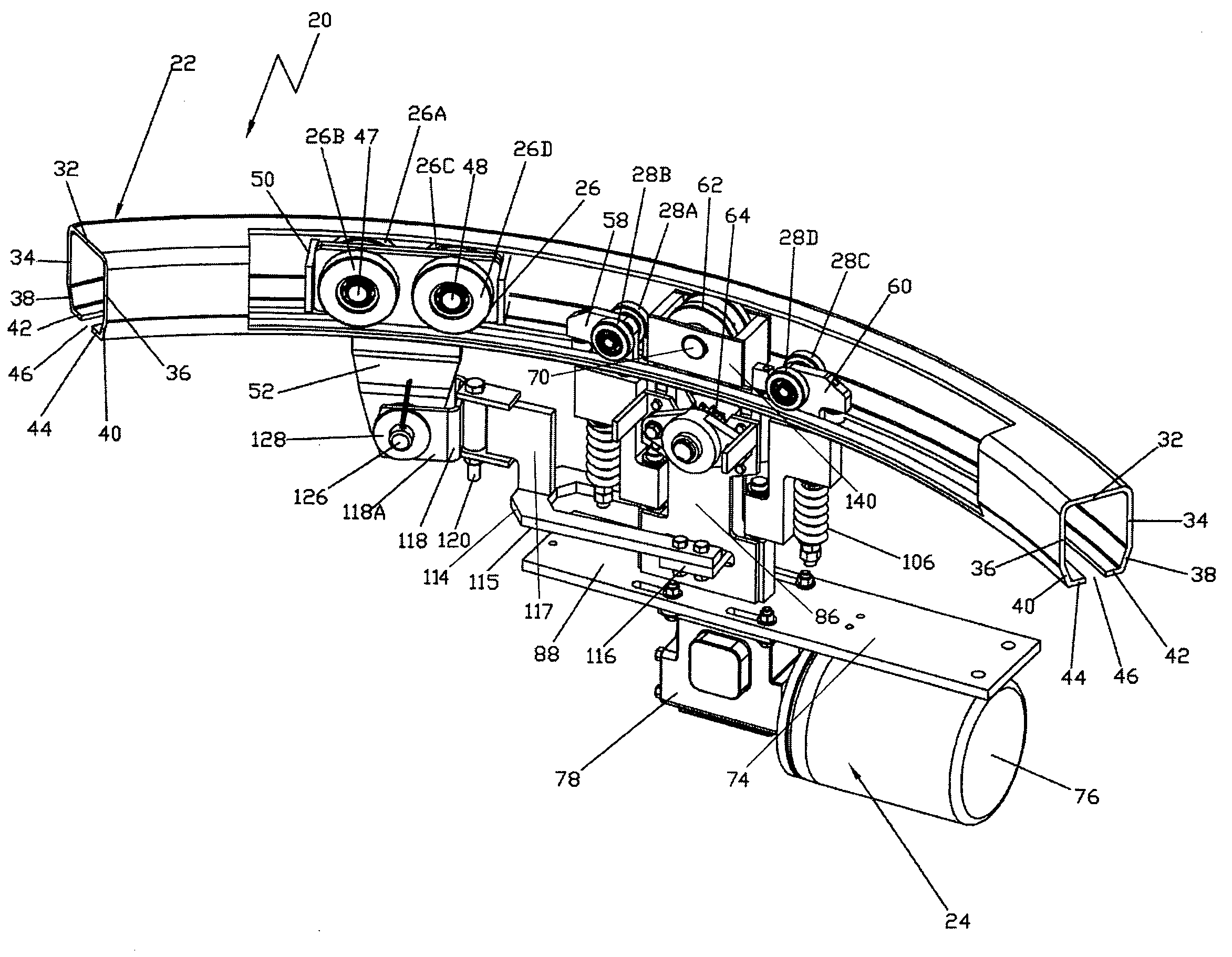

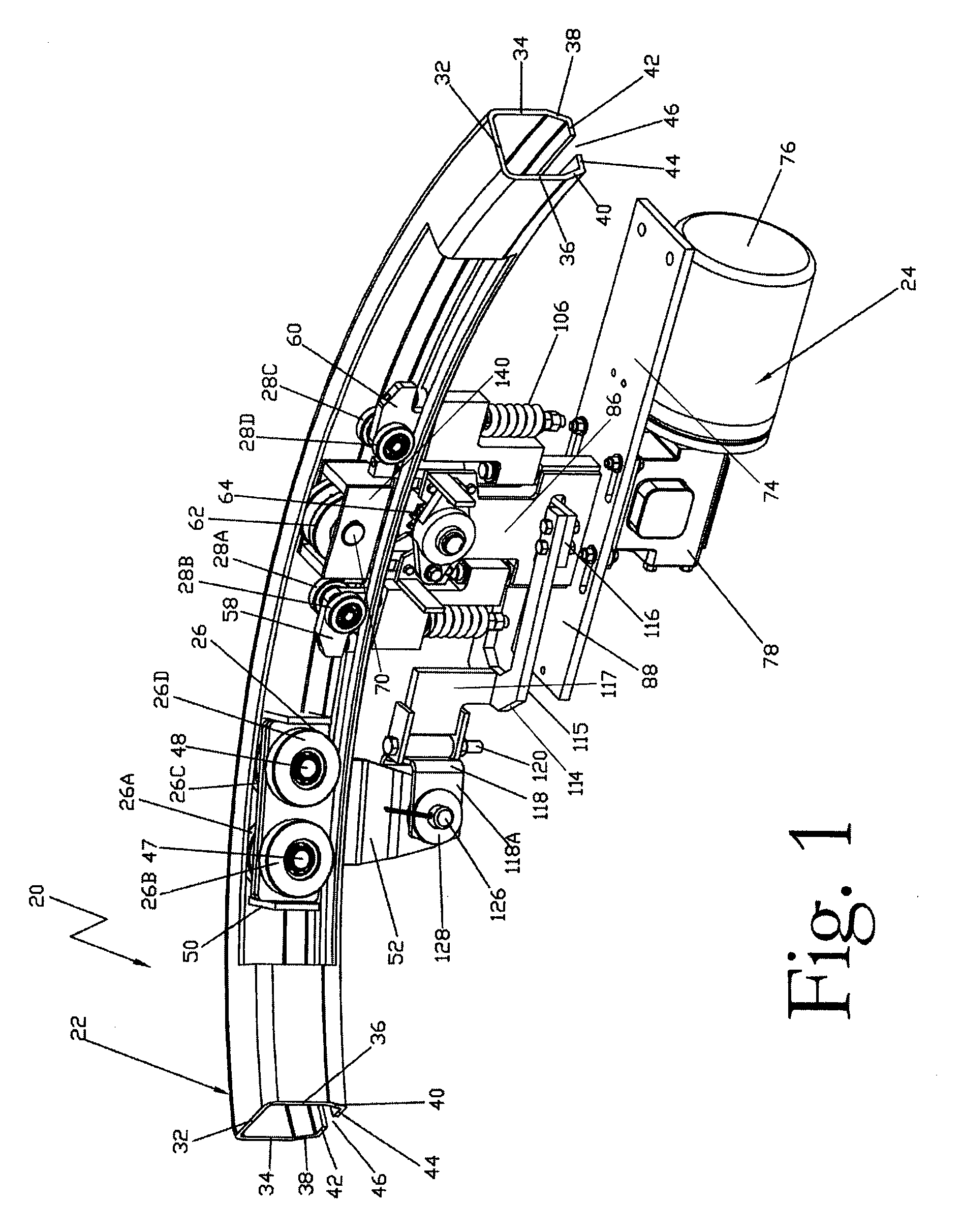

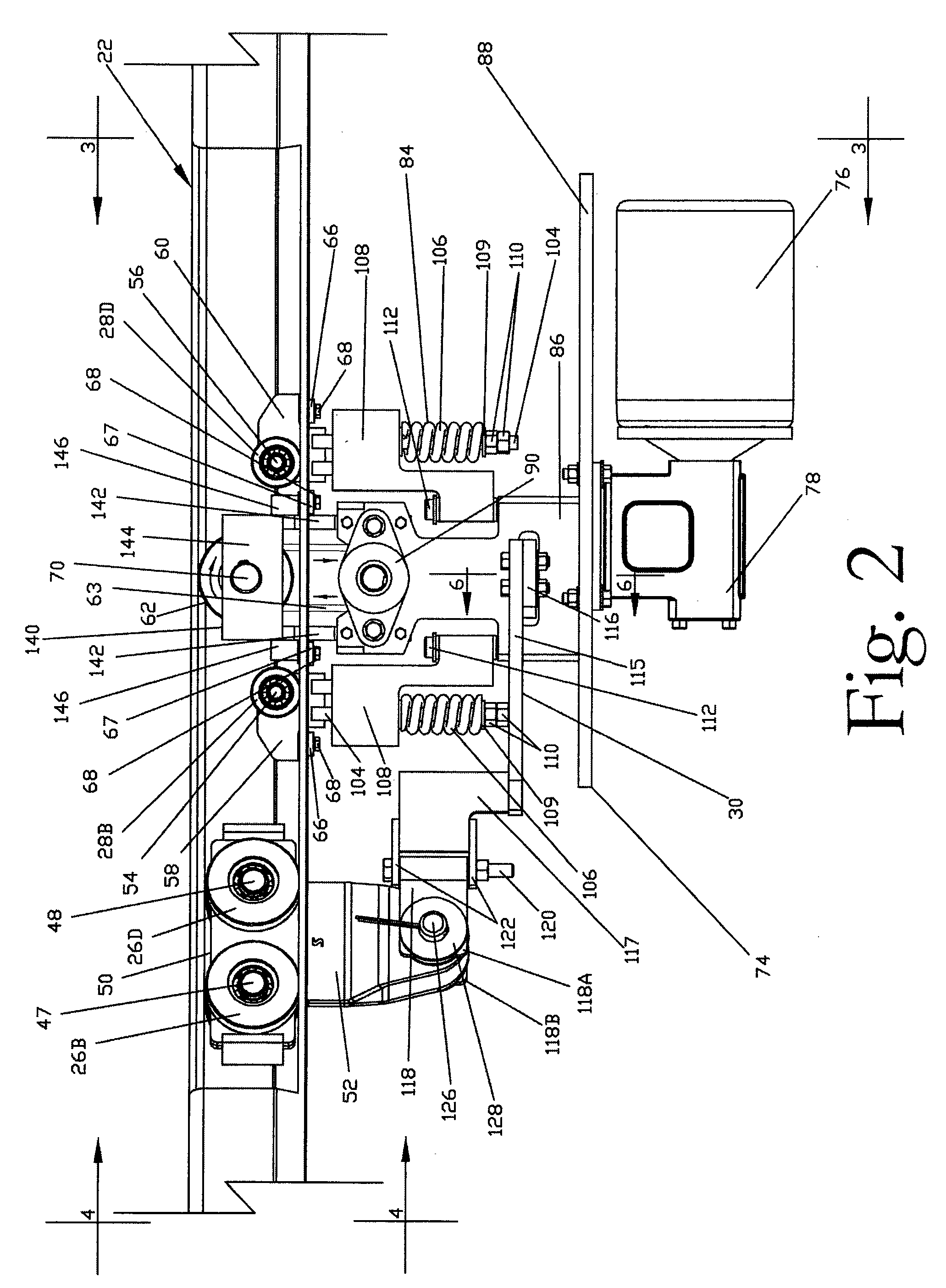

[0024]In FIG. 1 there is shown at 20 one exemplary embodiment of an enclosed track system constructed in accordance with this invention. The system 20 includes a conventional enclosed track 22 and a tractor-drive trolley 24. The details of the trolley 24 will be described later. Suffice it for now to state that the trolley 24 includes two internal roller sections 26 and 28 arranged to be located within the track 22, and an articulated externally located tow-arm assembly 30, The tow-arm assembly 30 is located outside of, i.e., below, the track 22 and is coupled to the both internal roller sections for moving the trolley along the track.

[0025]Turning now to FIGS. 1 and 5, the details of the track 22 will now be discussed. As can be seen the track is of the conventional “enclosed-type” construction. One particularly suitable enclosed track is that sold by SPANCO, a division of Transol Corporation, the assignee of the invention. The track 22 is an elongated member that can be linear or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com