Method, System, and Apparatus of Cutting Earthen Formations and the like

a technology of earthen formations and cutting methods, applied in earth drilling and mining, drill bits, construction, etc., can solve problems such as time and money-consuming, failure rate of entire drill bit, and failure of bit failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

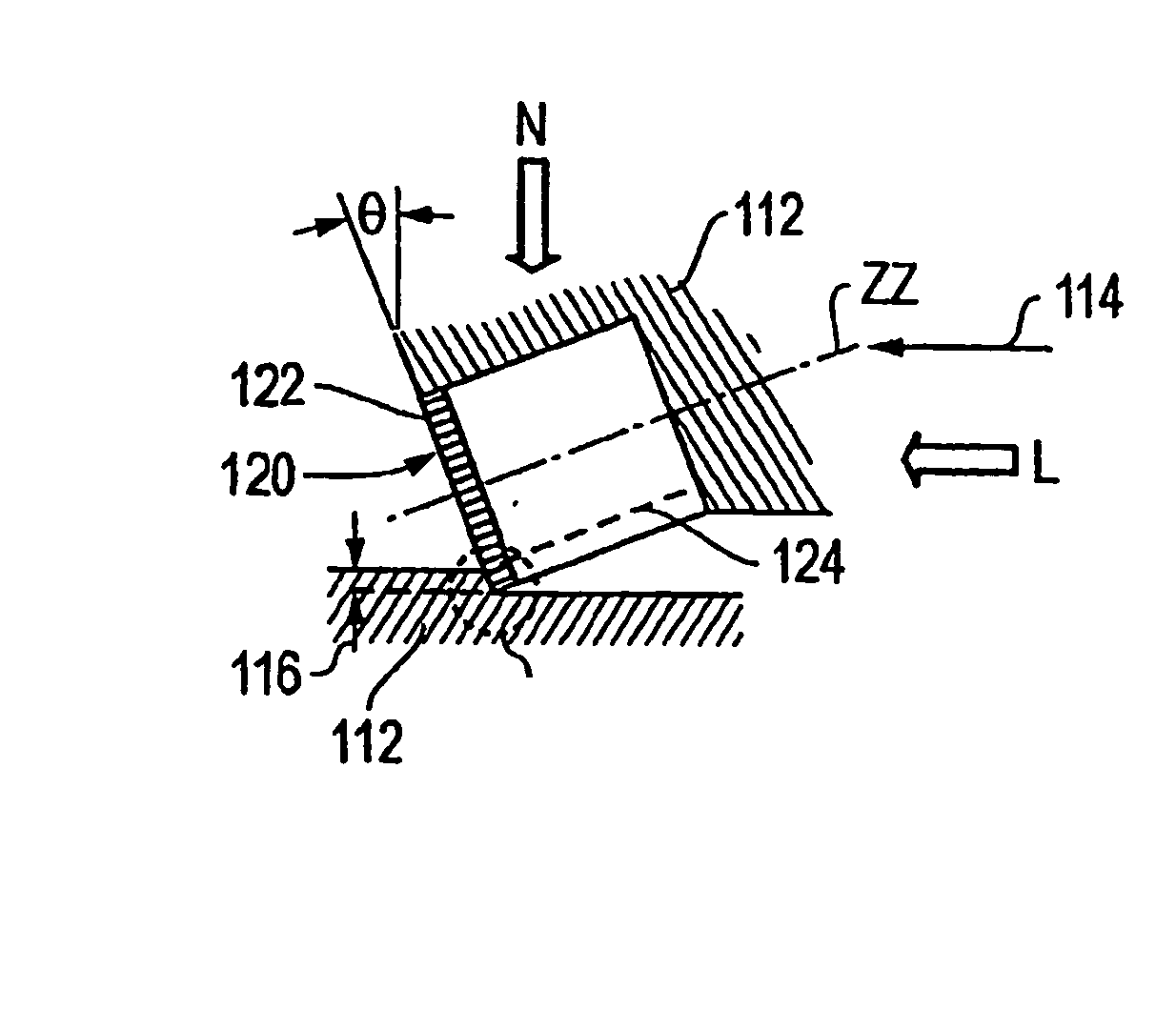

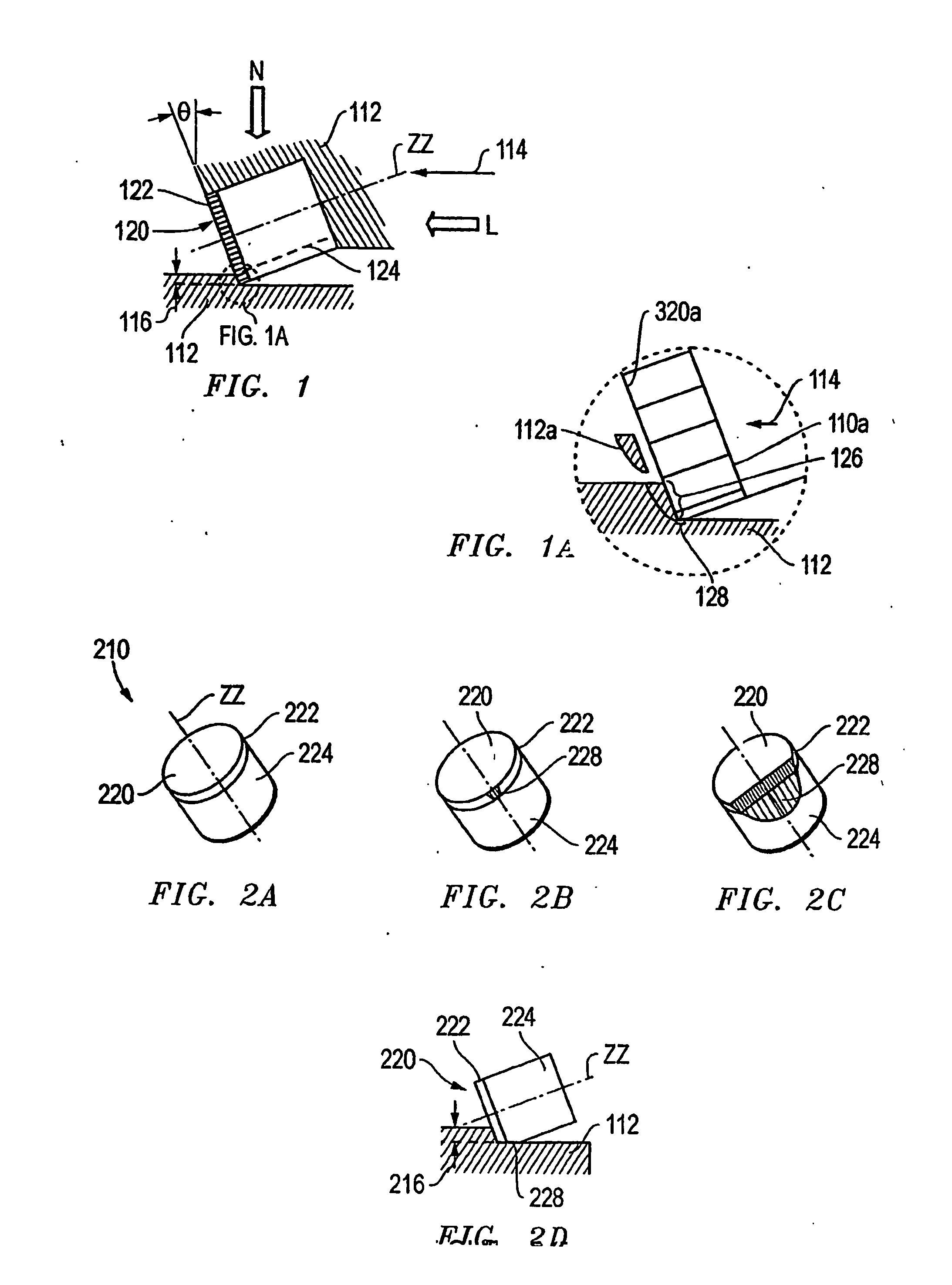

Embodiment Construction

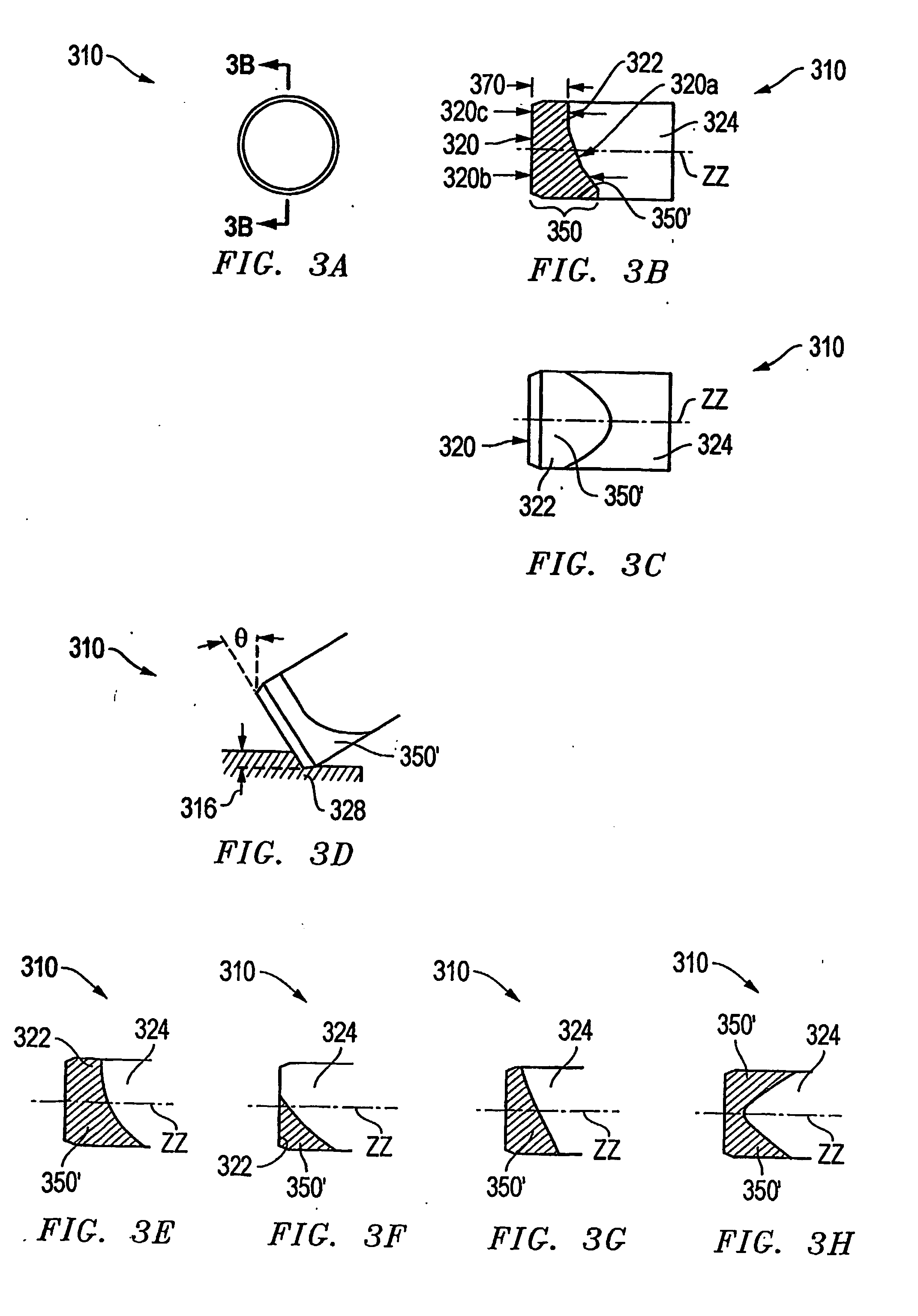

[0024]FIGS. 3A, 3B, and 3C provide front, longitudinal (vertical) cross-sectional, and bottom views, respectively of a cutting element or cutter 310 according to the present invention. The longitudinal axis ZZ may be described as dividing the cross-section into two halves.

[0025]The cutter 310 has a front or cutting face 320 outlined by a circumference or peripheral edge 320a (which may be a chamfered, beveled, or straight edge), and the longitudinal axis, ZZ, extending from the center of the cutting face 320 and generally normal thereto. The cutter 310 includes a substantially forward cutting portion 322 that is preferably comprised of polycrystalline diamond material and thus, referred to as a diamond table. In other embodiments, the material for the cutting portion may be tungsten carbide, cubic boron nitride, or other commonly used materials. The cutter 310 further includes a substantially rearward portion provided by a substrate 324. The substrate 324 is preferably formed from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com